Adhesive resin for anti-ultraviolet aging type steel wire mesh framework polyethylene composite pipe

A polyethylene composite pipe, anti-ultraviolet aging technology, applied in the field of adhesive resin, can solve problems such as loss of use value, hidden dangers in safe production, and poor appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

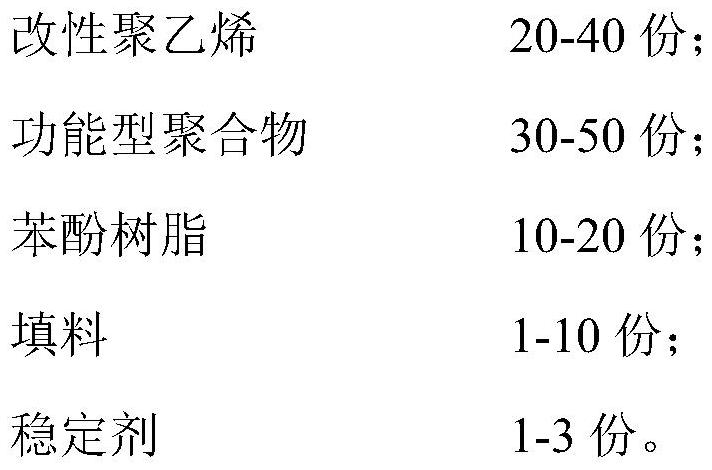

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of above-mentioned bonding resin comprises the steps:

[0031] Step 1, weighing the modified polyethylene, functional polymer, phenol resin, filler and stabilizer according to the parts by mass, adding all the components into a high-speed mixer, and mixing evenly to obtain the material;

[0032] Step 2, adding materials into a twin-screw extruder to extrude strands, cooling the strands through a circulating water tank to room temperature, drying the cooled strands with a blower, and adding them to a pelletizer for granulation.

[0033] In a preferred embodiment of the present invention, the temperature of each temperature zone of the twin-screw extruder extruding the strand is 190-230°C.

Embodiment 1

[0036] This embodiment provides an anti-ultraviolet aging type steel mesh skeleton polyethylene composite pipe adhesive resin, which contains the following components in parts by mass:

[0037]

[0038] Among them, the density of maleic anhydride modified linear low density polyethylene is 0.935g / cm 3 , the melt index is 3.0g / 10min (190 ℃, under the pressure of 2.16kg), the grafting rate of maleic anhydride is 1.1%; in the ethylene-acrylic acid copolymer, the content of acrylic acid is 15%, and the melt index is 4.0g / 10min (190°C, under a pressure of 2.16kg); the stabilizer is an anti-ultraviolet agent and an anti-aging agent, and the mass ratio is 1:1.

[0039] The preparation method of above-mentioned bonding resin comprises the steps:

[0040] Step 1, weighing each component according to the number of parts by mass, adding all the components into a high-speed mixer, and mixing evenly to obtain a material;

[0041] Step 2: Put the materials into the twin-screw extruder ...

Embodiment 2

[0043] This embodiment provides an anti-ultraviolet aging type steel mesh skeleton polyethylene composite pipe adhesive resin, which contains the following components in parts by mass:

[0044]

[0045]

[0046] Among them, the density of maleic anhydride modified linear low density polyethylene is 0.935g / cm 3 , the melt index is 2.0g / 10min (190 ℃, under 2.16kg pressure), the graft rate of maleic anhydride is 1.0%; In the ethylene-vinyl acetate copolymer, the content of vinyl acetate is 18%, and the melt index is 6.0g / 10min (190°C, under a pressure of 2.16kg); the stabilizer is an anti-ultraviolet agent and an anti-aging agent, and the mass ratio is 1:1.

[0047] The preparation method of above-mentioned bonding resin comprises the steps:

[0048] Step 1, weighing each component according to the number of parts by mass, adding all the components into a high-speed mixer, and mixing evenly to obtain a material;

[0049] Step 2: Put the materials into the twin-screw extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com