Solar heat reflection heat insulation coating and preparation method thereof

A technology of reflective thermal insulation paint and solar heat, applied in the direction of reflection/signal paint, coating, etc., can solve the problems of reducing the thermal insulation performance of the paint, the reflective thermal insulation paint is easily broken, and the thermal conductivity rises, so as to improve the stain resistance. Performance, Interaction Enhancement, Effects of Improved Compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

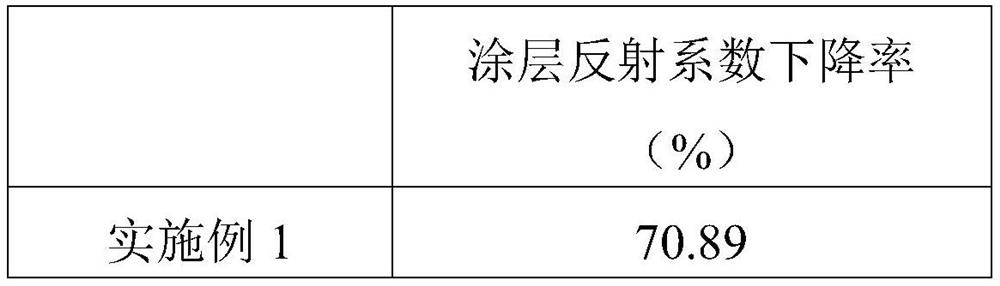

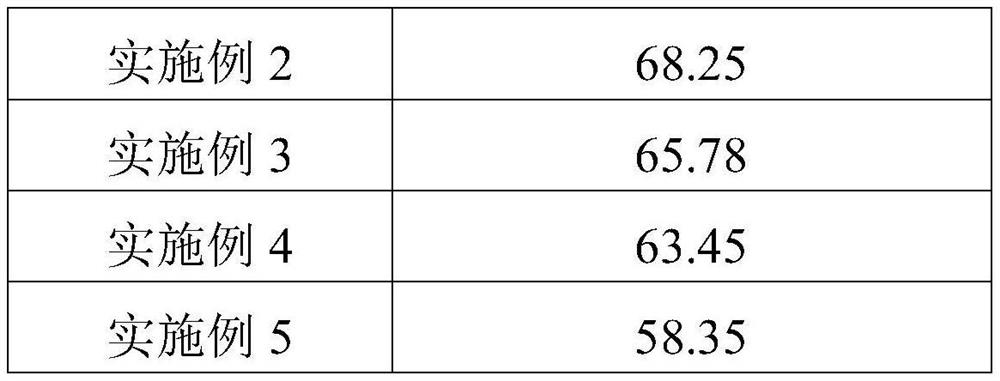

Examples

Embodiment 1

[0055] A preparation method of a solar heat reflective heat insulating coating, comprising the steps of:

[0056] S1 Stir 1 part of sodium polyacrylate, 0.5 part of tributyl phosphate, 0.4 part of tristyrylphenol polyoxyethylene ether, 0.05 part of 30 wt% ammonia water, and 40 parts of water at a speed of 500 r / min for 20 minutes to obtain a solution 1;

[0057] S2 Add 15 parts of hollow glass microspheres and 10 parts of modified rutile titanium dioxide to solution 1, and stir for 10 minutes at a rotating speed of 500 r / min to obtain solution 2;

[0058] S3 adds 50 parts of bonding agent, 0.2 part of propylene glycol butyl ether, 0.3 part of hydroxyethyl cellulose to solution 2 and stirs for 30 minutes at a rotating speed of 600r / min to obtain a solar heat reflective heat-insulating coating; the bonding agent is acrylic acid lotion.

[0059] The preparation method of described modified rutile titanium dioxide is as follows:

Embodiment 2

[0063] A preparation method of a solar heat reflective heat insulating coating, comprising the steps of:

[0064] S1 Stir 1 part of sodium polyacrylate, 0.5 part of tributyl phosphate, 0.4 part of tristyrylphenol polyoxyethylene ether, 0.05 part of 30 wt% ammonia water, and 40 parts of water at a speed of 500 r / min for 20 minutes to obtain a solution 1;

[0065] S2 Add 15 parts of hollow glass microspheres and 10 parts of modified rutile titanium dioxide to solution 1, and stir for 10 minutes at a rotating speed of 500 r / min to obtain solution 2;

[0066] S3 adds 50 parts of bonding agent, 0.2 part of propylene glycol butyl ether, 0.3 part of hydroxyethyl cellulose to solution 2 and stirs for 30 minutes at a rotating speed of 600r / min to obtain a solar heat reflective heat-insulating coating; the bonding agent is two Silica airgel.

[0067] The preparation method of described modified rutile titanium dioxide is as follows:

[0068] 1) Add 20 g of rutile titanium dioxide to a...

Embodiment 3

[0071] A preparation method of a solar heat reflective heat insulating coating, comprising the steps of:

[0072] S1 Stir 1 part of sodium polyacrylate, 0.5 part of tributyl phosphate, 0.4 part of tristyrylphenol polyoxyethylene ether, 0.05 part of 30 wt% ammonia water, and 40 parts of water at a speed of 500 r / min for 20 minutes to obtain a solution 1;

[0073] S2 Add 15 parts of hollow glass microspheres and 10 parts of modified rutile titanium dioxide to solution 1, and stir for 10 minutes at a rotating speed of 500 r / min to obtain solution 2;

[0074] S3 adds 50 parts of bonding agent, 0.2 part of propylene glycol butyl ether, 0.3 part of hydroxyethyl cellulose to the solution 2 and stirs for 30 minutes at a rotating speed of 600r / min to obtain the solar heat reflective heat-insulating coating; the bonding agent is mass Mixture of silica airgel and acrylic emulsion in a ratio of 1:2.

[0075] The preparation method of described modified rutile titanium dioxide is as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com