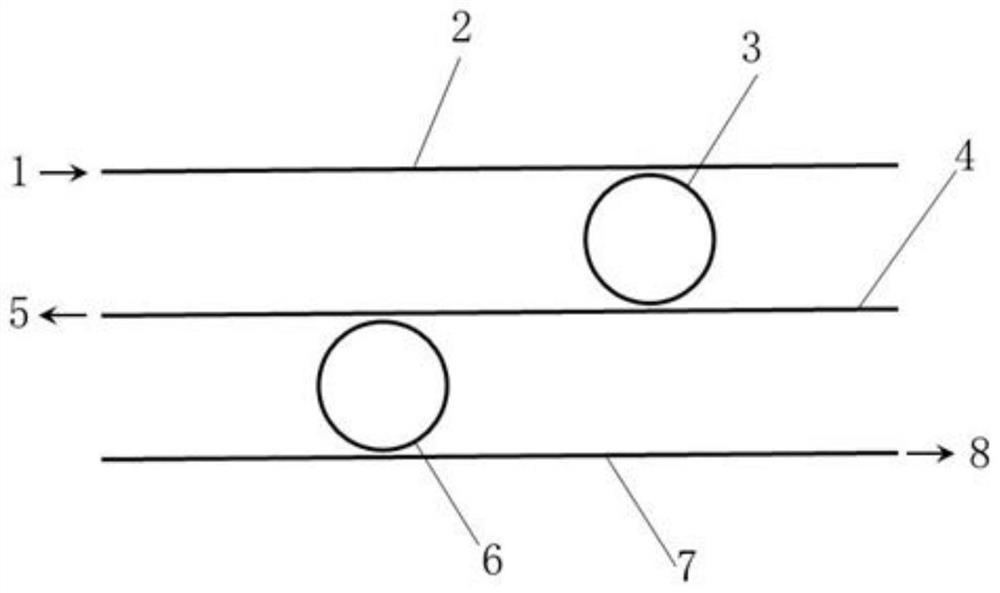

Preparation method of PAMAM silicon-based cascade double-ring resonant cavity chip for detecting PCA3

A double-ring resonance and cascading technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of not observing the signal changes of cascaded double-ring resonant cavity sensors, the inability to realize PCA3 selective detection, and the small number of PCA3 gene probes, etc. , to increase the quantity, reduce the detection cost, enhance the signal strength and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Clean the silicon-based cascaded double-ring resonator with acetone, ethanol, and deionized water in sequence for 15 minutes, and then perform plasma treatment for 5 minutes at a power of 10.2w and a vacuum of 50pa (about 375mTor). The sensing ring of the silicon-based cascaded double-ring resonator was treated with 95% ethanol containing 2% (volume percentage) 3-(2,3-epoxypropoxy)propyltrimethoxysilane dropwise for 1 h, and then the Put the sensing ring into 15ml of DMSO solution containing 0.5g of G3PAMAM, and react at 100°C for 4h. Next, the sensing ring was put into 10 ml of DMSO solution containing 2.5 g of succinic anhydride and 0.15 g of DMAP, which was blown with nitrogen, and reacted at room temperature for 24 h. Then transfer the sensing loop to the newly prepared 0.04MEDC / 0.01M NHS solution and let it stand for 1h, then transfer to the NH solution containing 1μM PCA3 probe. 2 -(CH 2 ) 6 -AAAAATTGTTCAAAGACCCTTCGTGTT was reacted overnight in a PBS solution a...

Embodiment 2

[0068] Clean the silicon-based cascaded double-ring resonator with acetone, ethanol, and deionized water in sequence for 15 minutes, and then perform plasma treatment for 5 minutes at a power of 10.2w and a vacuum of 50pa (about 375mTor). The surface of the sensing ring of the silicon-based cascaded double-ring resonator was treated with anhydrous toluene solution containing 1% (volume percentage) of 3-(2,3-epoxypropoxy)propyltriethoxysilane for 30 minutes, and then After drying at 110° C. for 1 h, the sensing loop was put into 5 ml of methanol solution containing 10% (mass percent) G4 PAMAM, and reacted at 100° C. for 10 h. Then put the sensing loop into 10ml of nitrogen gas containing 30mM NaIO 4 The solution was reacted for 2h. Then the sensing loop was transferred to a freshly prepared 1% glutaraldehyde solution for 1 h, and then transferred to 1 μM PCA3 probe NH 2 -(CH 2 ) 6 -AAAAACTGCTGACTTTACCATCTGAGGCCAC was reacted overnight in a PBS solution at 4° C. to prepare a...

Embodiment 3

[0070]Clean the silicon-based cascaded double-ring resonator with acetone, ethanol, and deionized water in sequence for 15 minutes, and then perform plasma treatment for 5 minutes at a power of 10.2w and a vacuum of 50pa (about 375mTor). Add 10% (volume percent) 3-aminopropyltriethoxysilane aqueous solution (pH3-4) dropwise to the sensing ring of the silicon-based cascaded double-ring resonator and treat it at 75°C for 1 hour, then put the sensing ring into 5% glutaraldehyde solution at room temperature for 0.5 hours. After washing with 0.01MPBS (0.137MNaCl, pH7.4) buffer solution, the sensing loop was put into 5ml aqueous solution containing 150mg G5 PAMAM, and reacted at room temperature for 2h. Add 0.3 g of sodium borohydride and stir at room temperature for 36 hours. Next, the sensing ring was put into 4 ml of THF solution containing 51.6 mg of succinic anhydride and 15.7 mg of DMAP which was blown with nitrogen, and reacted at 40° C. for 4 h. Then transfer the sensing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com