Atomization assembly for electronic cigarette, preparation method of atomization assembly and electronic cigarette

A technology of atomizing components and electronic cigarettes, which is applied in the field of electronic cigarettes, can solve the problems of insufficient resistance stability and consistency, and achieve the effect of improving uniform stability and maintaining permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

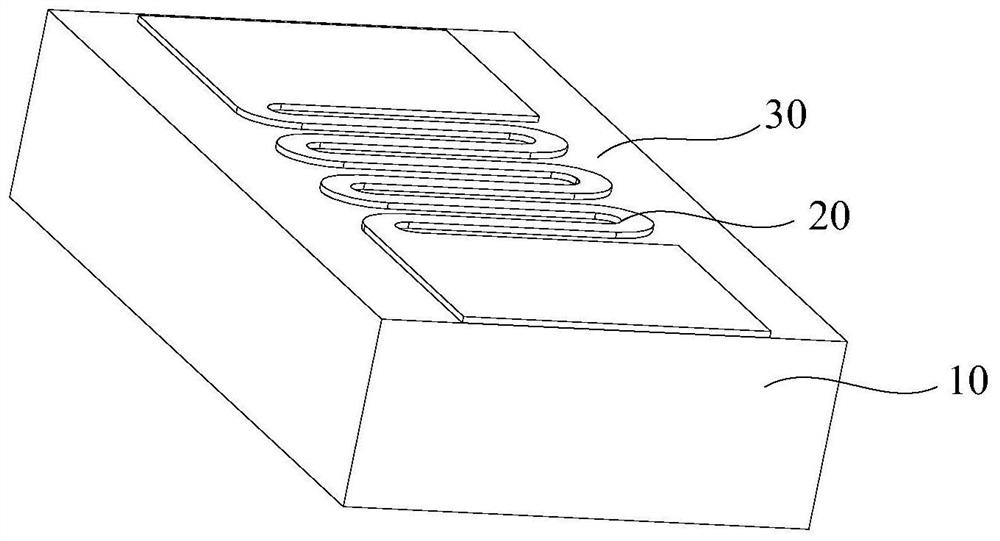

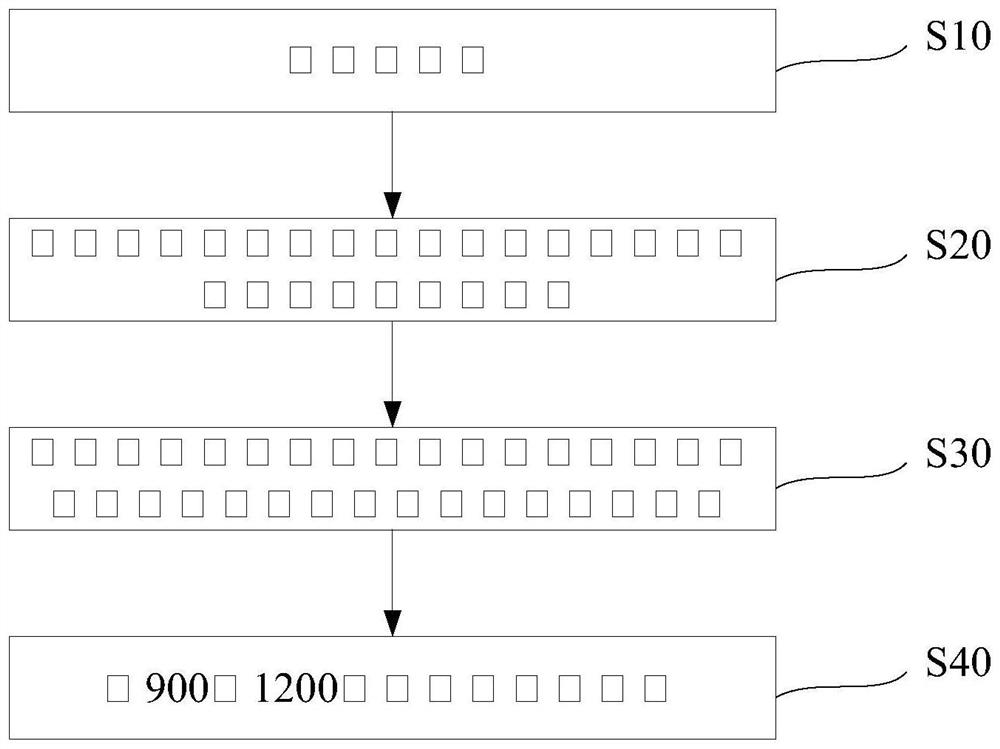

[0043] The preparation method of the atomization assembly proposed in one embodiment, see figure 2 shown, including the following steps:

[0044] S10, obtaining the porous body 10;

[0045] S20, mixing ceramic material powder, electrothermal metal material powder, and sintering aids into a mixed slurry;

[0046] S30, forming a heat-dissipating body layer on the surface of the porous body 10 by coating, printing, casting, etc. the mixed slurry in step S20;

[0047] S40, and then sintering at a temperature of 900-1200 degrees, and the exothermic body layer is transformed into the exothermic material layer 20 .

[0048] Among them, the acquisition of the porous body 10 in step S10 can be prepared by technical personnel by mixing and sintering the conventional inorganic ceramic powder and pore-forming agent; specifically, diatomite, alumina, After mixing inorganic ceramic powder such as zirconia with an appropriate proportion of pore-forming agent, adding an appropriate amount...

Embodiment 1

[0059] S10, obtaining a block-shaped porous body 10 with a size of 3mm×5mm×10mm and an average porosity of 60%;

[0060] S21, wet ball milling the purchased mullite to an average particle size of 100 μm, drying for later use;

[0061] S22, mixing the ball-milled mullite powder and stainless steel powder according to a weight ratio of 10:90 to obtain a mixed powder; then adding 15% ethyl cellulose, 10% propylene glycol monomethyl ether, and phthalate in the mass percentage of the mixed powder Dioctyl formate 3% and paraffin wax 2% are mixed and prepared to obtain a mixed slurry; of course, in order to ensure the uniformity of the slurry, three-roll rolling can be used to mix the mixture, and it is left to stand in a vacuum box for a certain period of time. Time, remove the air bubbles in the slurry;

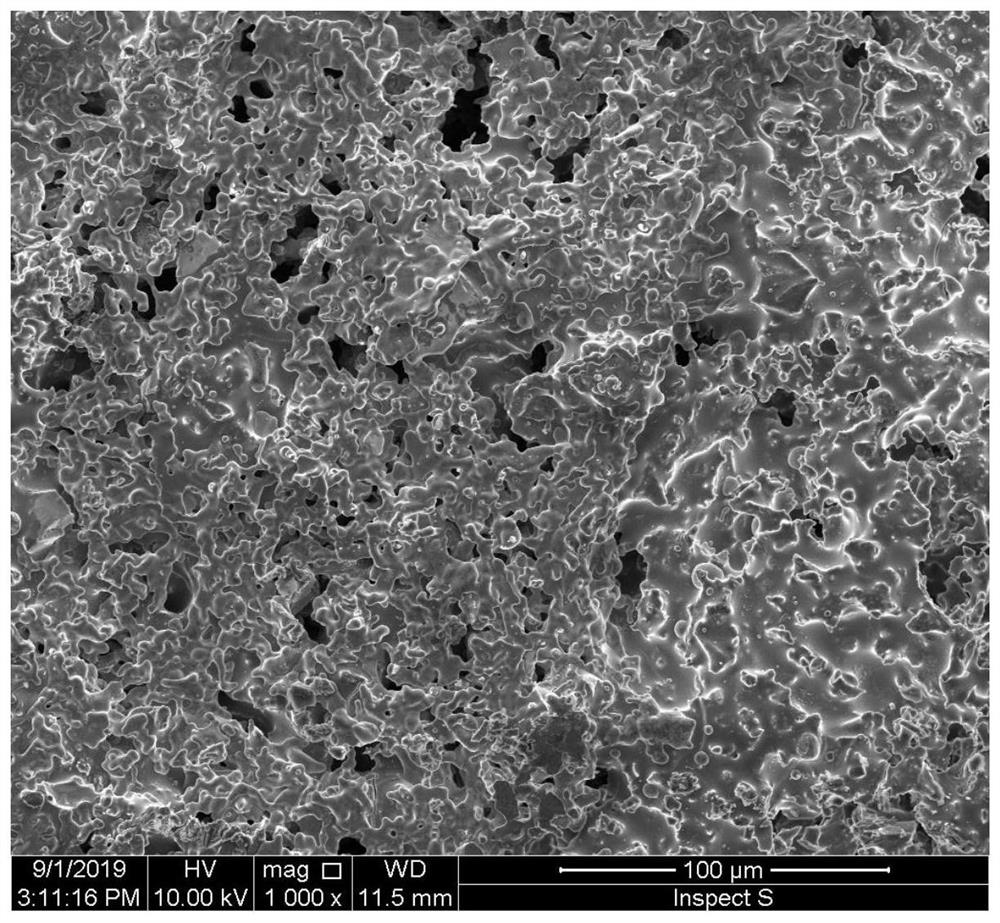

[0062] S30, the mixed slurry in step S22 is printed to form a 100 μm thick heating layer on the surface of the porous body 10, and then placed in the air environment for leveling...

Embodiment 2

[0065] S10, obtaining a block-like porous body 10 with a size of 3mm×5mm×10mm and an average porosity of 48%;

[0066] S21, drying the purchased diatomite powder with an average particle size of 80 μm for subsequent use;

[0067] S22, mixing diatomite powder and nickel-chromium (1:1) alloy powder according to a weight ratio of 5:95 to obtain a mixed powder; then adding 15% of ethyl cellulose and 10% of propylene glycol monomethyl ether in mass percent of the mixed powder , 3% dioctyl phthalate, and 2% paraffin to obtain a mixed slurry; of course, in order to ensure the uniformity of the slurry, three-roll rolling can be used during the mixing process, and the mixture can be mixed in a vacuum box Stand in the middle for a certain period of time to remove the air bubbles in the slurry;

[0068] S30, the mixed slurry in step S22 is printed to form a 90 μm thick heating layer on the surface of the porous body 10, and then placed in the air environment for leveling treatment, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com