Boiler close-to-wall air device and method based on burner near-wall atmosphere soft measurement

A wall-adhering wind and burner technology is applied in the field of boiler combustion, which can solve the problems of complex equipment, large investment, and damage to measuring components of the real-time monitoring system for atmosphere near the wall, achieving significant technical and economic benefits, simple and reasonable system structure, Ease of retrofit implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

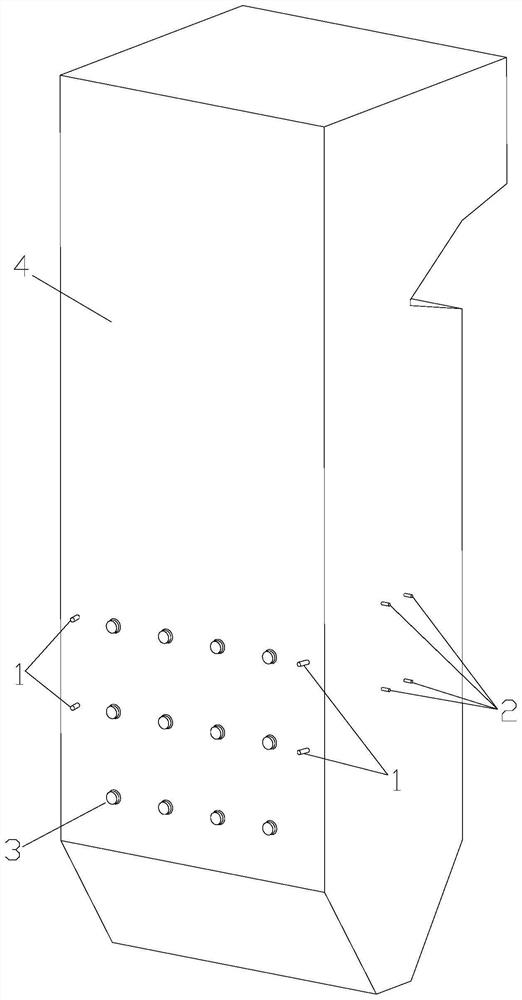

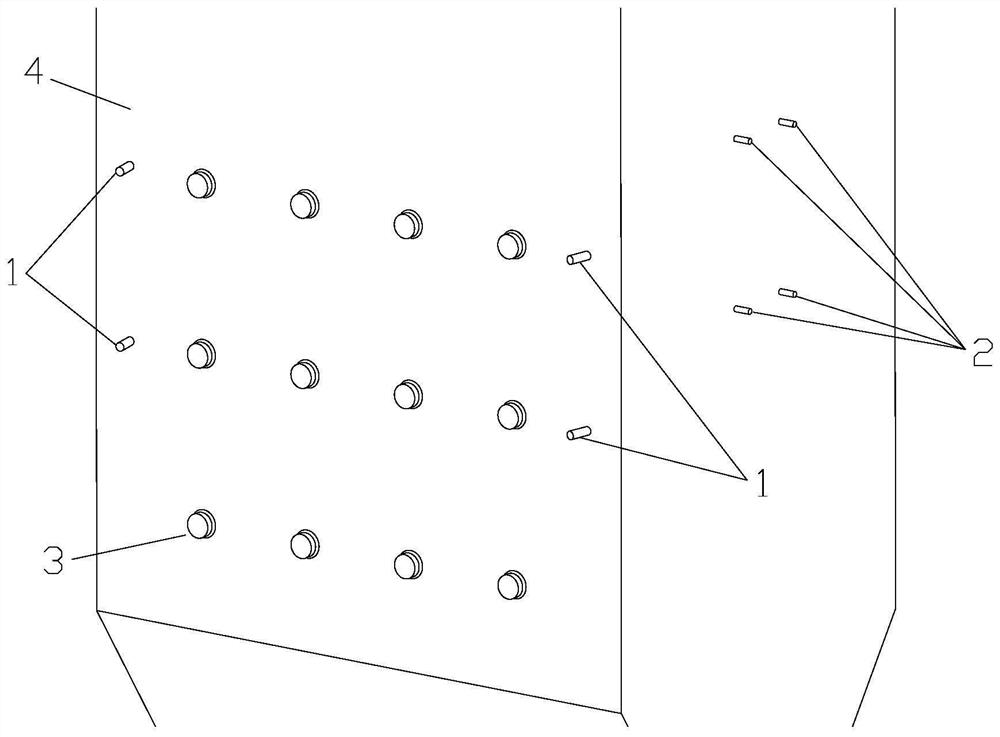

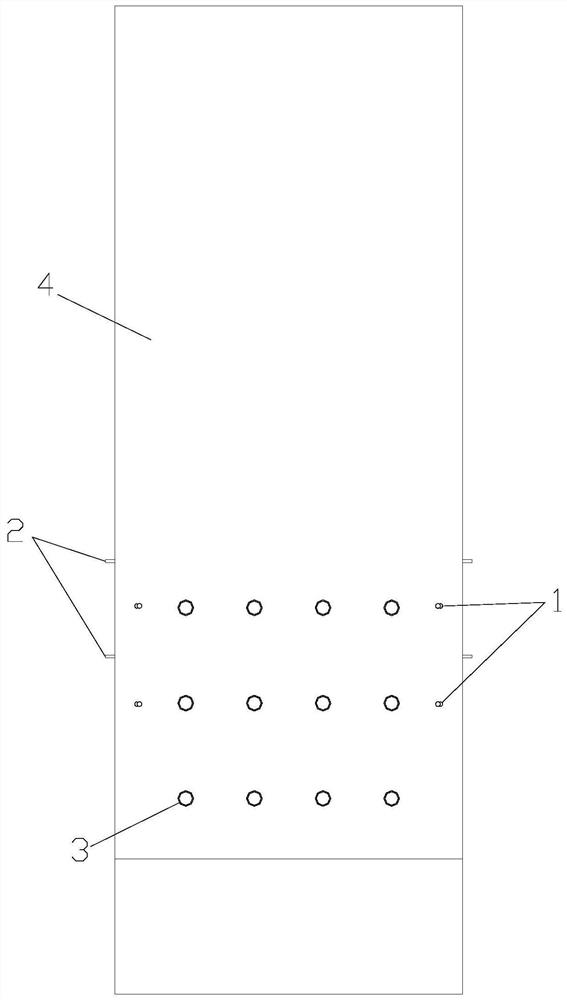

[0055] Such as Figure 1-Figure 6 As shown, the boiler close-to-wall wind device based on the soft measurement of the atmosphere near the wall of the burner includes the close-to-wall wind nozzle 1 , the near-wall atmosphere sampling tube 2 , the burner 3 and the furnace 4 . A boiler whose front and rear walls are opposed, add 2-5 layers of wall-mounted air nozzles 1 on the front and rear walls near the burner at the bottom of the furnace 4, and set the near-wall atmosphere sampling tube 2 on the side wall of the furnace 4.

[0056] As a preferred embodiment, the near-wall atmosphere sampling tube 2 is installed on the left and right side walls of the furnace 4, and its height is located in the middle and upper part of the burner area. It is made of heat-resistant stainless steel and installed on the fins of the water wall. 20mm, 2-4 layers in total. The near-wall atmosphere sampling pipe 2 can be connected to a flue gas analyzer after flue gas pretreatment.

[0057] As a pr...

Embodiment 2

[0059] Such as Figure 7-9 As shown, the method for using the boiler wall-attached wind device based on the soft measurement of the atmosphere near the wall of the burner comprises the following steps:

[0060] S1. First, connect the near-wall atmosphere sampling tube 2 to the flue gas analyzer, and conduct a short-term (5-15 days) off-line measurement of the near-wall atmosphere at each measuring point under the condition of adjusting different boiler operating parameters and wall-attached wind parameters. The obtained data is used to train the least squares support vector machine prediction model to obtain relevant parameters in the model, such as Figure 7 shown.

[0061] As a preferred embodiment, boiler operating parameters include: boiler load; main steam pressure and flow rate; coal quality parameters; input combination of coal mill; blade angle and damper opening of each layer of burner; furnace outlet temperature and oxygen content; Tail NOx emission value; furnace ...

Embodiment 3

[0083] Using ANSYS Fluent to conduct flow and thermal combustion numerical simulation experiments on the boiler wall-attached air device based on the soft measurement of the atmosphere near the burner wall, and analyze the effect of the wall-attached air:

[0084] 1) Calculate boundary conditions

[0085] Taking a 660MW supercritical boiler as the simulation object, the boiler adopts a medium-speed coal mill positive pressure cold primary air direct-blown pulverizing system, and the front and rear walls oppose the combustion method. There are 6 coal mills in total, and the fuel is bituminous coal. The boiler load is 100%.

[0086] 2) Calculation model

[0087] The turbulence model is Realizable k-ε, the radiation model adopts the DO model, and the combustion reaction adopts the prePDF method.

[0088] 3) Calculation result

[0089] Through numerical simulation, it is found that Figure 10 As shown, when the wall-adhering wind is closed, the near-wall O 2 The concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com