A kind of zirconium hydroxide nanosheet/nanofiber composite membrane and preparation method thereof

A technology of nanofiber membrane and zirconium hydroxide, which is applied in fiber treatment, synthetic fiber, fiber type, etc., can solve the problems of long synthesis cycle, unstable application performance, and difficult to control the morphology of metal hydroxide nanosheets. Achieve the effect of easy size, stable structure and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

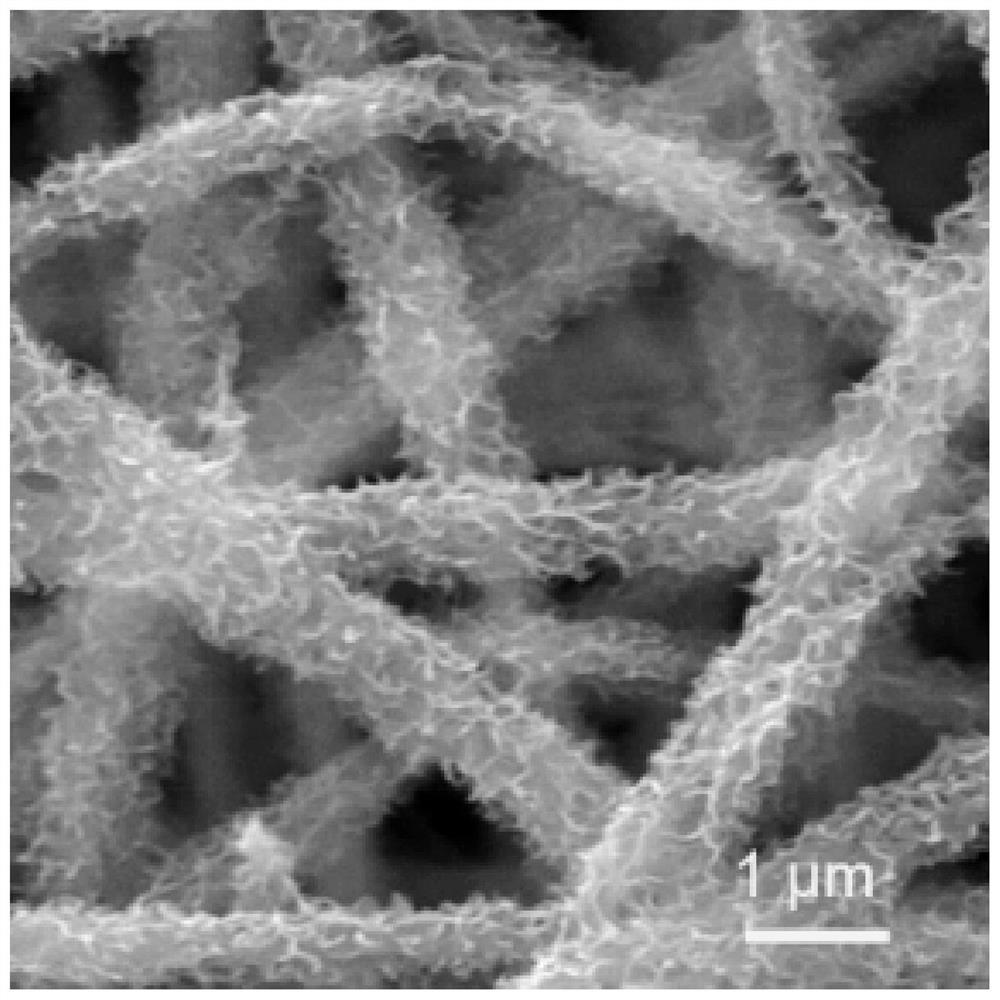

[0034] A preparation method of zirconium hydroxide nanosheet / nanofiber composite film:

[0035] (1) 0.5g of polyvinylpyrrolidone (PVP) was dissolved in 12g of n-propanol, stirred at room temperature for 4h until a homogeneous system was formed, and a high molecular polymer solution with a mass fraction of 4% was prepared;

[0036] (2) Add 10.4g zirconium n-propoxide to the high molecular polymer solution, the mass ratio of zirconium n-propoxide and high molecular polymer solution is 1:1.2, and then stir for 3h at normal temperature to obtain clear and transparent static electricity Spinning precursor solution;

[0037] (3) Slowly inject the electrospinning precursor solution into the syringe, and then in an environment with an air humidity of 25±5% and a temperature of 20±2°C, the voltage is 10kV, the perfusion rate is 0.5mL / h, and the spinning The wire distance is 10cm, the drum speed of the receiving device is 5r / min, and the process parameters of the slide table speed are ...

Embodiment 2

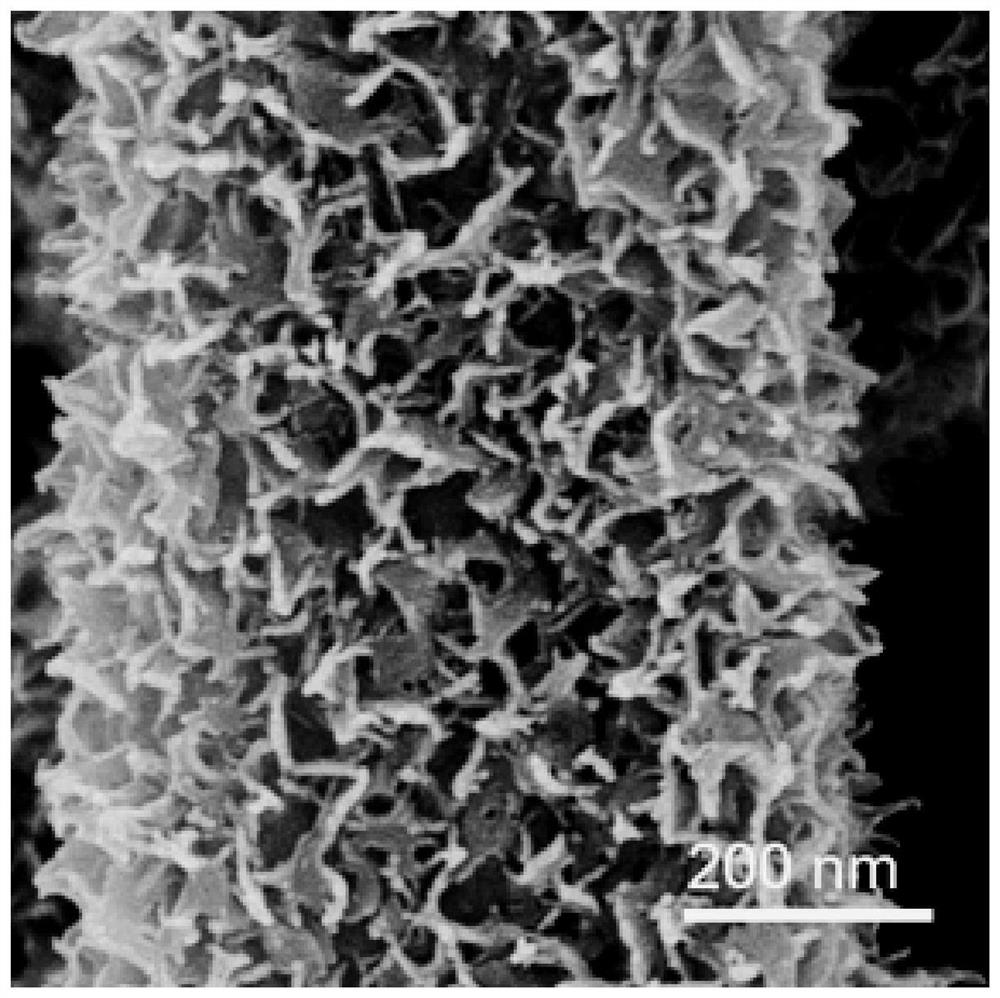

[0044] A preparation method of zirconium hydroxide nanosheet / nanofiber composite film:

[0045] (1) Dissolve 1 g of polyvinylpyrrolidone (PVP) in 24 g of N'N-dimethylformamide, stir for 5 hours at room temperature until a homogeneous system is formed, and prepare a high molecular polymer solution with a mass fraction of 4%;

[0046] (2) Add 20.8g zirconium isopropoxide to the high molecular polymer solution, the mass ratio of zirconium isopropoxide and high molecular polymer solution is 1:1.2, and then stir for 4h at normal temperature to obtain a clear and transparent electrostatic Spinning precursor solution;

[0047] (3) Slowly inject the electrospinning precursor solution into the syringe, and then in an environment with an air humidity of 26±5% and a temperature of 21±2°C, the voltage is 20kV, the perfusion rate is 1.5mL / h, and the spinning The wire distance is 15cm, the drum speed of the receiving device is 15r / min, and the speed of the slide table is 15cm / min, and the ...

Embodiment 3

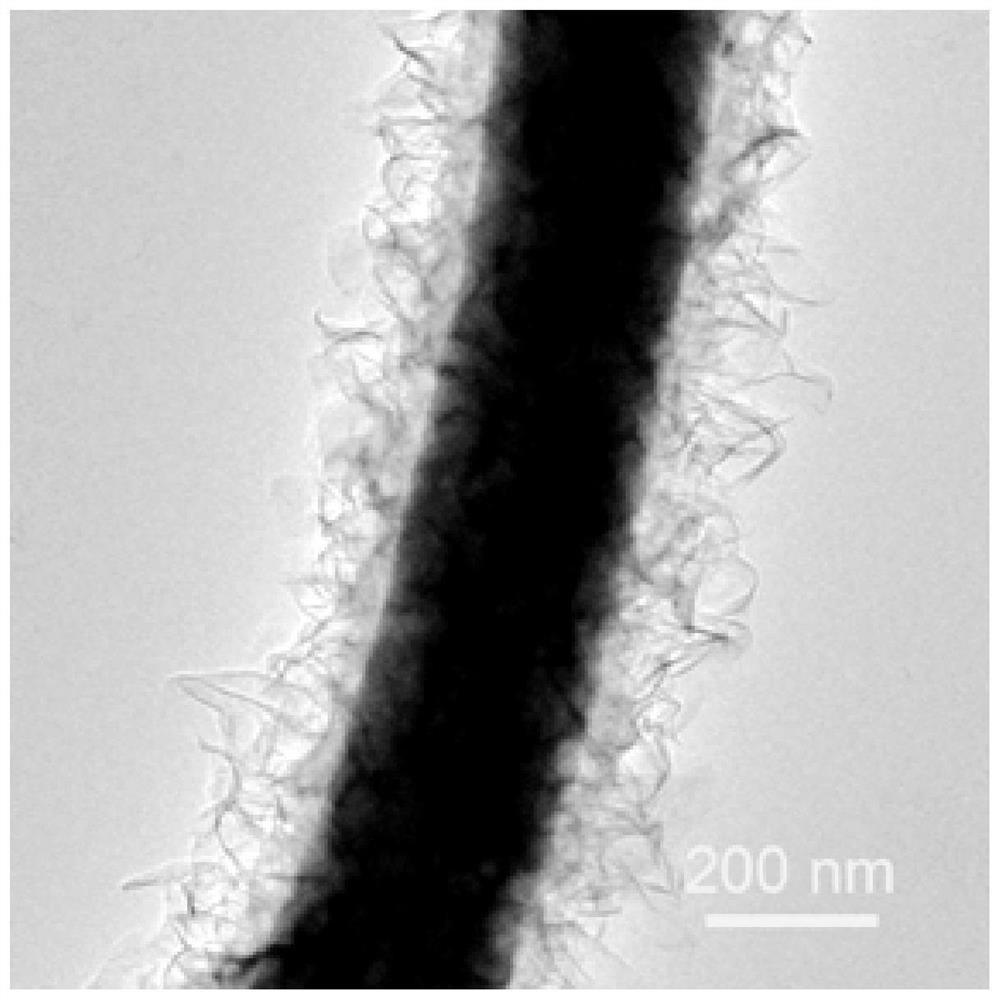

[0052] A preparation method of zirconium hydroxide nanosheet / nanofiber composite film:

[0053] (1) Dissolve 1g of polyvinylpyrrolidone (PVP) in a mixed solvent of 12g of ethanol and 12g of n-propanol, stir for 6 hours at room temperature until a homogeneous system is formed, and prepare a high molecular polymer solution with a mass fraction of 4%;

[0054] (2) Add 20.8g zirconium acetate to the high molecular polymer solution, the mass ratio of zirconium acetate and high molecular polymer solution is 1:1.2, and then stir for 5h at room temperature to obtain a clear and transparent electrospinning precursor solution;

[0055] (3) Slowly inject the electrospinning precursor solution into the syringe, and then in an environment with an air humidity of 27±5% and a temperature of 22±2°C, the voltage is 30kV, the perfusion rate is 2.5mL / h, and the spinning The wire distance is 20cm, the drum speed of the receiving device is 25r / min, and the speed of the slide table is 25cm / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com