Antibacterial fabric and preparation method thereof

An antibacterial fabric and fabric technology, which is applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., can solve problems such as poor safety, poor high temperature stability of antibacterial fabrics, and unsustainable antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

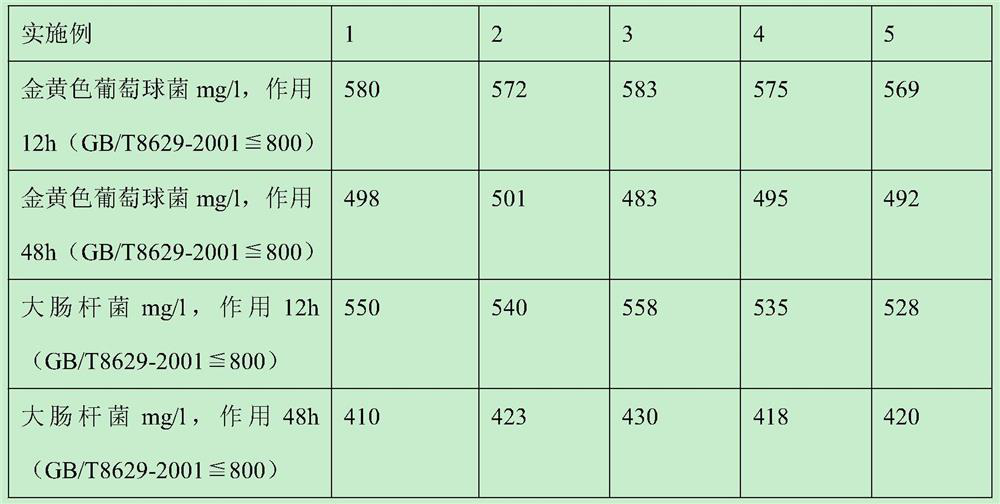

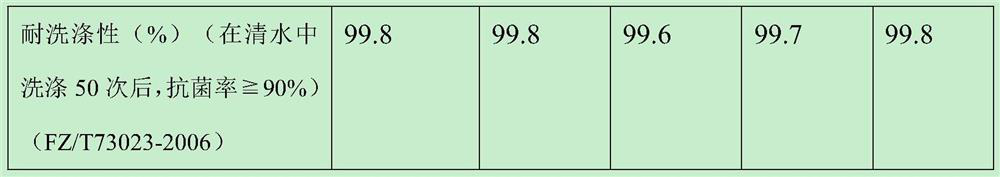

Examples

preparation example Construction

[0026] The present invention also provides a kind of preparation method of antibacterial fabric, comprises the following steps:

[0027] Step (1) Preparation of N-2-hydroxypropyltrimethylammonium chloride chitosan: chitosan is dissolved in dilute acetic acid solution, and glycidyltrimethylammonium chloride is added to the reaction system, the shell The molar ratio of polysaccharide to glycidyltrimethylammonium chloride is 1:5, then adjust the pH value of the solution to 6.0-6.5 with dilute hydrochloric acid, and react at 85°C for 14 hours. After the reaction, the product is precipitated with ethanol. Filter, and finally wash the product with 70% ethanol aqueous solution to obtain a crude product, dissolve the crude product in water, and filter with a sand core funnel, the filtrate is precipitated with acetone, and the solid final product N-2-hydroxypropyl trimethyl is obtained after filtering again ammonium chloride chitosan.

[0028] Step (2) emulsification reaction: take a ...

Embodiment 1

[0034] The invention provides an antibacterial fabric, comprising a fabric substrate, the fabric substrate is regenerated fiber, and a composite microcapsule antibacterial agent is added to the fabric substrate; the raw material components of the composite microcapsule antibacterial agent and the components thereof Parts by weight: 5 parts of N-2-hydroxypropyltrimethylammonium chloride chitosan, 2 parts of luohan cedar oil, 2 parts of fennel oil, 25 parts of gelatin, 10 parts of n-nonane, glutaraldehyde crosslinking agent 0.5 parts, 5 parts of 10% sodium hydroxide aqueous solution, 2 parts of calcium chloride dihydrate, 0.5 parts of emulsifier OP-100, 10 parts of modified acrylic resin, and 80 parts of distilled water.

[0035] The present invention also provides a kind of preparation method of antibacterial fabric, comprises the following steps:

[0036] Step (1) Preparation of N-2-hydroxypropyltrimethylammonium chloride chitosan: chitosan is dissolved in dilute acetic acid s...

Embodiment 2

[0042] An antibacterial fabric, comprising a fabric base material, the fabric base material is a synthetic fiber, and a composite microcapsule antibacterial agent is added in the fabric substrate; the raw material components of the composite microcapsule antibacterial agent and the parts by weight of the components thereof For: 10 parts of N-2-hydroxypropyltrimethylammonium chloride chitosan, 5 parts of luohan cedar oil, 5 parts of fennel oil, 40 parts of gelatin, 15 parts of n-nonane, 1 part of glutaraldehyde crosslinking agent, 8 parts of 10% sodium hydroxide aqueous solution, 4 parts of calcium chloride dihydrate, 1 part of emulsifier PVA, 15 parts of amino resin, and 100 parts of distilled water. The preparation method of this antibacterial fabric is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com