Preparation method of cellulose silicon-based cascade double-ring resonant cavity chip for detecting PCA3

A double-ring resonance, cellulose technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems such as the inability to observe the change of the signal of the cascaded double-ring resonator cavity sensor, the inability to realize the selective detection of PCA3, and the small number of PCA3 gene probes. , to achieve the effect of safer and more environmentally friendly operation process, lower testing costs, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The cellulose used in the preparation of the cellulose film in the present invention is cellulose and cellulose derivatives such as cellulose, carboxylated cellulose, polymerized cellulose, hydroxypropylmethylcellulose, and hydroxyethylcellulose.

[0049] The prepared cellulose film may further include cellulose copolymers or blends doped with other nanoparticles.

[0050] The fixation of the PCA3 probe in the present invention is to fix the PCA3 probe on the surface of the cellulose film through the covalent reaction of the PCA3 probe and the cellulose.

[0051] The PCA3 probe of the present invention is designed using the 4 exons of PCA3 as a template.

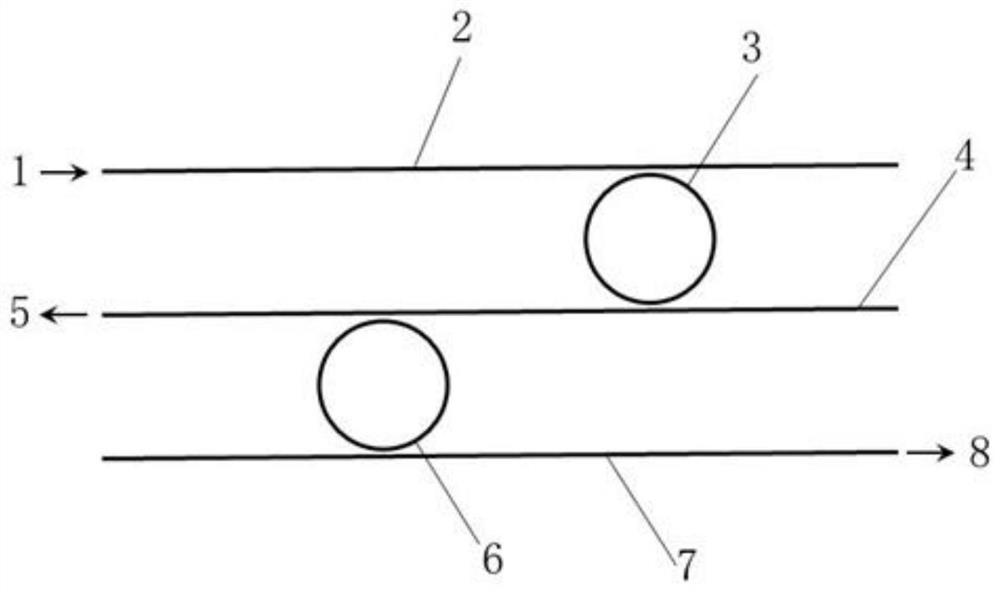

[0052] The process of modifying the PCA3 probe on the surface of the sensing ring 6 of the present invention comprises the following steps:

[0053] ① Pretreatment of silicon-based cascaded double-ring resonators;

[0054] ② Modification of epoxy silane or amino silane on the surface of sensing ring 6;

[0055] ③ F...

Embodiment 1

[0066] Immerse the silicon-based cascaded double-ring resonant cavity in a piranha solution (98% sulfuric acid: 30% hydrogen peroxide in a ratio of 7:3) and treat it at 80°C for 30 minutes, clean it with ultrapure water, and then immerse it in ammonia water: hydrogen peroxide: water Treat in a solution with a volume ratio of 1:1:5 for 1 h, and wash with ultrapure water. A 2% 3-aminopropyltriethoxysilane solution in toluene was added dropwise to the sensing ring of the silicon-based cascaded double-ring resonator treated above for treatment for 1 h, followed by treatment at 120° C. for 30 min. Then, 5 ml of an aqueous solution containing 0.271 g of carboxymethyl cellulose was put into the sensing ring, and reacted at 90° C. for 15 h. Then the sensing ring was put into 5ml of methanol solution containing 100mg of succinic anhydride, and reacted at room temperature for 24h. Then transfer the sensing loop to the newly prepared EDC / NHS (0.04M:0.01M) solution and let it stand for 1...

Embodiment 2

[0068] Immerse the silicon-based cascaded double-ring resonant cavity in a piranha solution (98% sulfuric acid: 30% hydrogen peroxide in a ratio of 7:3) and treat it at 80°C for 30 minutes, clean it with ultrapure water, and then immerse it in ammonia water: hydrogen peroxide: water Treat in a solution with a volume ratio of 1:1:5 for 1 h, and wash with ultrapure water. The surface of the sensing ring of the above-mentioned liquid-treated silicon-based cascaded double-ring resonator was added dropwise with an anhydrous toluene solution containing 1% 3-(2,3-epoxypropoxy)propyltrimethoxysilane for 30 minutes, After drying at 110° C. for 1 h, the sensing ring was put into 5 ml of DMSO solution containing 0.01 g LiCl and 0.5 g cellulose, and reacted at 80° C. for 24 h. Next, the sensing ring was put into 9 ml of tetrahydrofuran solution containing 25 mg of succinic anhydride and reacted overnight at room temperature for 24 hours. Then transfer the sensing loop to the newly prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com