Porous spherical carbon adsorption material with blood compatibility and preparation method of porous spherical carbon adsorption material

A blood-compatibility, porous spherical technology, applied in carbon preparation/purification, blood circulation treatment, chemical instruments and methods, etc., can solve problems such as uneven dispersion, inability to exert adsorption performance, and large pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

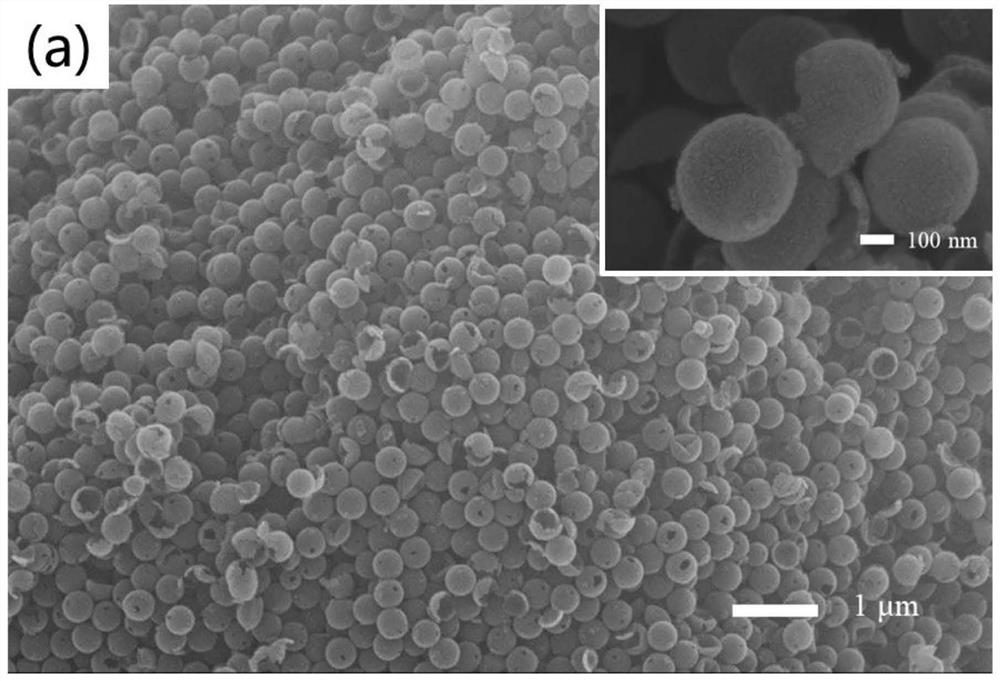

[0051] 1) Prepare a mixed solution of methyl orthosilicate, ethanol, ammonia water and water, stir at 750rpm at 20°C for 180min, then add resorcinol and formaldehyde, the reaction conditions remain unchanged, continue to stir, and after fully reacting for 21h, add The solution is centrifuged, filtered, washed and dried to obtain carbon / silicon composite microspheres;

[0052] 2) Put carbon / silicon composite microspheres into a tube furnace for carbonization, use an argon atmosphere, heat up to 700°C at a heating rate of 5°C / min, and then hold for 3 hours;

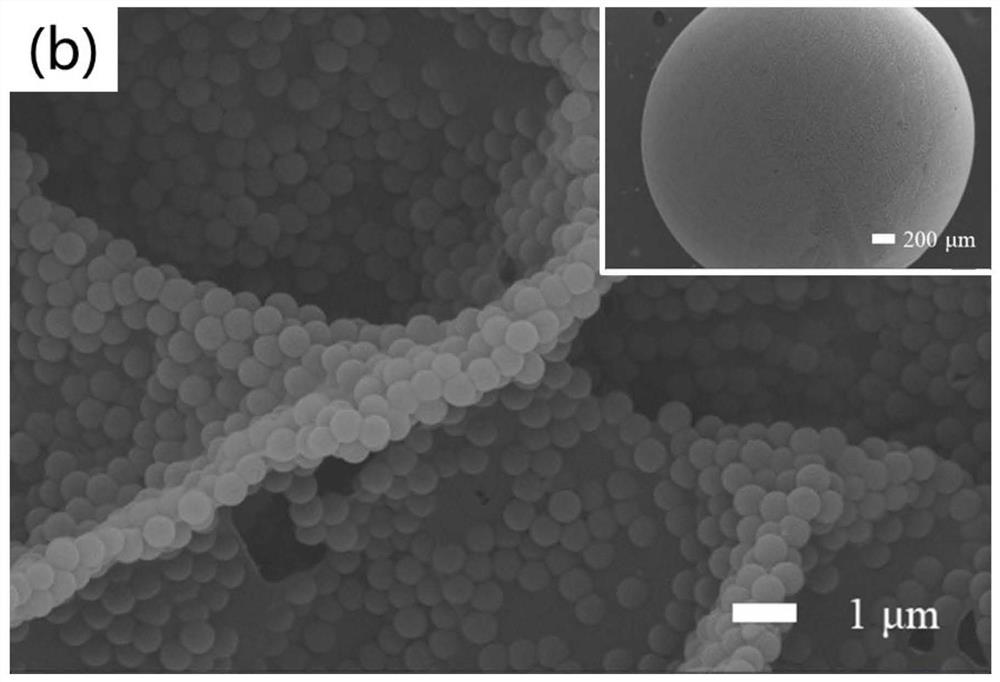

[0053] 3) Prepare a sodium hydroxide solution with a molar concentration of 1 mol / L, put 1 g of the carbonized sample into 300 mL of sodium hydroxide solution, condense and reflux at 80 ° C for 3 hours, and filter the solution after fully reacting, washing and drying to obtain Hollow carbon microspheres;

[0054] 4) configure the hollow carbon microsphere dispersion of 0.5wt% concentration, add dodecyl dimethyl betaine, an...

Embodiment 2

[0059] 1) Prepare a mixed solution of tetraethyl orthosilicate, ethanol, ammonia water, resorcinol, formaldehyde and water, stir at 750rpm at 35°C, and centrifuge the solution after fully reacting for 24 hours, suction filter, wash and dry Obtain carbon / silicon composite microspheres;

[0060] 2) Put carbon / silicon composite microspheres into a tube furnace for carbonization, use an argon atmosphere, heat up to 700°C at a heating rate of 3°C / min, and then hold for 5 hours;

[0061] 3) Prepare a sodium hydroxide solution with a molar concentration of 1 mol / L, put 1 g of the carbonized sample into 300 mL of sodium hydroxide solution, condense and reflux at 90 ° C for 2 hours, and filter the solution after fully reacting, washing and drying to obtain Hollow carbon microspheres;

[0062] 4) configure a chitosan solution with a concentration of 3wt%, and simultaneously configure a dispersion of hollow carbon microspheres with a concentration of 0.2wt%, add dodecyl sulfopropyl beta...

Embodiment 3

[0067] 1) Prepare a mixed solution of tetraethyl orthosilicate, ethanol, ammonia water and water, stir at 500rpm at 10°C for 30 minutes, then add catechol and formaldehyde, keep stirring under the same reaction conditions, and then add catechol and formaldehyde after fully reacting for 18 hours The solution is centrifuged, filtered, washed and dried to obtain carbon / silicon composite microspheres;

[0068] 2) Put carbon / silicon composite microspheres into a tube furnace for carbonization, use an argon atmosphere, heat up to 700°C at a heating rate of 2°C / min, and then keep warm for 2 hours;

[0069] 3) Prepare a potassium hydroxide solution with a molar concentration of 1 mol / L, put 1 g of the carbonized sample into 300 mL of potassium hydroxide solution, condense and reflux at 85°C for 2 hours, and filter the solution after fully reacting, washing and drying to obtain Hollow carbon microspheres;

[0070] 4) Prepare a sodium alginate solution with a concentration of 3wt%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

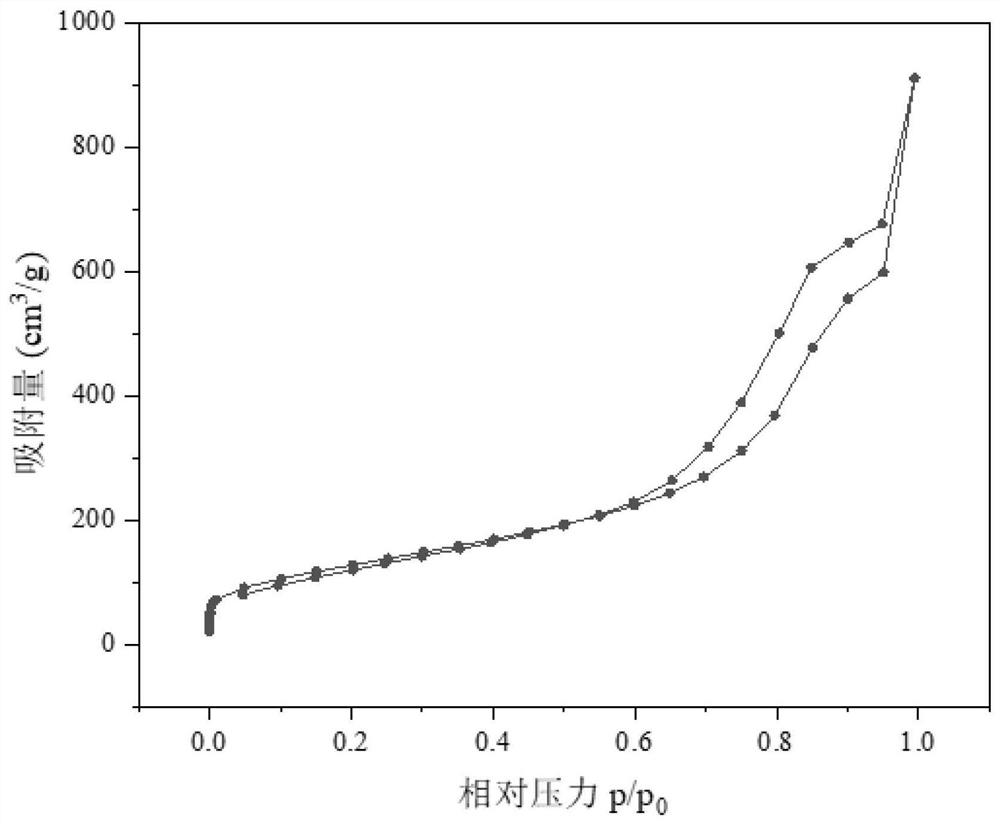

| Specific surface area | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com