A weather-resistant self-cleaning self-layering coating and its preparation method and application

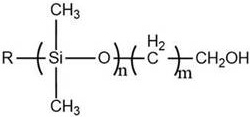

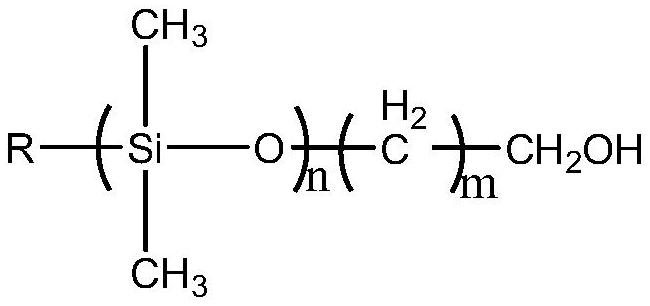

A self-cleaning and self-layering technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of substrate adhesion, poor reactivity, and lack of active hydroxyl groups that affect the cross-linking density of coatings, etc. problems, to achieve the effect of reducing the surface energy of the coating, high mechanical properties, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

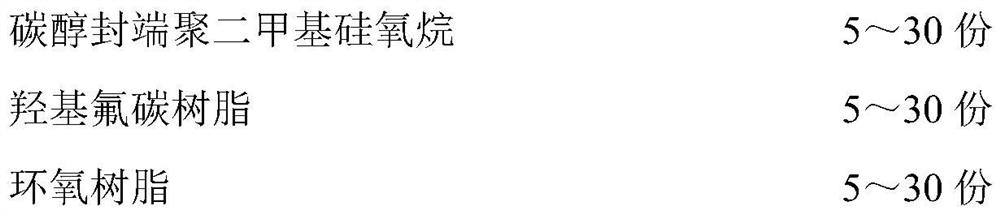

[0043] 80g carbon alcohol-terminated polydimethylsiloxane (R=-CH 3 , n=3, m=3), 120g hydroxyl fluorocarbon resin (hydroxyl value 45mgKOH / g), 80g epoxy resin E20, 80g cyanite CYMEL 1156 curing agent, 0.8g King's NACURE 2500 catalyst and 439.2g xylene in Stir, mix and react at room temperature at 300 r / min for 30 minutes to obtain a weather-resistant self-cleaning and self-layering coating.

Embodiment 2

[0045] 135g carbon alcohol terminated polydimethylsiloxane (R=-(CH 2 ) 6 CH 2 OH, n=15, m=6), 225g hydroxyl fluorocarbon resin (hydroxyl value 60mgKOH / g), 72g epoxy resin E44, 180g cyanite CYMEL 325 curing agent, 4.5g King's NACURE 2107 catalyst and 103.5g propylene glycol methyl Ether acetate and 180 g of ethyl acetate were stirred, mixed and reacted at room temperature at 100 r / min for 60 minutes to obtain a weather-resistant self-cleaning self-layering coating.

Embodiment 3

[0047] 135g carbon alcohol terminated polydimethylsiloxane (R=-(CH 2 ) 19 CH 3 , n=50, m=12), 270g hydroxyl fluorocarbon resin (hydroxyl value 30mgKOH / g), 45g epoxy resin E51, 135g cyanate CYMELXW3106 curing agent, 4.5g King's NACURE 5414 catalyst and 310.5g butyl acetate in Stir, mix and react for 10 minutes at room temperature at a speed of 500 r / min to obtain a weather-resistant self-cleaning self-layering coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com