Crystalline silicon cutting fluid as well as preparation method and application thereof

A technology of crystal silicon cutting and alcohols, which is applied in the field of crystal silicon cutting fluid and its preparation, and can solve problems such as high temperature, high surface friction, and lack of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

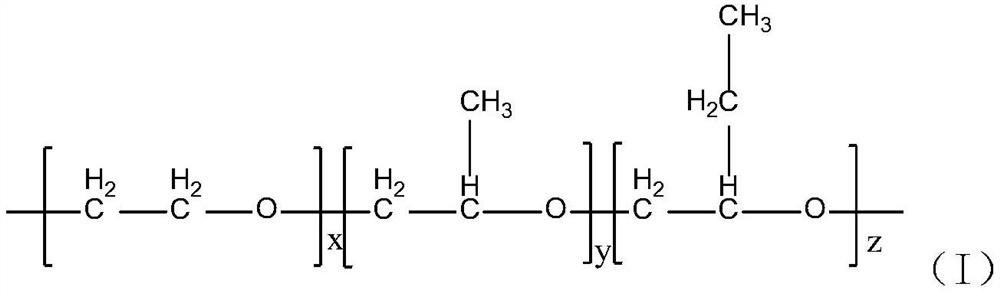

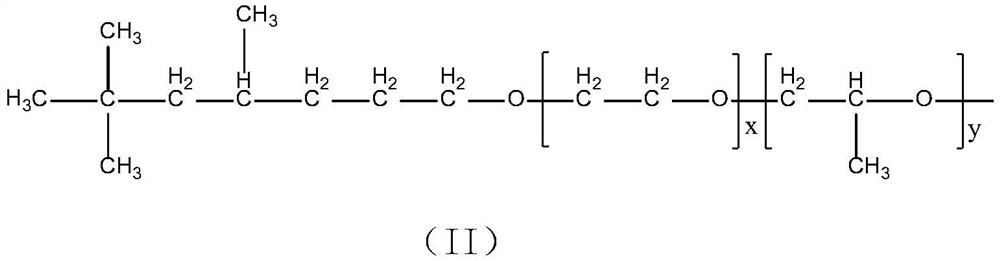

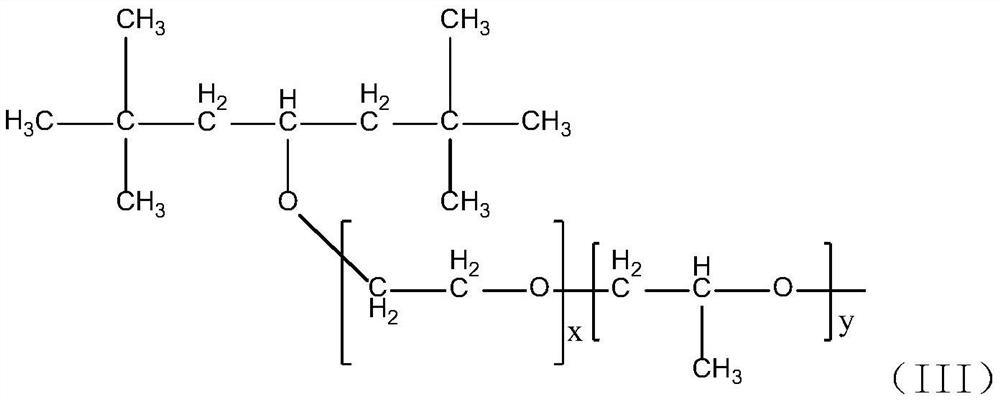

Method used

Image

Examples

Embodiment 1

[0059] Prepare 1000g of cutting fluid suitable for M12 crystal silicon (15-inch silicon wafer), the composition of the raw materials is as follows:

[0060] Take 200g of polymer block polyether, 100g of alcohol wetting agent A, 50g of alcohol wetting agent B, and 650g of deionized water;

[0061] Stir at room temperature for 5 minutes until clear and transparent;

[0062] Pour the prepared cutting fluid into a slicer at room temperature and mix it with water at a ratio of 1:300. Cut with 43 wires. The silicon rod is a square rod or quasi-square rod of 210mm×210mm. The length of the whole silicon rod is about 850mm. It takes 90 minutes to cut silicon wafers with a size of 210mm×210mm.

Embodiment 2

[0064] Prepare 1000g of cutting fluid suitable for M12 crystal silicon (15-inch silicon wafer), the composition of the raw materials is as follows:

[0065] Take 150g of polymer block polyether, 120g of alcohol wetting agent A, 30g of alcohol wetting agent B, and 700g of deionized water;

[0066] Stir at room temperature for 5 minutes until clear and transparent;

[0067] Pour the prepared cutting fluid into a slicer at room temperature and mix it with water at a ratio of 1:300. Cut with 43 wires. The silicon rod is a square rod or quasi-square rod of 210mm×210mm. The length of the whole silicon rod is about 850mm. It takes 90 minutes to cut silicon wafers with a size of 210mm×210mm.

Embodiment 3

[0069] Prepare 1000g of cutting fluid suitable for M12 crystal silicon (15-inch silicon wafer), the composition of the raw materials is as follows:

[0070] Take 250g of polymer block polyether, 150g of alcohol wetting agent A, 20g of alcohol wetting agent B, and 580g of deionized water;

[0071] Stir at room temperature for 5 minutes until clear and transparent;

[0072] Pour the prepared cutting fluid into a slicer at room temperature and mix it with water at a ratio of 1:300. Cut with 43 wires. The silicon rod is a square rod or quasi-square rod of 210mm×210mm. The length of the whole silicon rod is about 850mm. It takes 90 minutes to cut silicon wafers with a size of 210mm×210mm.

[0073] The relevant experimental data of each embodiment of the present invention are as follows:

[0074] 43 wire cutting experimental data

[0075] Example Delivery rate Yield TTV Line marks silicon fall Failure rate Dirty condition Spill Example 1 99.80% 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com