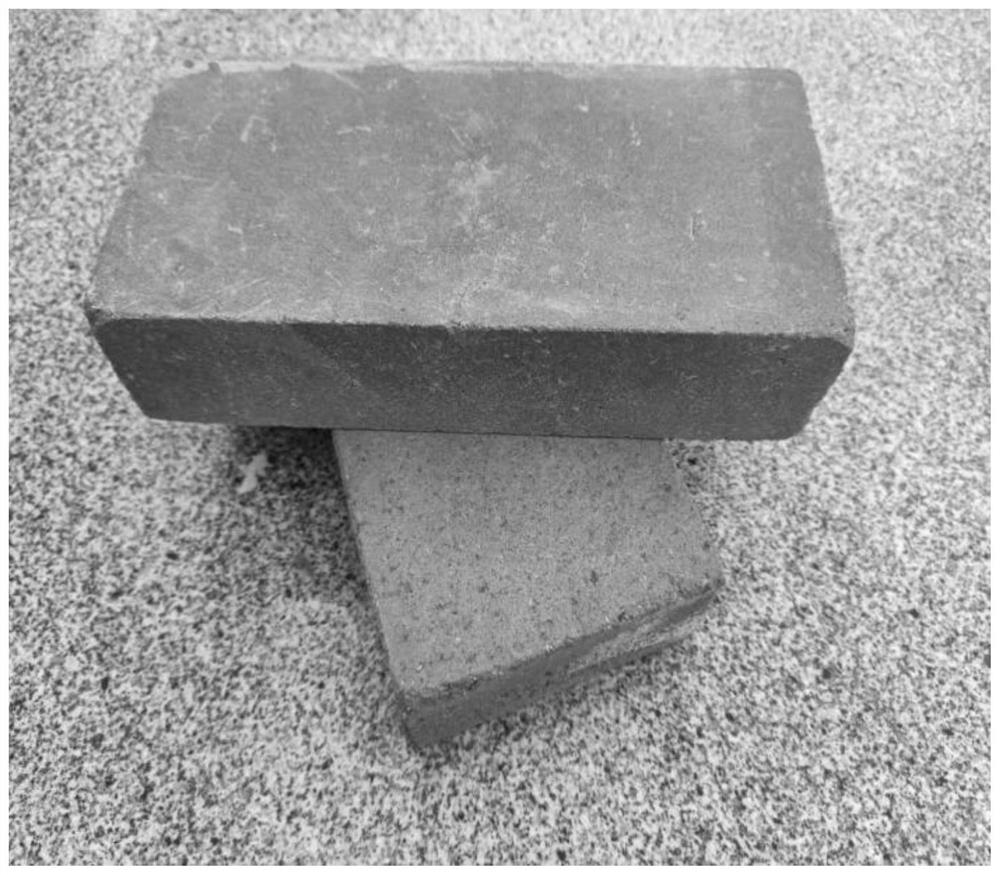

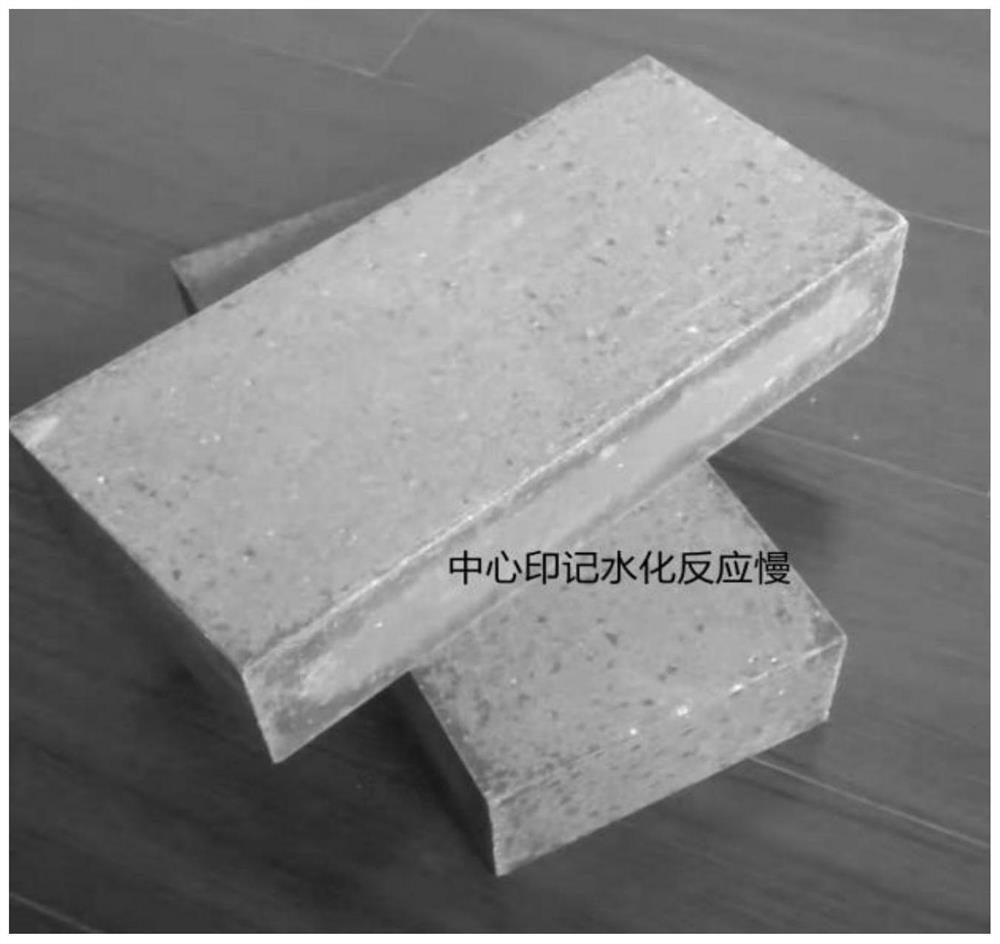

Regenerated sludge muck brick and preparation method thereof

A technology of silt slag and soil, applied in the field of recycled silt slag soil bricks and its preparation, can solve problems such as poor effect of finished bricks, uneven mixing of raw materials, and easy soil clods, etc., to ensure quality, shorten mixing time, and accelerate water production. The effect of chemical reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]A regenerated silt saffinating tile, including the following weight materials: 50 dirt, 5 bones, 1 cement; the soil curing agent; the soil is river sludge, the aggregate is a bean stone after incineration The particle size is 0.8 mm or less; the soil curing agent is 0.08 sodium salt sodium salt sodium sulfonated succinate, 1.3 lignin fibers, 30 hydroxypropylmethylcellulose, 5 sodium hydroxide, gather 15 parts of vinyl alcohol, 0.036 ~ parts of 2-ethylhexanol, 0.3 isopropanol, 400 parts of pure water.

Embodiment 2

[0026]A regenerated silt saffinating tile, including the following weight materials: 70 soil, 25 bones, 12 cement; the soil curing agent; the soil is a water plant sludge, the burns after burning The particle diameter is 0.8 mm or less; the soil curing agent is 0.10 parts of sodium succinate sodium salt, 3 of lignin fibers, 40 hydroxypropylmethylcellulose, 20 sodium hydroxide, polyethylene 22 parts of alcohol, 0.9 parts of 2-ethylhexanol, 0.9 isopropanol, and 900 parts of pure water.

Embodiment 3

[0028]A regenerated silt, including the following weight materials: 90 soils, 45 bones, 20 cement, soil curing agent; the soil is river sludge, the aggregate is garbage aggregate, incineration The subsequent smea is 0.8 mm or less; the soil curing agent is 0.09 sodium salt sodium succinous sodium salt, 2.5 parts of lignin fiber, 35 hydroxypropylmethylcellulose, sodium hydroxide. 15 copies of polyvinyl alcohol, 0.042 parts of 2-ethylhexanol, 0.6 isopropanol, and 600 parts of pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com