Composite electromagnetic shielding film and preparation method thereof

A composite electromagnetic and film technology, applied in the field of materials, can solve the problems of high density of metal materials, electromagnetic shielding performance to be improved, incompetence of corrosion resistance and flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides an MXene / bacterial cellulose composite electromagnetic shielding film and a preparation method thereof. It is characterized in that the method comprises the following steps: 1) preparation of bacterial cellulose fiber homogenate; 2) preparation of MXene dispersion liquid; 3) bacterial cellulose fiber homogenate and MXene dispersion liquid alternate suction filtration to form a film.

[0046] In step 1, the impurities in the bacterial cellulose raw material are removed by pretreatment of the bacterial cellulose wet gel. There are impurities such as protein, carbonate and other organic matter of some bacterial remains in the raw material (bacterial cellulose wet gel) used in the present invention, therefore need pretreatment to remove these impurities, improve the purity of bacterial cellulose, be beneficial to bacterial fiber The mechanical properties of the thin film are improved. Among them, alkali solution treatment is to remove impurities such...

Embodiment 1

[0052] (1) Preparation of bacterial cellulose homogenate:

[0053] First carry out the pretreatment of raw material bacterial cellulose wet gel:

[0054] 1.1 Cut the raw material bacterial cellulose wet gel block into small pieces of 5cm*3cm;

[0055] 1.2 Prepare 1.94wt.% NaOH solution, immerse the bacterial cellulose wet gel in the above NaOH solution, stir at 100°C for 2 hours, then sonicate for 1 hour, and then rinse;

[0056] 1.3 Prepare a 1.045wt.% NaOH solution, immerse the bacterial cellulose wet gel treated in step 1.2 in the NaOH solution of this concentration, stir at 100°C for 2 hours, then sonicate for 1 hour, and then rinse;

[0057] 1.4 Submerge the bacterial cellulose wet gel treated in step 1.3 in a 1.045wt.% NaOH solution, stir at 100°C for 24 hours, then ultrasonicate for 1 hour, and rinse until the bacterial cellulose wet gel leachate is neutral;

[0058] 1.5 Prepare 1.5wt.% acetic acid solution, immerse the bacterial cellulose wet gel treated in step 1.4 ...

Embodiment 2

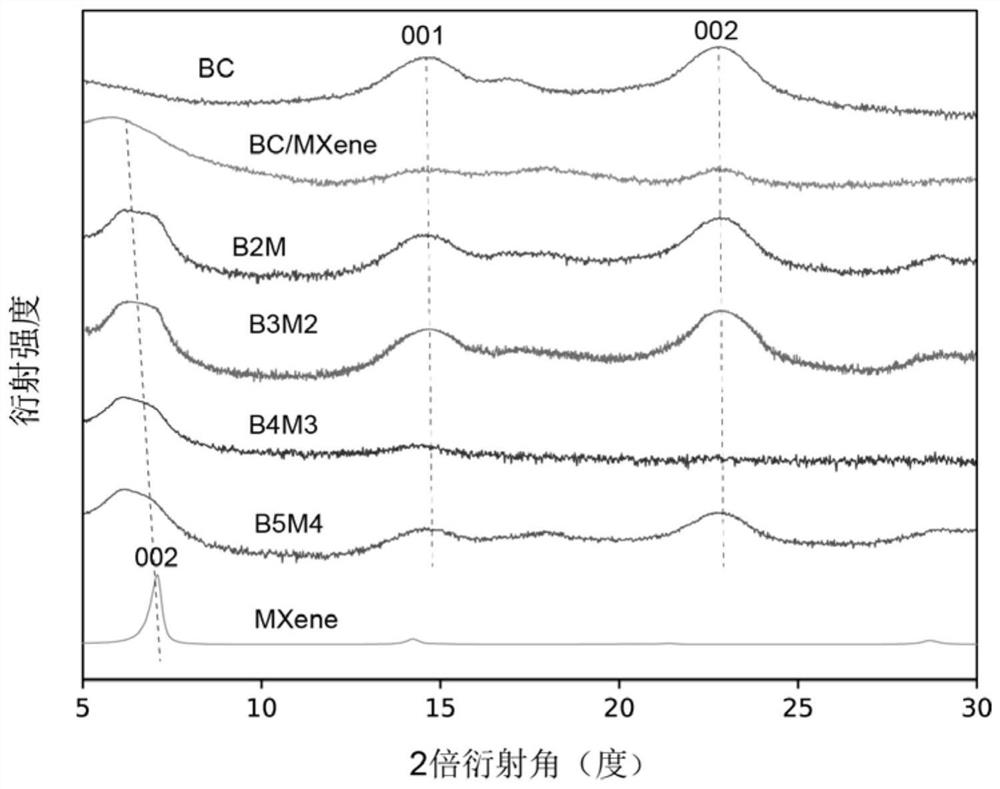

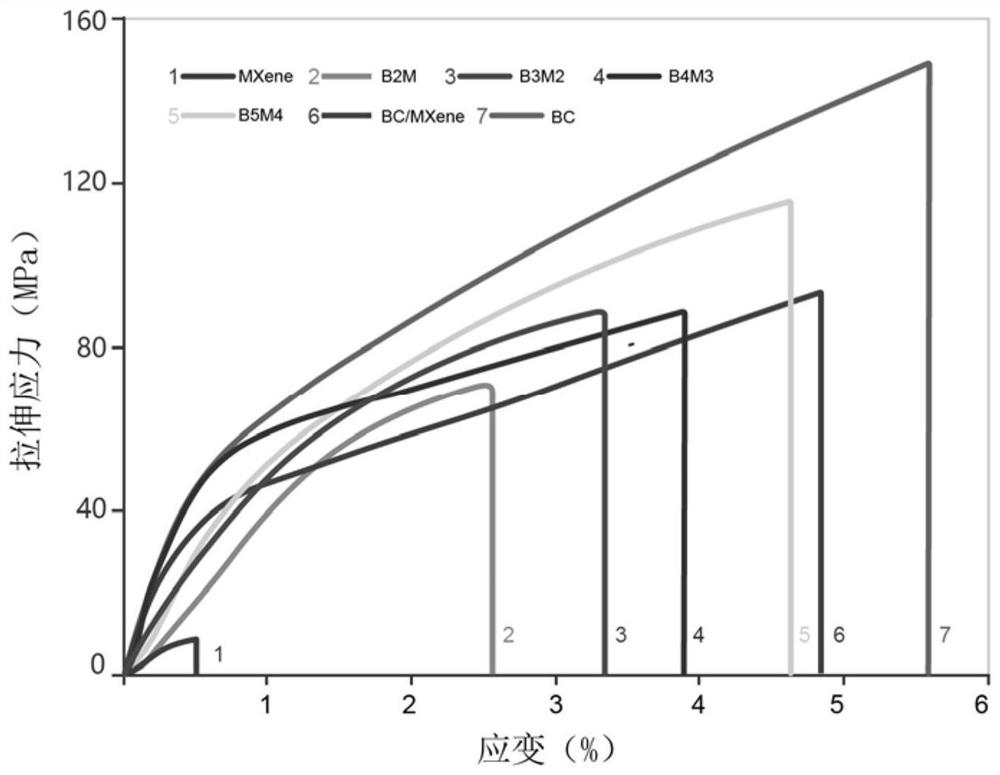

[0070] A method similar to that of Example 1 was used to prepare a composite electromagnetic shielding film, wherein, in step (3) of this example, the solutions added during suction filtration were: 3.33 g of bacterial cellulose homogenate, 5.56 mL of MXene dispersion, and 5.56 mL of bacterial cellulose Vegetable homogenate 3.33g, MXene dispersion 5.56mL, bacterial cellulose homogenate 3.33g. The MXene / bacterial cellulose composite film was prepared, which was designated as sample number B3M2. The total thickness of the composite film is 129.8 μm, in which the average thickness of the MXene film layer is 32.8 μm per layer, and the average thickness of the bacterial cellulose film layer is 21.4 μm per layer.

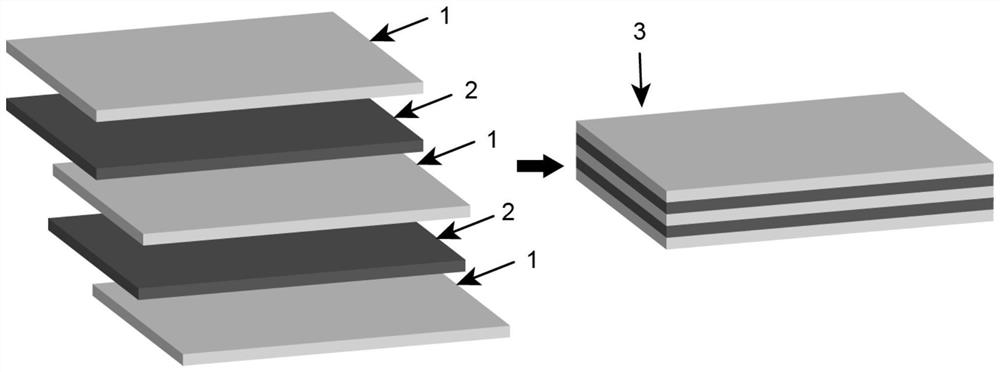

[0071] Such as figure 1 As shown, the structure of the MXene / bacterial cellulose composite electromagnetic shielding film 3 prepared according to Example 2 is a sandwich structure of bacterial cellulose and MXene, wherein the bacterial cellulose film layer is marked as 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com