Method and device for multi-wavelength ultraviolet-electrochemical segmented treatment of wastewater

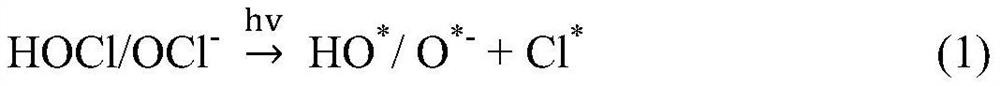

A technology for wastewater treatment and electrochemistry, applied in the field of water treatment, can solve problems such as the application and promotion of pollutant removal, HClO instability, application restrictions, etc., to avoid high-current operation mode, good selectivity, and anti-pollution ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

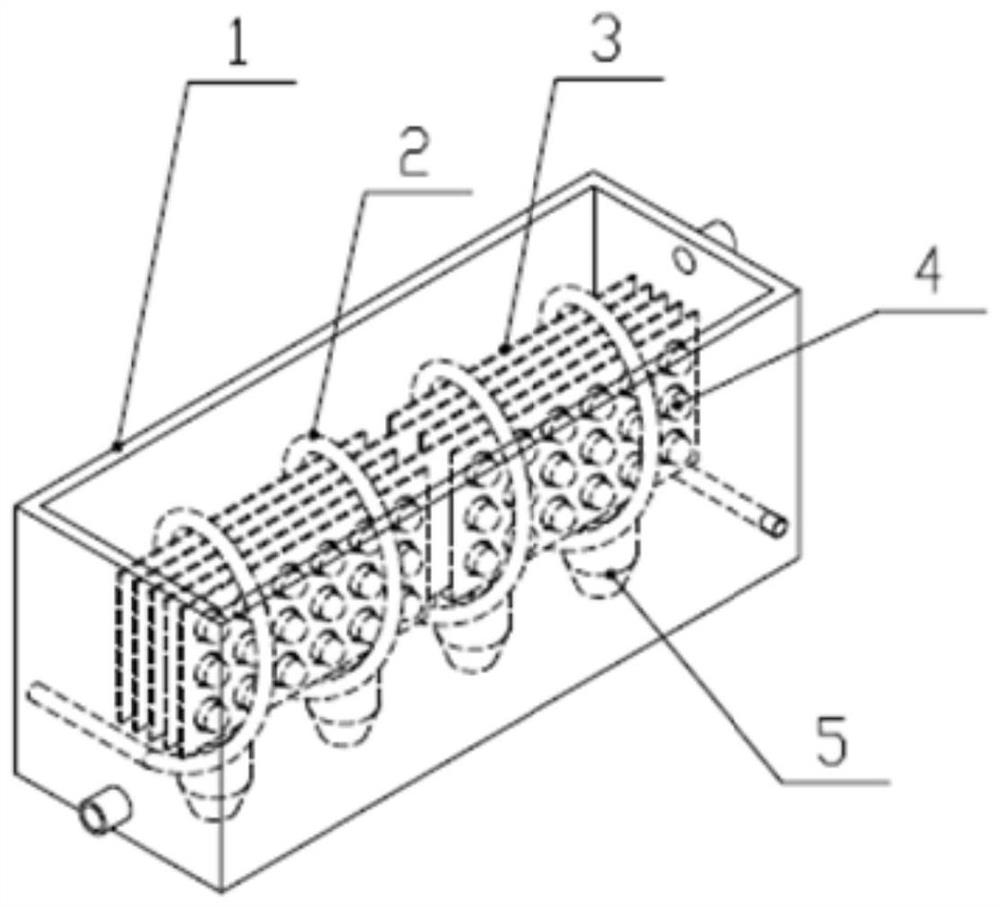

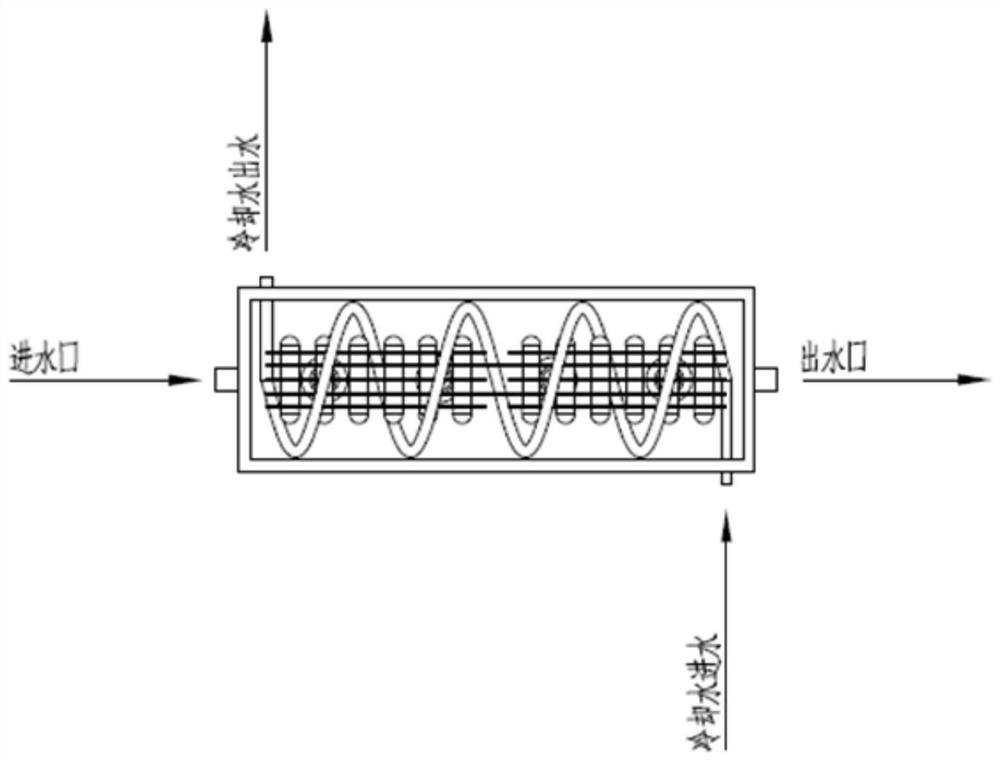

[0046] The initial chloride ion concentration in the water sample to be treated was adjusted to 150mg / L. Add the water sample to be treated into the electrolytic cell of the present invention, connect the electrodes to the DC power supply correspondingly, turn on the LED ultraviolet lamp at the same time, turn on the ultrasonic generator 5 at the bottom of the electrolytic cell 1, and form a disturbance to the wastewater in the electrolytic cell 1 , and to prevent scaling on the surface of the bipolar electrode 3, the current density is 300mA / cm 2 ,

[0047] The treatment time is about 8 minutes, and the removal rate of refractory organic matter in water can reach more than 90%.

Embodiment 2

[0049] The initial chloride ion concentration in the water sample to be treated was adjusted to 120mg / L. Add the water sample to be treated into the electrolytic cell of the present invention, connect the electrodes to the DC power supply correspondingly, turn on the LED ultraviolet lamp at the same time, turn on the ultrasonic generator 5 at the bottom of the electrolytic cell 1, and form a disturbance to the wastewater in the electrolytic cell 1 , and prevent scaling on the surface of bipolar electrode 3, the current density is 320mA / cm 2 ,

[0050] The treatment time is about 10 minutes, and the removal rate of refractory organic matter in water can reach more than 90%.

Embodiment 3

[0052] The initial chloride ion concentration in the water sample to be treated was adjusted to 120mg / L. Add the water sample to be treated into the electrolytic cell of the present invention, connect the electrodes to the DC power supply correspondingly, turn on the LED ultraviolet lamp at the same time, turn on the ultrasonic generator 5 at the bottom of the electrolytic cell 1, and form a disturbance to the wastewater in the electrolytic cell 1 , and prevent scaling on the surface of the bipolar electrode 3, the current density is 330mA / cm 2 ,

[0053] The treatment time is about 15 minutes, and the removal rate of refractory organic matter in water can reach more than 90%.

[0054] The multi-wavelength ultraviolet-electrochemical stepwise wastewater treatment method described in the present invention can be used to treat various refractory industrial chemical wastewater, pesticide residues and medical wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com