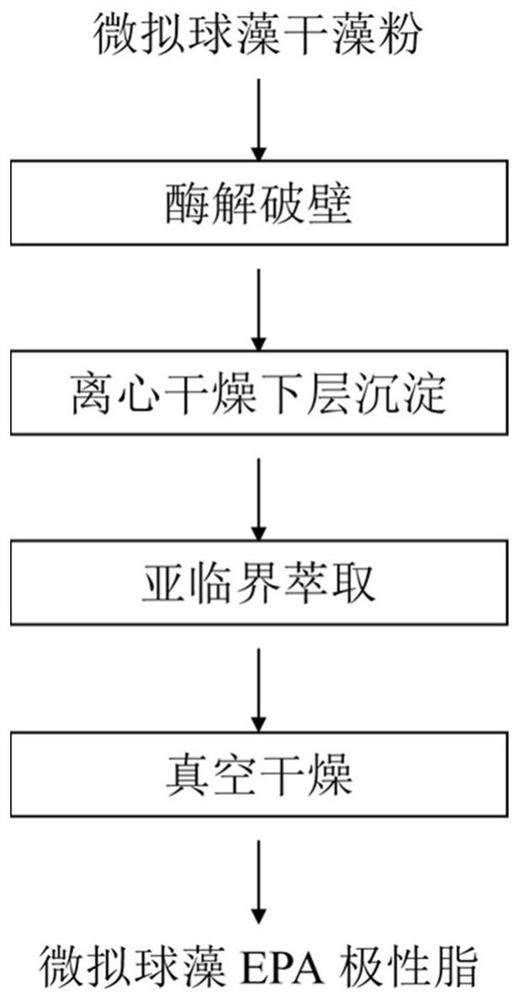

Method for extracting nannochloropsis oculata EPA polar lipid under assistance of enzyme treatment

A Nannochloropsis, auxiliary extraction technology, applied in the direction of fat production, fat oil/fat production, fat oil/fat refining, etc., can solve the problem of not being able to directly obtain pure EPA polar lipids and increase the extraction rate of Nannochloropsis polar lipids And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

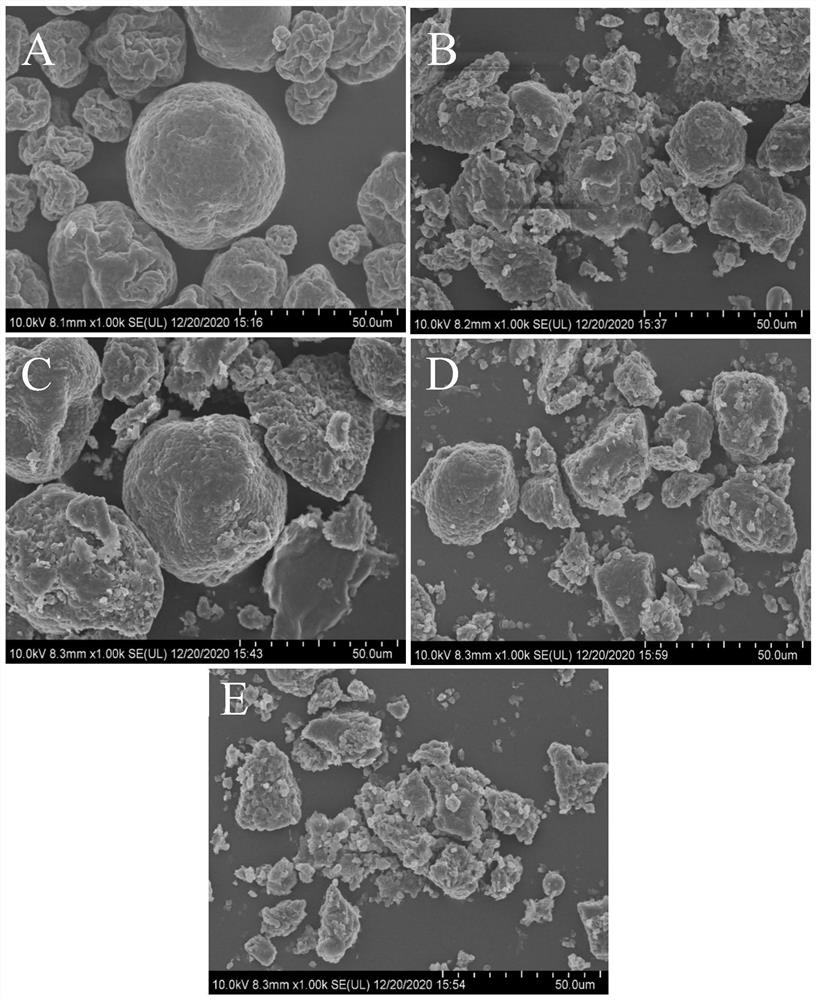

Embodiment 1

[0056] Mix Nannochloropsis with citric acid-sodium citrate buffer solution with pH=5 according to the ratio of solid to liquid 1:5, and add laccase so that the enzyme activity of laccase in the system is 0.24U / ml. Enzymolysis was carried out for 3 hours to obtain a Nannochloropsis enzymolysis suspension; the Nannochloropsis suspension was centrifuged at a centrifugation speed of 4000r / min and a centrifugation time of 20 minutes, and the supernatant was removed after centrifugation. Take the lower layer of sediment and dry at 65°C for 16 hours to obtain Nannochloropsis enzymatically hydrolyzed broken-wall algae powder; use Nannochloropsis enzymolyzed broken-walled algae powder according to the ratio of solid to liquid 1:15 and the concentration of 90 % ethanol is mixed, placed in a reaction kettle and sealed with nitrogen gas, heated to 70°C, extracted for 70 minutes, and extracted 8 times to obtain the Nannochloropsis polar lipid extract; extract the Nannochloropsis polar lipid...

Embodiment 2

[0058] Mix Nannochloropsis with citric acid-sodium citrate buffer solution with pH=5 according to the ratio of solid to liquid 1:5, and add laccase-cellulase complex enzyme to make the enzymatic activity of laccase and cellulase in the system 0.1U / ml and 100U / ml, respectively, and enzymolysis at 50°C for 3 hours to obtain a suspension of Nannochloropsis enzymolysis; centrifuge the suspension of Nannochloropsis at 4000r / min, Centrifuge at a centrifugation time of 20 minutes, remove the supernatant after centrifugation, and remove the lower layer of sediment at a drying temperature of 65°C for a drying time of 16 hours to obtain Nannochloropsis enzymatically broken wall algae powder; enzymatically hydrolyze Nannochloropsis The broken algae powder is mixed with 90% ethanol according to the ratio of material to liquid 1:15, placed in the reaction kettle and sealed with nitrogen gas, heated to 70°C, extracted for 70 minutes, and extracted 8 times to obtain Nannochloropsis Polar lip...

Embodiment 3

[0060] Mix Nannochloropsis with citric acid-sodium citrate buffer solution with pH=5 according to the ratio of solid to liquid 1:5, and add laccase-cellulase complex enzyme to make the enzymatic activity of laccase and cellulase in the system 1U / ml and 500U / ml, respectively, and enzymolysis at 50°C for 3 hours to obtain a Nannochloropsis enzymolysis suspension; centrifuge the Nannochloropsis hydrolysis suspension at a centrifugal speed of 4000r / min Centrifuge under the condition of 20 minutes, remove the supernatant after centrifugation, take the lower layer and precipitate at a drying temperature of 65°C, and dry for 16 hours to obtain Nannochloropsis enzymatically broken wall algae powder; The wall algae powder is mixed with 90% ethanol according to the ratio of solid to liquid at 1:15, placed in the reaction kettle and sealed with nitrogen gas, heated to 70°C, extracted for 70 minutes, and extracted 8 times to obtain Nannochloropsis. Lipid extract; Centrifuge the Nannochlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com