Photoactivated implant surface decontamination sol, and preparation method and application thereof

An implant and photoactivation technology, applied in the fields of application, chemical instruments and methods, botanical equipment and methods, etc., to achieve the effect of easy acquisition of raw materials, scientific design, and enhanced osteogenic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

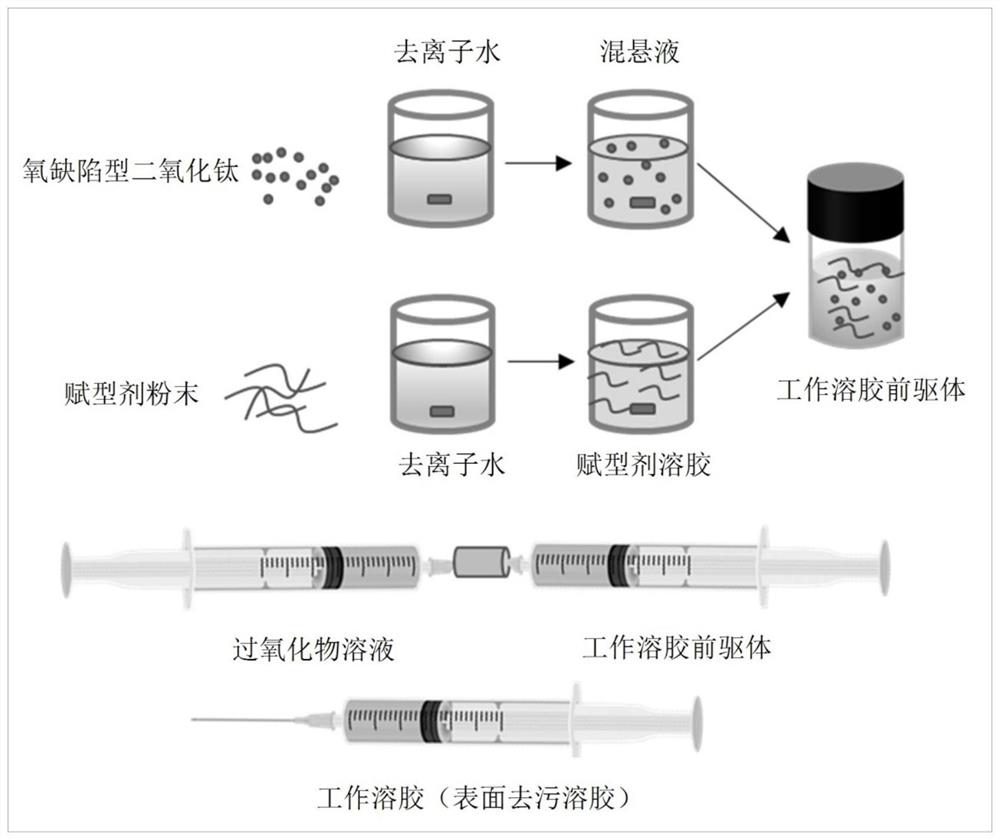

[0053] This embodiment discloses the preparation method of the light-activated implant surface decontamination sol of the present invention, and its preparation process is as attached figure 1 shown. Its preparation method is specifically:

[0054] Step 1. Prepare excipient sol: take an appropriate amount of sodium alginate, dissolve it in deionized water under the action of magnetic stirring, and form an excipient sol with a mass concentration of 6%, and set aside;

[0055] Step 2. Take a certain amount of oxygen-deficient titanium dioxide and disperse it in deionized water, stir it evenly with magnetic force at room temperature, and then disperse it further with ultrasound to prepare a suspension of 80 mg / mL for later use;

[0056] Step 3. Mix the suspension prepared in step 2 with the excipient sol prepared in step 1 in a volume ratio of 1:1, stir evenly at room temperature, sonicate, let stand, continue to stir, sonicate, and repeat this 3 times, Prepare working sol prec...

Embodiment 2

[0059] This embodiment discloses the preparation method of the light-activated implant surface decontamination sol of the present invention, specifically:

[0060] Step 1. Preparation of excipient sol: Take an appropriate amount of carbomer, dissolve it in deionized water under the action of magnetic stirring, adjust the pH to 5-7, and form an excipient sol with a mass concentration of 1% for later use;

[0061] Step 2. Take a certain amount of oxygen-deficient titanium dioxide and disperse it in deionized water, stir it evenly with magnetic force at room temperature, and then disperse it further with ultrasound to prepare a 100 mg / mL suspension for later use;

[0062] Step 3. Mix the suspension prepared in step 2 with the excipient sol prepared in step 1 at a volume ratio of 2:1, stir evenly at room temperature, sonicate, let stand, continue to stir, sonicate, and repeat this 3 times, Prepare working sol precursor;

[0063] Step 4. Inhale the working sol precursor prepared i...

Embodiment 3

[0065] This embodiment discloses the preparation method of the light-activated implant surface decontamination sol of the present invention, specifically:

[0066] Step 1. Prepare excipient sol: take an appropriate amount of carbomer, dissolve it in deionized water under the action of magnetic stirring, and finally form an excipient sol with a mass concentration of 6%, and set aside;

[0067] Step 2. Take a certain amount of oxygen-deficient titanium dioxide and disperse it in deionized water, stir it evenly with magnetic force at room temperature, and then disperse it further with ultrasound to prepare a 150 mg / mL suspension for later use;

[0068] Step 3. Mix the suspension prepared in step 2 with the excipient sol prepared in step 1 in a volume ratio of 3:2, stir evenly at room temperature, sonicate, let stand, continue to stir, sonicate, and repeat this 3 times, Prepare working sol precursor;

[0069] Step 4. Inhale the working sol precursor prepared in step 3 into the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com