High ozone catalytic activity diamond electrode and preparation method and application thereof

A diamond electrode and catalytic activity technology, applied in the field of electrochemistry, can solve the problems of complex medical wastewater components, and achieve the effects of improving electrolysis efficiency, strong tolerance, and increasing capillary effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

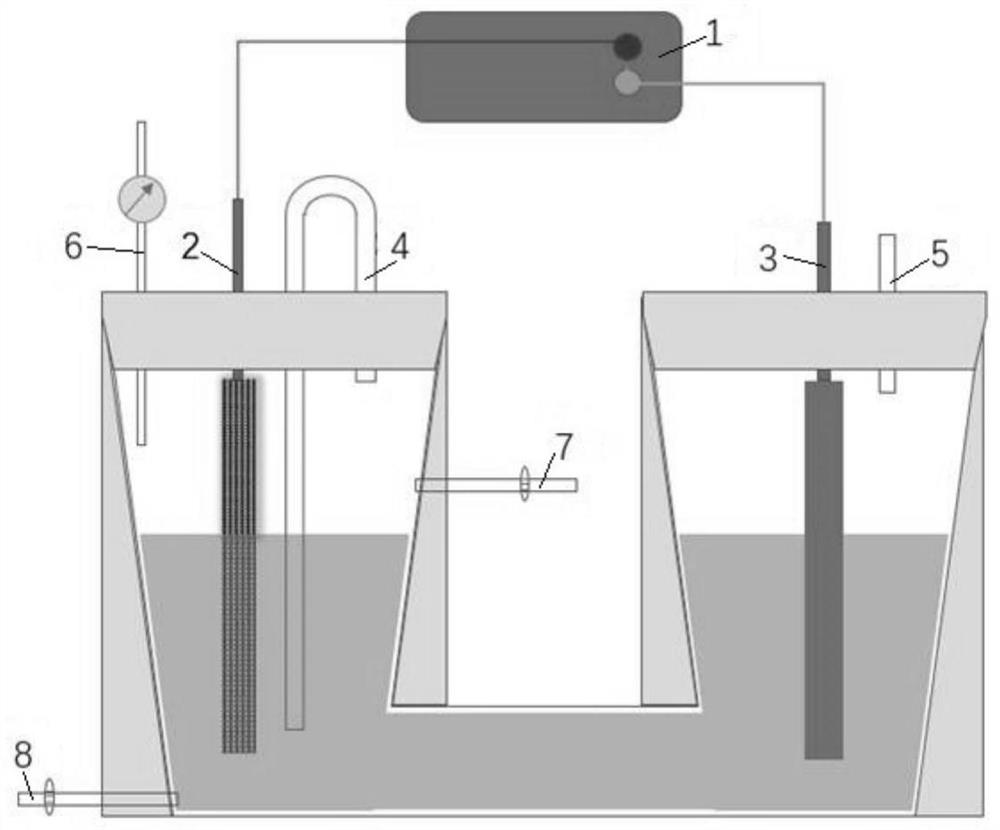

Image

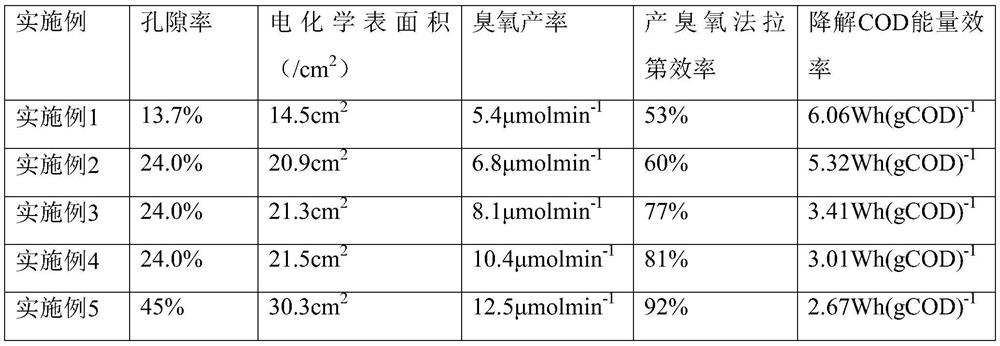

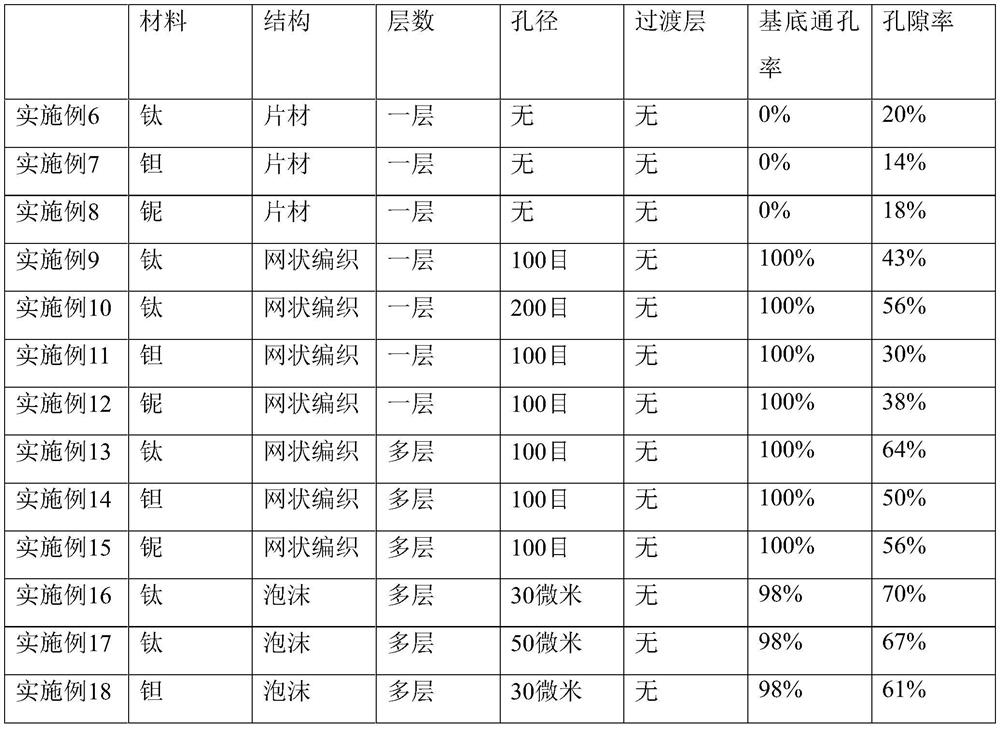

Examples

Embodiment 1

[0054] Step 1: Substrate pretreatment. Put a double-layer or triple-layer titanium mesh with a size of 3.5cm×7cm into 96mL (deionized water 90mL, concentrated sulfuric acid 6mL) of dilute sulfuric acid solution, and ultrasonically polish the surface for 30min. Then the titanium mesh was taken out, cleaned by ultrasonication in acetone and ethanol respectively for 5 minutes, the cleaned substrate was placed in diamond suspension and ultrasonicated for 30 minutes, and then blown dry with nitrogen at room temperature after taking it out.

[0055] Step 2: depositing boron doped diamond. Place the titanium mesh base on the abutment, keep the titanium mesh base in the middle of the hot wire and parallel to the hot wire, and the distance between the hot wire and the surface of the substrate is 20 mm. The pressure in the furnace is pumped down to below 0.1Pa, and then the reaction mixture gas is introduced. The gas introduced includes methane, hydrogen, and trimethylborane. Methane i...

Embodiment 2

[0060] Step 1: Substrate pretreatment. Put a double-layer or triple-layer titanium mesh with a size of 3.5cm×7cm into 96mL (deionized water 90mL, concentrated sulfuric acid 6mL) of dilute sulfuric acid solution, and ultrasonically polish the surface for 30min. Then the titanium mesh was taken out, cleaned by ultrasonication in acetone and ethanol respectively for 5 minutes, the cleaned substrate was placed in diamond suspension and ultrasonicated for 30 minutes, and then blown dry with nitrogen at room temperature after taking it out.

[0061] Step 2: depositing boron doped diamond. Place the titanium mesh base on the abutment, keep the titanium mesh base in the middle of the hot wire and parallel to the hot wire, and the distance between the hot wire and the surface of the substrate is 20 mm. The pressure in the furnace is pumped down to below 0.1Pa, and then the reaction mixture gas is introduced. The gas introduced includes methane, hydrogen, and trimethylborane. Methane i...

Embodiment 3

[0067] Step 1: Substrate pretreatment. Put a double-layer or triple-layer titanium mesh with a size of 3.5cm×7cm into 96mL (deionized water 90mL, concentrated sulfuric acid 6mL) of dilute sulfuric acid solution, and ultrasonically polish the surface for 30min. Then the titanium mesh was taken out, cleaned by ultrasonication in acetone and ethanol for 5 minutes respectively, the cleaned substrate was put into diamond suspension and ultrasonicated for 30 minutes, and then blown dry with nitrogen at room temperature after taking it out.

[0068] Step 2: depositing boron doped diamond. Place the titanium mesh base on the abutment, keep the titanium mesh base in the middle of the hot wire and parallel to the hot wire, and the distance between the hot wire and the surface of the substrate is 20mm. The pressure in the furnace is pumped down to below 0.1Pa, and then the reaction mixture gas is introduced. The gas introduced includes methane, hydrogen, and trimethylborane. Methane is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com