Carbon felt-loaded cerium-doped alpha-FeOOH nanosheet array electrode and preparation method and application thereof

A nanosheet array, cerium doping technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of low activity, refractory degradation, and small organic removal capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A preparation method of a carbon felt supported cerium-doped α-FeOOH nanosheet array electrode, comprising the following steps:

[0049] 1) Add FeSO to ultrapure water 4 ·7H 2 O and CeCl 3 ·7H 2 O and ultrasonically disperse for 5-15min to form 0-1.92mM Fe 2+ , 0-1.92mM Ce 3+ mixed solution;

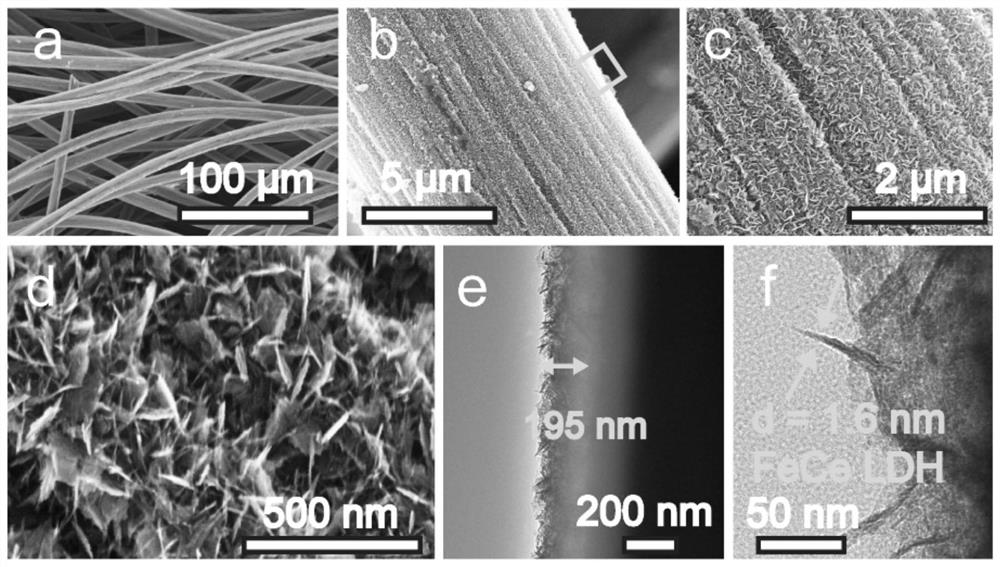

[0050] 2) Add glycerin and conductive carbon felt, and conduct a hydrothermal reaction at 100-150°C for 20-28h. After the reaction product is cooled to room temperature, wash it with ethanol and ultrapure water for 3-5 times, and heat it at 60-80°C Drying for 10-15 hours under the hood can obtain a uniformly dispersed nanosheet array electrode.

[0051] Wherein, the volume ratio of glycerol to the mixed solution is 3:(10-15), and the loading amount of the active material containing iron and cerium on the obtained nanosheet array electrode is 1-3 mg, and the loading thickness is 180-200 nm.

[0052] The above-mentioned carbon felt-loaded cerium-doped α-FeOOH nanosheet array ...

Embodiment 1

[0064] (1) a carbon felt supported cerium-doped α-FeOOH nanosheet array electrode (Fe:Ce=6:0), its preparation method may further comprise the steps:

[0065] S1, add FeSO to 130mL ultrapure water 4 ·7H 2 O and ultrasonically dispersed for 10 min to form 1.92 mM Fe 2+ aqueous solution;

[0066] S2, add 30mL of glycerin, mix well, then sonicate for 20min, then transfer to a 250mL reactor, and immerse three pieces of 2cm×2cm CF in it;

[0067] S3, seal the reactor and perform hydrothermal reaction at 120°C for 24h, after cooling to room temperature, take out the modified CF, wash with ethanol and ultrapure water for 3 times, and then dry overnight at 60°C in an oven, that is The above-mentioned carbon felt-supported cerium-doped α-FeOOH nanosheet array electrode (Fe:Ce=6:0) was obtained.

[0068] (2) a carbon felt supported cerium-doped α-FeOOH nanosheet array electrode (Fe:Ce=4:2), its preparation method may further comprise the steps:

[0069] S1, add FeSO to 130mL ultrap...

Embodiment 2

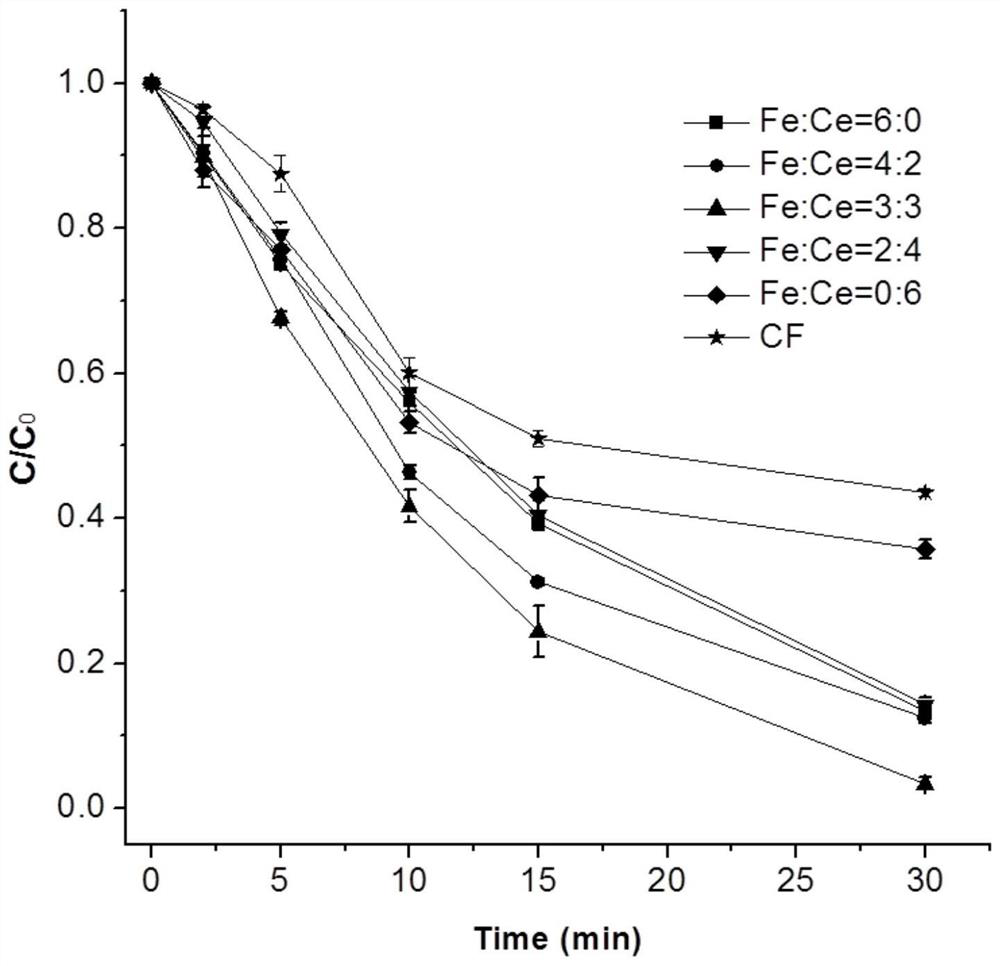

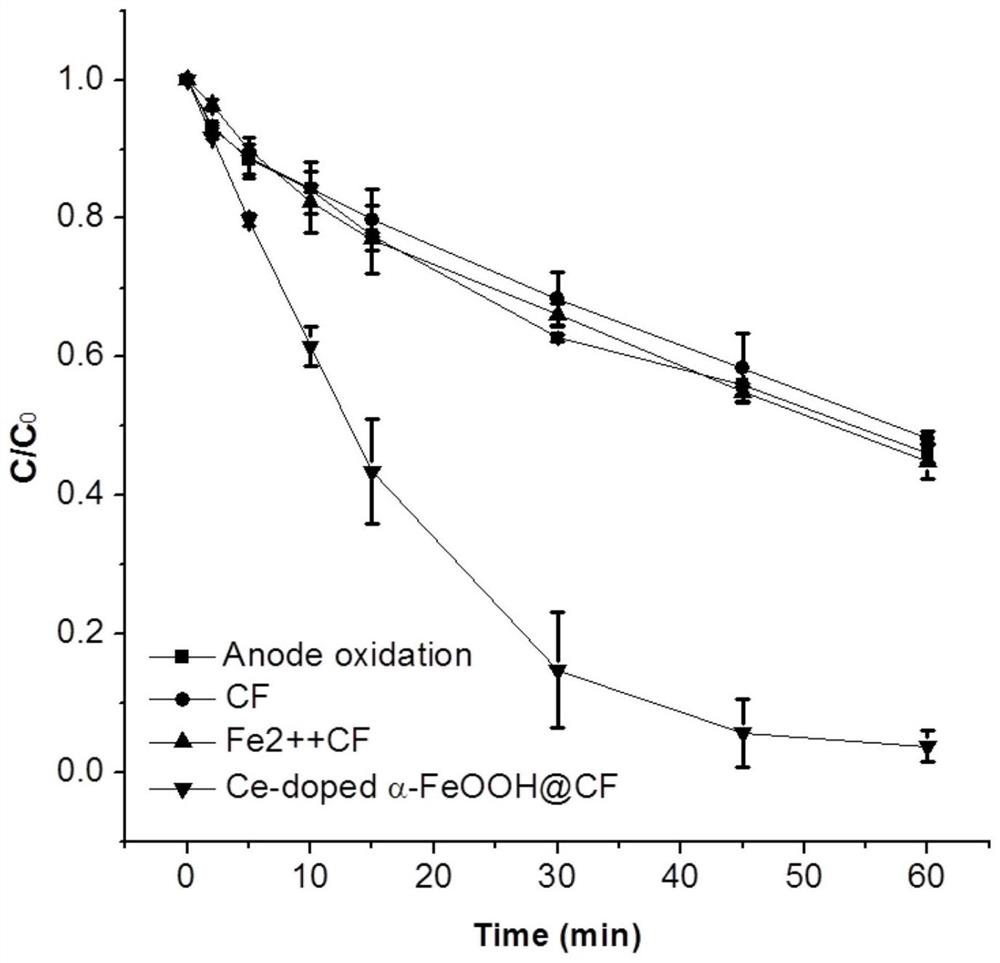

[0086] This example is used to explore the effect of electrode materials with different Fe:Ce ratios on the removal effect of chloramphenicol in simulated wastewater.

[0087] The reactor used is a cylindrical glass reactor with an inner diameter of 80mm and a height of 100mm, and the volume of the electrolyte is 100mL.

[0088] The specific reaction conditions are: use a programmable DC power supply as the current output device, adopt a constant current output mode, and set the reaction current to 30mA; use BDD (2cm×2cm) as the anode, and use the carbon felt CF prepared in Example 1 as the load The cerium-doped α-FeOOH nanosheet array electrode (2cm×2cm) was used as the cathode, and the distance between the two electrodes was adjusted to 1cm; in the aeration system, the aeration rate of high-purity oxygen was controlled at 0.2L min by a flow regulator -1 , and pre-exposed oxygen for 10 minutes before the start of the reaction to make the system reach oxygen saturation; the wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com