Preparation method of composite laser crystal

A composite laser crystal and seed crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of large composite interface, large loss, poor composite crystal interface bonding strength, etc., and achieve high interface bonding strength , good optical uniformity and optical quality, high quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the composite laser crystal provided by the embodiment of the present invention is particularly suitable for preparing a composite laser crystal with a large interface composite structure, for example, a composite laser crystal with a planar waveguide structure, a composite laser crystal with a ring waveguide structure, and a composite laser crystal with a surface gain structure. Wait.

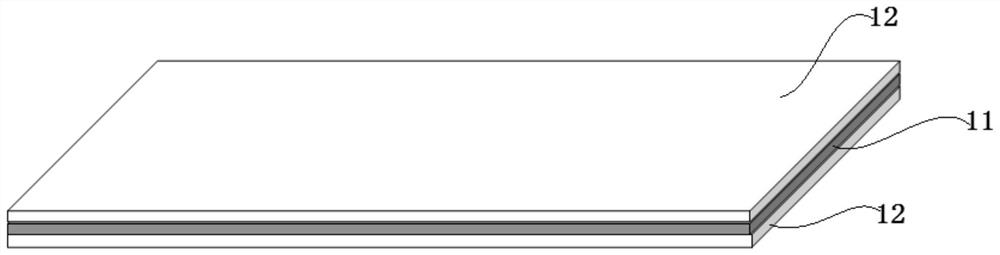

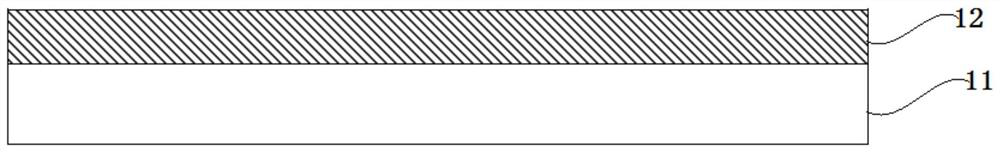

[0049] figure 1 A composite laser crystal with a planar waveguide structure is exemplified, which includes: two symmetrically arranged functional support layers 12 , and a gain medium layer 11 interposed between the two functional support layers 12 by bonding. Exemplarily, the functional support layer 12 is an undoped yttrium aluminum garnet crystal, and the gain medium layer 11 is a doped yttrium aluminum garnet crystal.

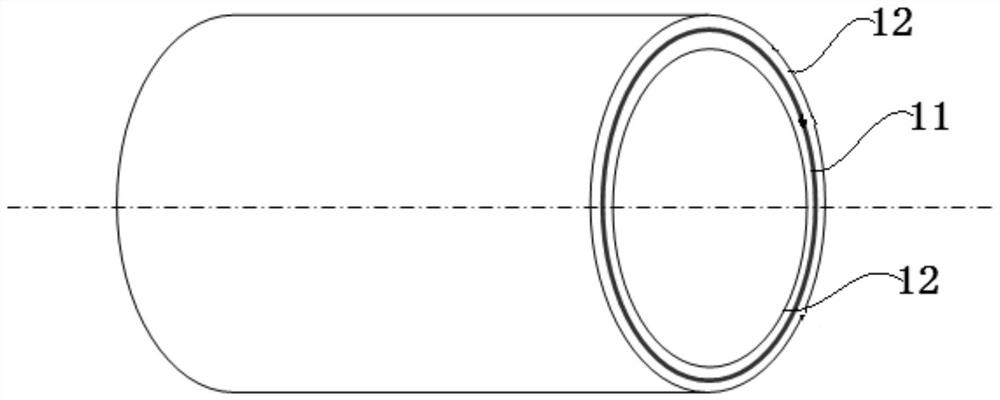

[0050] figure 2 A compound laser crystal with a ring waveguide structure is illustrated, which includes: an inner functional support lay...

Embodiment 1

[0105] Example 1: Preparation of Nd:YAG planar waveguide composite crystal

[0106] In the material selection sector of the Nd:YAG crystal blank with a doping concentration of 0.2at% grown by the pulling method, a Nd:YAG crystal slab with a width of 22mm, a thickness of 1mm, and a length of 85mm was selected, and the surface was finely ground and processed into 0.2mm×22mm×85mm seed crystal.

[0107] After cleaning the surface of the seed crystal, soak it with potassium dichromate washing solution for no less than 12 hours, and then wash it with H 2 SO 4 and H 2 o 2 It was prepared in a washing solution prepared at a volume ratio of 1:1, washed at a temperature of 95°C for 5 minutes, and then ultrasonically cleaned in deionized water for 30 minutes.

[0108] Prepare KOH to 3mol·L -1 The solution was used as a mineralizer solution, and 20 g of undoped YAG polycrystalline powder with a purity of 4N was used as a bonding material.

[0109] Put the bonding material in the hig...

Embodiment 2

[0112] Embodiment 2: Preparation of Yb:YAG planar waveguide composite crystal

[0113] In the material selection sector of the Yb:YAG crystal blank with a doping concentration of 5.0at% grown by the pulling method, a Yb:YAG crystal slab with a width of 32mm, a thickness of 1mm, and a length of 135mm was selected, and the surface was finely ground and processed into A seed crystal of 0.1mm×32mm×135mm.

[0114] After cleaning the surface of the seed crystal, soak it with potassium dichromate washing solution for no less than 12 hours, and then wash it with H 2 SO 4 and H 2 o 2 It was prepared in a washing solution prepared at a volume ratio of 1:1, washed at a temperature of 100°C for 5 minutes, and then ultrasonically cleaned in deionized water for 30 minutes.

[0115] At the same time, prepare a concentration of 3mol L -1 of NaOH and a concentration of 1mol L -1 The mixed solution of ammonia water was set aside, and 50 g of undoped YAG polycrystalline powder with a purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com