Thermal insulation mortar prepared from waste tiles and tiles and preparation method of thermal insulation mortar

A technology for thermal insulation mortar and bricks and tiles, which is applied in the field of building materials to achieve the effects of ensuring compression resistance, ensuring fire resistance and improving fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

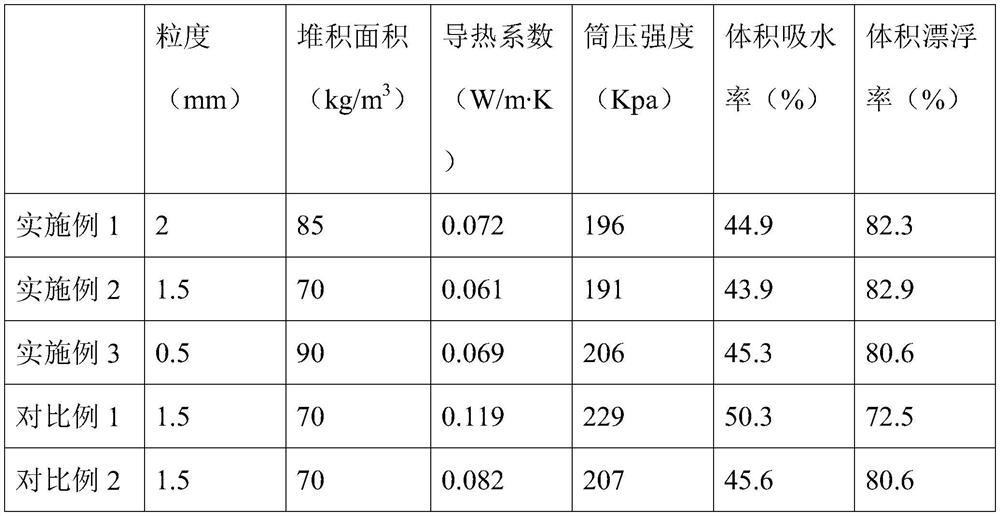

Embodiment 1

[0021] A kind of thermal insulation mortar prepared by using waste bricks and tiles includes by weight: 400 parts of aluminate cement, 280 parts of quartz sand, particle size of 2mm and accumulation area of 85kg / m 3 300 parts of modified waste brick and tile particles, 9 parts of methyl cellulose ether, 2 parts of polycarboxylate powder superplasticizer, 3 parts of acrylic latex powder;

[0022] The modified waste bricks and tiles particles are prepared through the following steps: (1) Treatment of waste bricks and tiles: sort waste bricks and tiles from construction waste, and use a crushing device to crush the waste bricks and tiles, and the particle size is 0.8mm; (2) Acidification of waste brick and tile particles: add 800 parts by weight of water to the waste brick and tile micropowder obtained in step (1) for beating, then add hydrochloric acid. Dehydration to obtain acid-activated waste brick and tile particles; (3) preheating and dehydration: preheating the waste bri...

Embodiment 2

[0025] A thermal insulation mortar prepared by using waste bricks and tiles includes, in parts by weight: 500 parts of Portland cement, 100 parts of quartz sand, a particle size of 1.5mm, and a stacking area of 70kg / m 3 300 parts of modified waste brick and tile particles, 10 parts of hydroxypropyl methylcellulose ether, 5 parts of polycarboxylate powder superplasticizer, 4 parts of ethylene-vinyl acetate copolymer latex powder;

[0026]Modified waste brick and tile particles are prepared through the following steps: (1) Treatment of waste brick and tile: sort waste brick and tile from construction waste, use a crushing device to crush the waste brick and tile, and the particle size is 0.6mm; (2) Acidification of waste brick and tile particles: add 1000 parts by weight of water to the waste brick and tile micropowder obtained in step (1) to make a slurry, then add hydrochloric acid, the amount of hydrochloric acid is 1.2 times the cation exchange capacity of the waste brick a...

Embodiment 3

[0029] A kind of thermal insulation mortar prepared by using waste bricks and tiles includes, in parts by weight: 420 parts of Portland cement, 180 parts of quartz sand, a particle size of 0.5mm and a stacking area of 90kg / m 3 400 parts of modified waste brick and tile particles, 7 parts of hydroxypropyl methylcellulose ether, 4 parts of polycarboxylate powder superplasticizer, 2 parts of ethylene-vinyl acetate copolymer latex powder;

[0030] The modified waste bricks and tiles particles are prepared through the following steps: (1) Treatment of waste bricks and tiles: sort waste bricks and tiles from construction waste, and use a crushing device to crush the waste bricks and tiles, and the particle size is 0.3mm; (2) Acidification of waste brick and tile particles: add 500 parts by weight of water to the waste brick and tile micropowder obtained in step (1) for beating, then add hydrochloric acid. Dehydration to obtain acid-activated waste brick and tile particles; (3) pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com