Preparation method of modified polyvinyl chloride

A technology of polyvinyl chloride, manufacturing method, applied in the field of chemical industry, can solve problems such as poor mechanical properties, restricted development, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of manufacture method of modified polyvinyl chloride, its specific scheme is as follows:

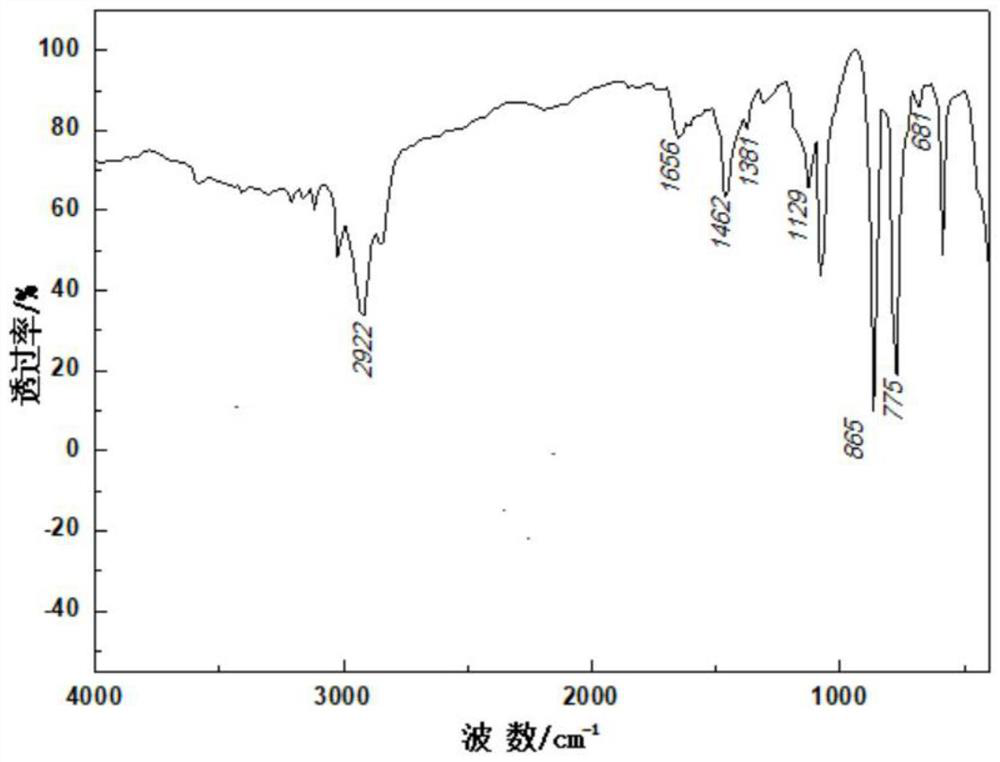

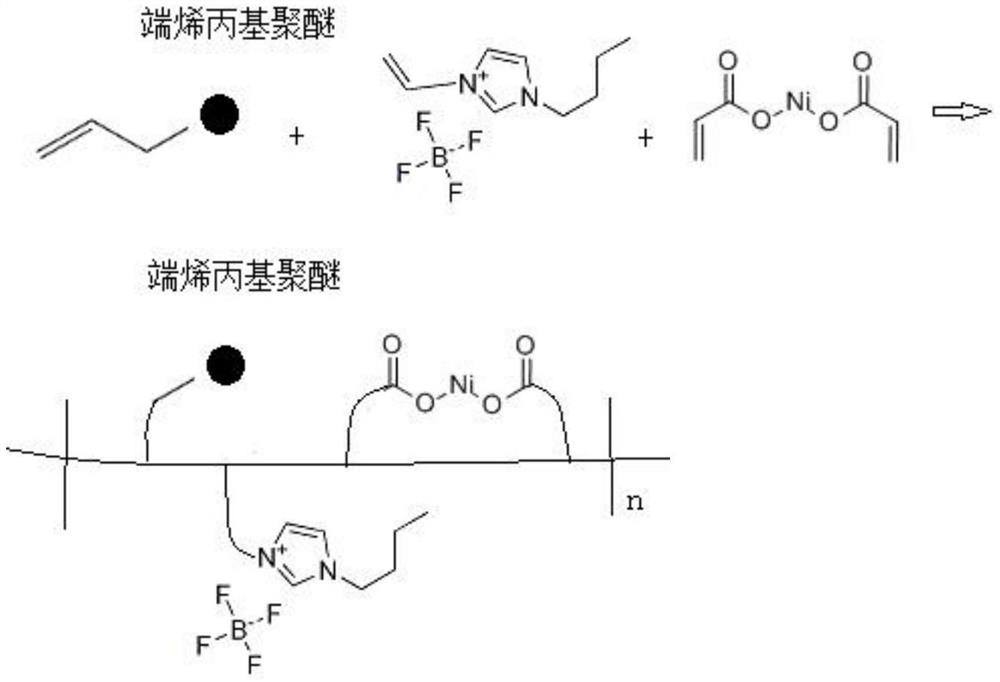

[0026] Pretreatment of 100g polyvinyl chloride pellets: Soak polyvinyl chloride pellets in acetone solution for 30 minutes, then soak in 60% ethanol solution for 20 minutes, then wash with deionized water to remove ethanol, and finally immerse them in 60°C Dry for 3 hours; carry out plasma treatment: place the cleaned polyvinyl chloride pellets in a plasma high-vacuum preparation chamber. 3 / s, the power is 40w, and the processing time is 10s; surface grafting reaction: add the processed polyvinyl chloride pellets to 500g organic solvent, and after the dispersion is uniform, add 5g terminal allyl polyether, 0.23g of 1- Vinyl-3-butylimidazole tetrafluoroborate, CAS: 1033461-44-7, 0.5g nickel acrylate, mix well and bubble with nitrogen for 5min, then add 0.1g benzoyl peroxide, stir and mix for 5min Raise the temperature to 85°C and react for 10 minutes. After the completion,...

Embodiment 2

[0034] A kind of manufacture method of modified polyvinyl chloride, its specific scheme is as follows:

[0035] Pretreatment of 120g polyvinyl chloride pellets: Soak polyvinyl chloride pellets in acetone solution for 40 minutes, then soak in 75% ethanol solution for 50 minutes, then wash with deionized water to remove ethanol, and finally immerse them in 70°C Dry for 4 hours; carry out plasma treatment: place the cleaned polyvinyl chloride pellets in the plasma high-vacuum preparation chamber, and after vacuuming, pass in argon and oxygen, and the total flow rate of the gas is 30cm 3 / s, the power is 50w, and the processing time is 30s; surface grafting reaction: add the processed polyvinyl chloride pellets to 550g organic solvent, and after the dispersion is uniform, add 12g terminal allyl polyether, 1.23g of 1- Vinyl-3-butylimidazolium tetrafluoroborate, CAS: 1033461-44-7, 0.8g nickel acrylate, mix well and bubble with nitrogen for 8min, then add 0.3g benzoyl peroxide, stir a...

Embodiment 3

[0043] A kind of manufacture method of modified polyvinyl chloride, its specific scheme is as follows:

[0044] Pretreatment of 150g of polyvinyl chloride pellets: Soak the polyvinyl chloride pellets in acetone solution for 60 minutes, then soak in 95% ethanol solution for 60 minutes, then wash with deionized water to remove ethanol, and finally immerse them in 80°C Dry for 6 hours; carry out plasma treatment: place the cleaned polyvinyl chloride pellets in the plasma high-vacuum preparation chamber, and after vacuuming, pass in argon and oxygen, and the total flow rate of the gas is 40cm 3 / s, the power is 60w, and the processing time is 40s; surface grafting reaction: add the processed polyvinyl chloride pellets to 600g organic solvent, and after the dispersion is uniform, add 20g terminal allyl polyether, 2.52g of 1- Vinyl-3-butylimidazolium tetrafluoroborate, CAS: 1033461-44-7, 1.7g nickel acrylate, mix well and bubble with nitrogen for 10min, then add 0.5g benzoyl peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com