Process for performing frozen separation on lactic acid bacteria and making dry powder

A production process, lactic acid bacteria technology, applied in the direction of bacteria, preserved microorganisms, etc., can solve the problems of microbial cell damage, reduce cell biological activity, and reduce the application of freeze-dried powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

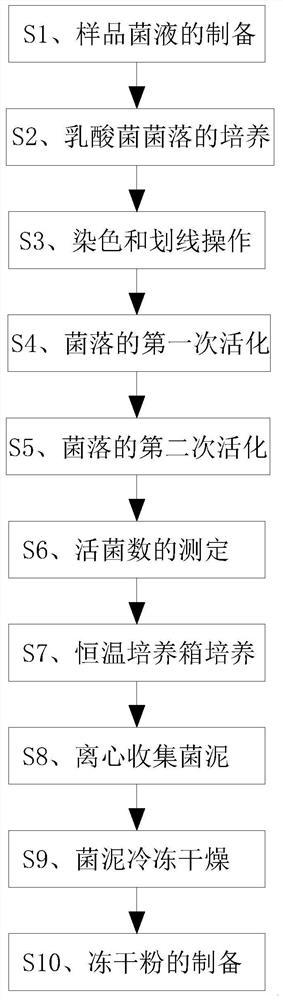

[0030] Please refer to figure 1 Shown, the present invention discloses a kind of lactic acid bacteria freeze separation and dry powder production process, comprises the following steps:

[0031] S1. Preparation of sample bacterial solution: Cut the lactic acid bacteria source sample into pieces, grind, transfer to a centrifuge tube filled with 9mL sterile water or normal saline, vortex or shake the shaker for 10-30min, that is, dilute 10 -1 sample solution, continue to dilute the sample to 10 -3 ,10 -4 and 10 -5 middle;

[0032] S2, the cultivation of lactic acid bacteria colonies: draw 10 in step S1 respectively -3 ,10 -4 and 10 -5 Sample solution 0.2mL, spread on MRS agar medium and operate on 3 plates for each gradient, culture at 37°C for 24 hours to obtain the required lactic acid bacteria colony, MRS agar medium composition: peptone 10g, yeast Cream 5g, beef extract 10g, glucose 20g, dipotassium hydrogen phosphate 2g, triammonium citrate 1g, sodium acetate 5g, mag...

Embodiment 2

[0042] Please refer to figure 1 Shown, the present invention discloses a kind of lactic acid bacteria freeze separation and dry powder production process, comprises the following steps:

[0043] S1. Preparation of sample bacterial solution: Cut the lactic acid bacteria source sample into pieces, grind, transfer to a centrifuge tube filled with 9mL sterile water or normal saline, vortex or shake the shaker for 10-30min, that is, dilute 10 -1 sample solution, continue to dilute the sample to 10 -3 ,10 -4 and 10 -5 middle;

[0044] S2, the cultivation of lactic acid bacteria colonies: draw 10 in step S1 respectively -3 ,10 -4 and 10 -5 Sample solution 0.2mL, spread on MRS agar medium and operate on 3 plates for each gradient, culture at 37°C for 36 hours to obtain the required lactic acid bacteria colony, MRS agar medium composition: peptone 10g, yeast Cream 5g, beef extract 10g, glucose 20g, dipotassium hydrogen phosphate 2g, triammonium citrate 1g, sodium acetate 5g, mag...

Embodiment 3

[0054] Please refer to figure 1 Shown, the present invention discloses a kind of lactic acid bacteria freeze separation and dry powder production process, comprises the following steps:

[0055] S1. Preparation of sample bacterial solution: Cut the lactic acid bacteria source sample into pieces, grind, transfer to a centrifuge tube filled with 9mL sterile water or normal saline, vortex or shake the shaker for 10-30min, that is, dilute 10 -1 sample solution, continue to dilute the sample to 10 -3 ,10 -4 and 10 -5 middle;

[0056] S2, the cultivation of lactic acid bacteria colonies: draw 10 in step S1 respectively -3 ,10 -4 and 10 -5 Sample solution 0.2mL, spread on MRS agar medium and operate on 3 plates for each gradient, culture at 37°C for 48 hours to obtain the required lactic acid bacteria colony, MRS agar medium composition: peptone 10g, yeast Cream 5g, beef extract 10g, glucose 20g, dipotassium hydrogen phosphate 2g, triammonium citrate 1g, sodium acetate 5g, mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com