Formaldehyde-free adhesive, method for preparing composite artificial board by using formaldehyde-free adhesive and prepared composite artificial board

A technology for adhesives and wood-based panels, which is used in the joining of wooden veneers, adhesive types, polyurea/polyurethane adhesives, etc. problem, to achieve the effect of high bonding strength and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

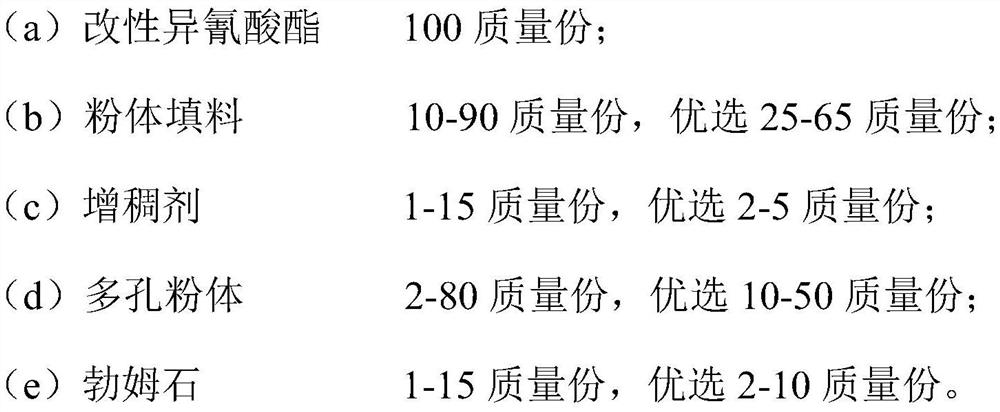

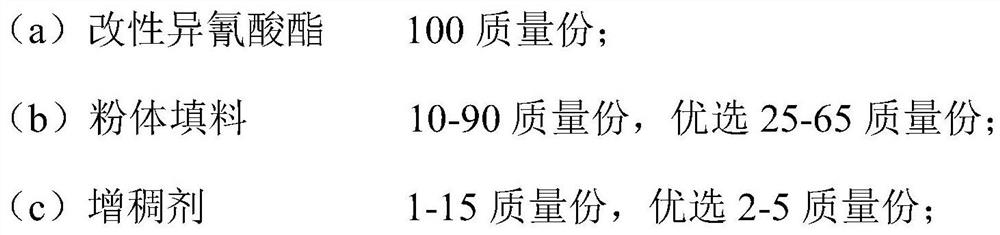

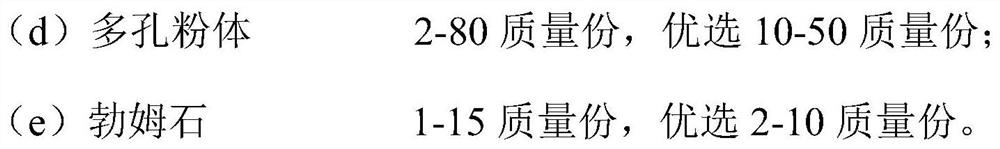

[0074] The plywood adhesive was compounded according to the formula in Table 1, and the panel test was carried out directly without aging after the compounding.

[0075] Table 1 embodiment 1-7 glue formula

[0076] PMDI MPEG water HPMC wheat flour calcium carbonate boehmite HAP Example 1 100 1 300 2 20 15 2 10 Example 2 100 15 300 2 20 15 2 10 Example 3 100 1 300 10 20 15 2 10 Example 4 100 1 300 2 50 15 2 10 Example 5 100 1 300 2 20 15 10 10 Example 6 100 1 300 2 20 5 2 10 Example 7 100 1 300 2 20 15 2 50

[0077] Table 2 embodiment 1-7 plate test result

[0078]

[0079] It can be obtained from Examples 1-7 that if the dosage of the substances in the formula is adjusted within the scope of the present invention, the boards can meet the requirements of Class I plywood, and the performance fluctuation of the boards is small.

Embodiment 8-12

[0088] Compared with Example 1, in Examples 8-12, the step of aging the glue solution is added, that is, after the glue solution is prepared, the glue solution is placed in an oven at 35°C for 0.5-8 hours and then taken out, and the viscosity test is carried out with a viscometer, and the plate is made at the same time evaluate.

[0089] Examples 8-12 The dosage of the components and the plate making steps are the same as those in Example 1, and the test results of the bond strength of the plates are shown in Table 4.

Embodiment 1

[0099] In Example 13, porous silica powder was used for component (d) in an amount of 10 parts by mass, and the amounts of other components and the plate making steps were the same as in Example 1. The test results of the bond strength of the plates are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com