Gas purification equipment for hydrogen production based on high-temperature fuel waste heat utilization

A technology for gas purification equipment and fuel, which is used in hydrogen/syngas production, liquid contact hydrogen separation, solid contact hydrogen separation, etc., and can solve the problems of poor absorption effect, low carbon dioxide dissolution rate, and insufficient purification. To achieve the effect of improving the removal rate, improving the absorption effect, and improving the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

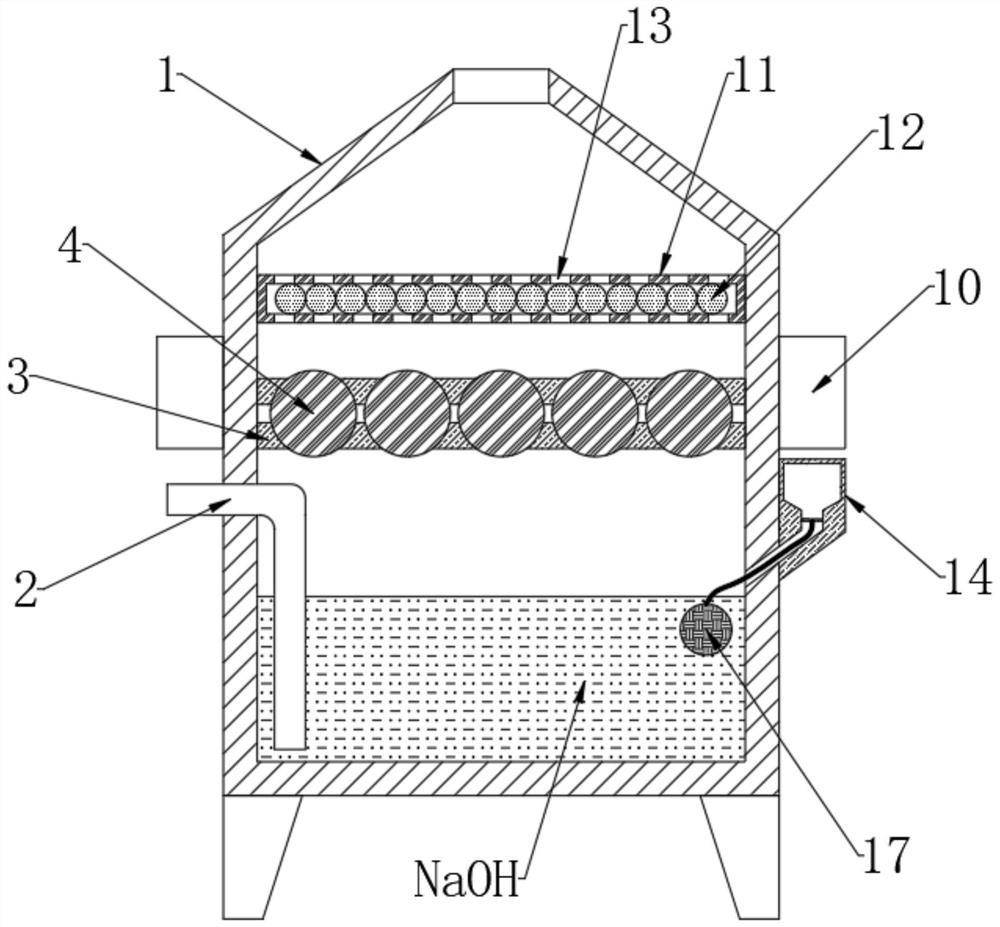

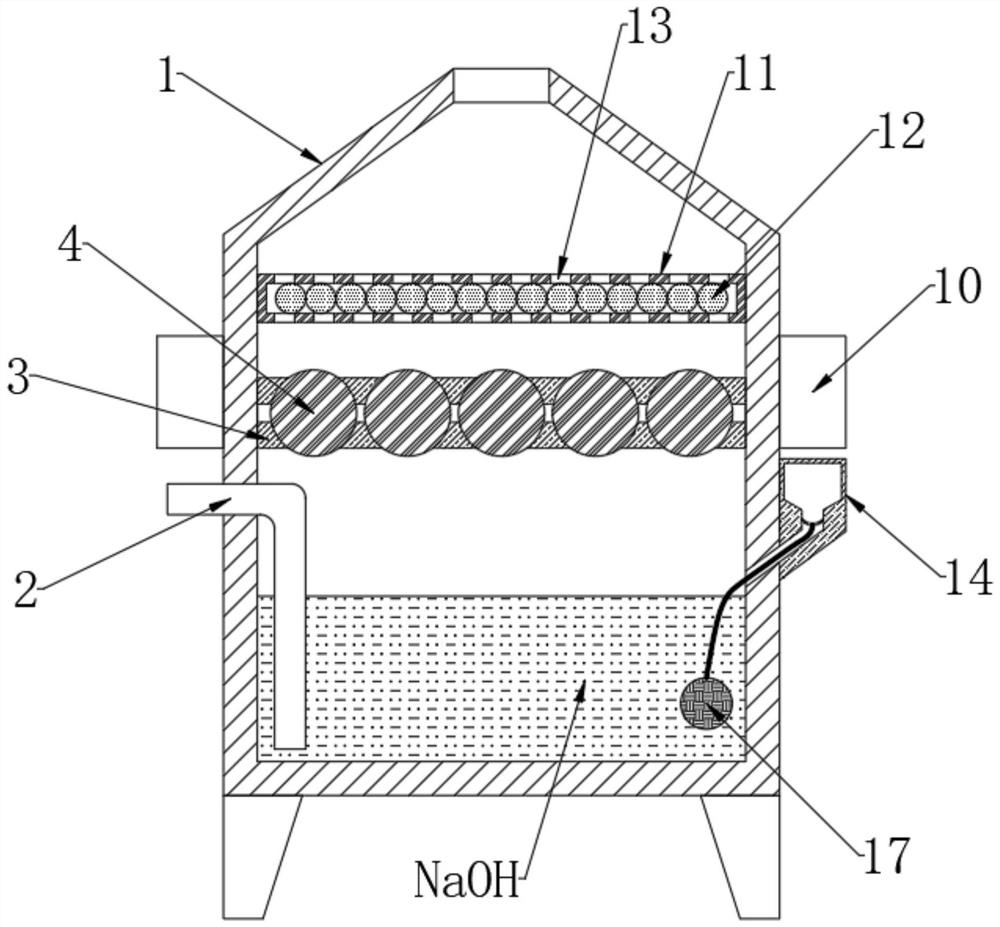

[0044] see Figure 1-7 , a gas purification equipment based on the utilization of high-temperature fuel waste heat to produce hydrogen, please refer to Figure 1-2 , including a purification box 1 with an air outlet on the upper end, and a driving device is provided at the bottom of the purification box 1, in order to allow the sodium hydroxide to fully absorb carbon dioxide, and also to quickly dissolve the newly added sodium hydroxide. The side is connected with an air intake pipe 2, the bottom of the purification box 1 is filled with sodium hydroxide absorption liquid, and the gas outlet end of the air intake pipe 2 is located at the bottom of the sodium hydroxide absorption liquid, and the inner wall of the upper end of the purification box 1 is fixedly connected with a partition plate 3, And a plurality of purification balls 4 are inlaid in the partition plate 3;

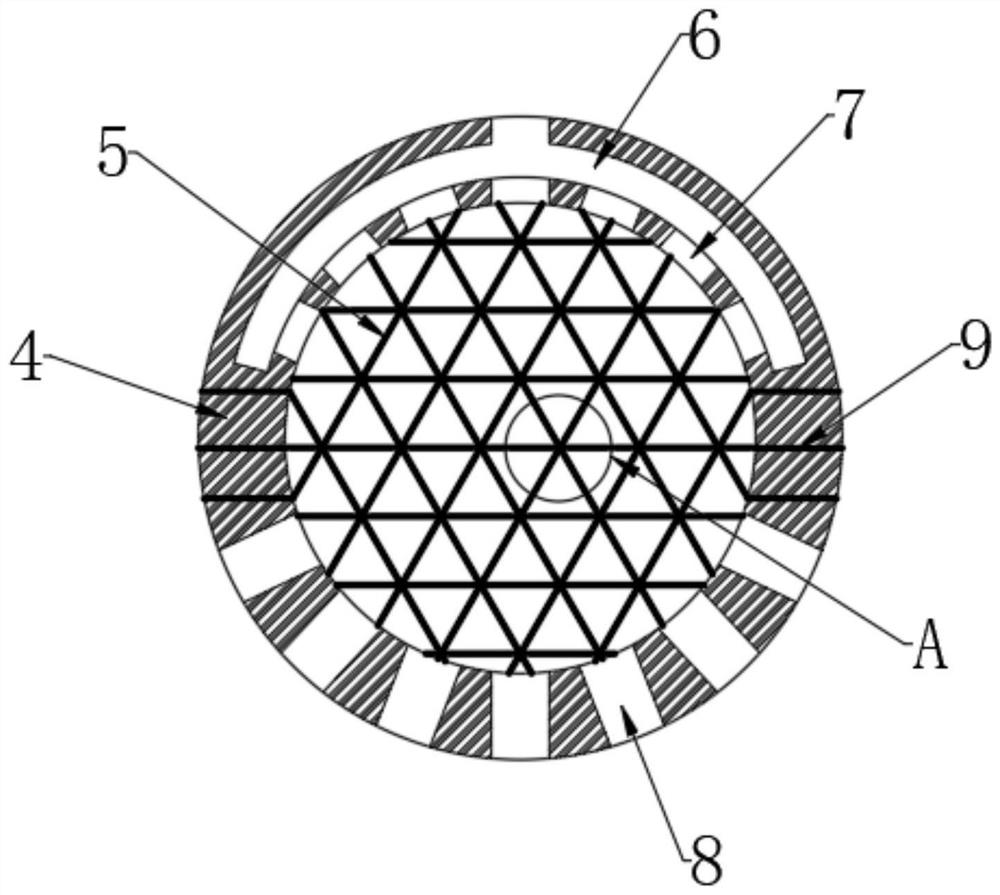

[0045] see Figure 3-4 , the inside of the purification ball 4 is provided with a cavity, and the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com