Potassium ion battery negative electrode material as well as preparation method and application thereof

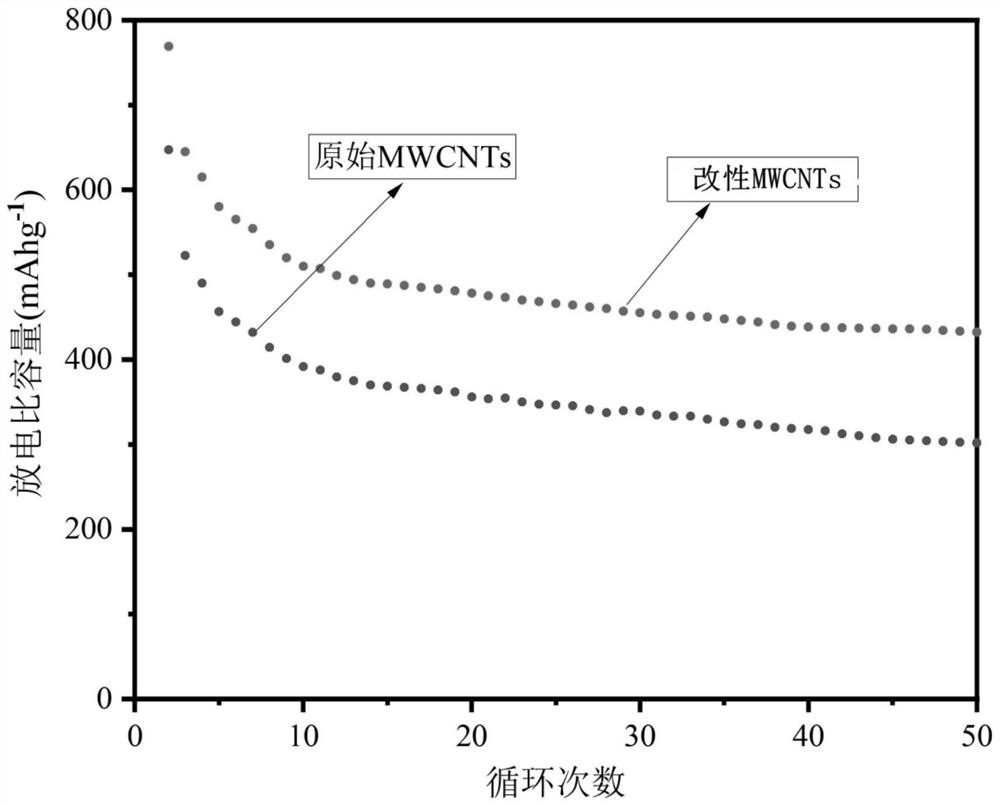

A battery negative electrode and potassium ion technology, applied in the field of electrochemistry, can solve the problems of irreversible capacity loss, restricting the development of potassium storage materials, and destroying the structure of electrode materials, etc., achieving excellent cycle stability, improved electrochemical performance, and increased discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Surface modification treatment:

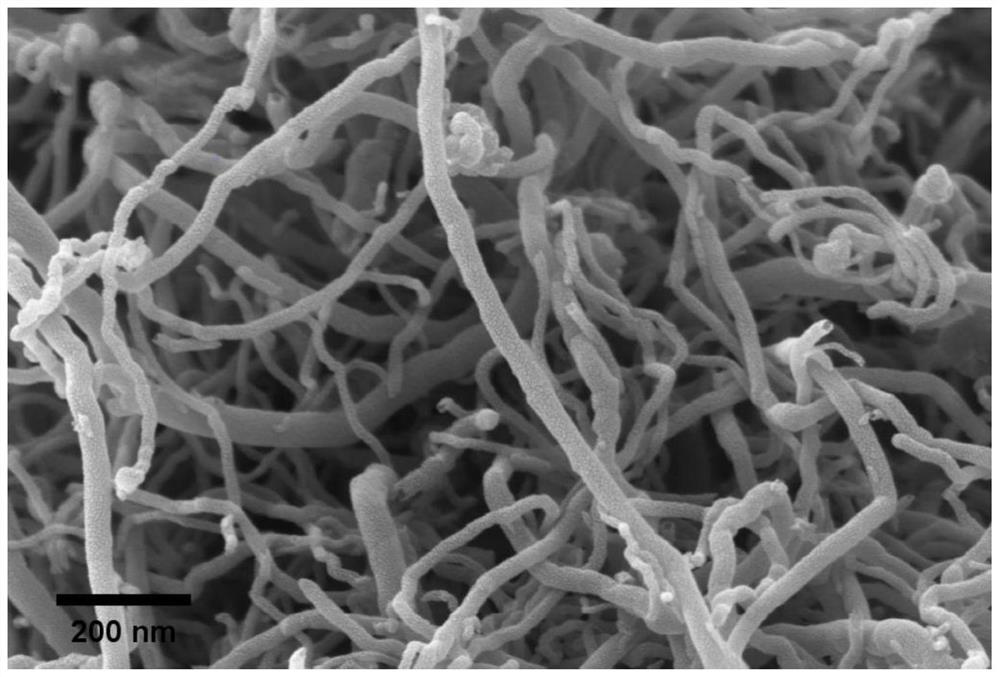

[0025] Put the multi-walled carbon nanotubes into the SAOT YZD08-5C plasma generator, use radio frequency 12MHz to generate plasma, and select high-purity nitrogen as the working gas, the working power is 120w, the working vacuum is 45Pa, and the processing time is 30 minutes. After processing the samples were redistributed and processed again with the previous parameters to ensure uniformity. Finally, modified multi-walled carbon nanotubes are obtained.

[0026] (2) Preparation of anode materials for potassium ion batteries:

[0027] Weigh 80 mg of surface-modified multi-walled carbon nanotube powder, put it into a mortar and grind for 30 min, after grinding evenly, then weigh 10 mg of conductive agent acetylene black and add it into the mortar, and continue grinding for 30 min. The ground mixture was placed in a small stirring pot, and 10 mg of sodium carboxymethylcellulose was added to it. Then the small stirring pot was place...

Embodiment 2

[0030] (1) Surface modification treatment:

[0031] Put the multi-walled carbon nanotubes into the SAOT YZD08-5C plasma generator, use radio frequency 15MHz to generate plasma, and select high-purity nitrogen as the working gas, the working power is 150w, the working vacuum is 80Pa, and the treatment time is 10 minutes. The samples were then redistributed and processed again with the previous parameters to ensure uniformity. Finally, modified multi-walled carbon nanotubes are obtained.

[0032] (2) Preparation of anode materials for potassium ion batteries:

[0033] Weigh 80 mg of surface-modified multi-walled carbon nanotube powder, put it into a mortar and grind for 30 min, after grinding evenly, then weigh 10 mg of conductive agent acetylene black and add it into the mortar, and continue grinding for 30 min. The ground mixture was placed in a small stirring pot, and 10 mg of sodium carboxymethylcellulose was added to it. Then the small stirring pot was placed on a magnet...

Embodiment 3

[0035] (1) Surface modification treatment:

[0036] Put the multi-walled carbon nanotubes into the SAOT YZD08-5C plasma generator, use radio frequency 15MHz to generate plasma, and select high-purity nitrogen as the working gas, the working power is 170w, the working vacuum is 80Pa, and the treatment time is 10 minutes. The samples were then redistributed and processed again with the previous parameters to ensure uniformity. Finally, modified multi-walled carbon nanotubes are obtained.

[0037] (2) Preparation of anode materials for potassium ion batteries:

[0038] Weigh 80 mg of surface-modified multi-walled carbon nanotube powder, put it into a mortar and grind for 30 min, after grinding evenly, then weigh 10 mg of conductive agent acetylene black and add it into the mortar, and continue grinding for 30 min. The ground mixture was placed in a small stirring pot, and 10 mg of sodium carboxymethylcellulose was added to it. Then the small stirring pot was placed on a magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com