Method for determining 191 pesticide residues through combination of high-oil complex matrix sample pretreatment technology and UPLC-MSMS

A technology for sample pretreatment and complex matrix, applied in the field of pesticide residue analysis, it can solve the problems of not being able to adapt to a large number of samples and not meeting the needs of pesticide residue detection, saving sample preparation time, liberating labor, and achieving good separation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

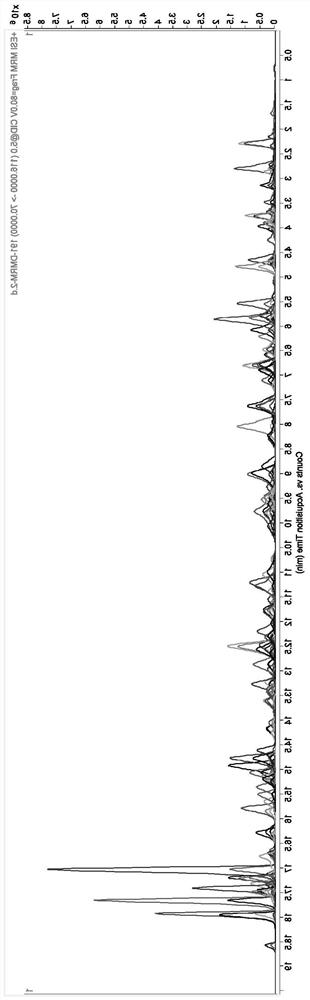

Image

Examples

Embodiment 1

[0030] 1 Materials and methods

[0031] 1.1 Materials and reagents

[0032] 1290 high performance liquid chromatography and 6460 triple quadrupole mass spectrometer (Agilent, USA); automatic sample preparation system (Beijing Benli Technology Co.); N-112 nitrogen blowing concentrator (Organomation Associates, USA), TRIOTM-1N vortex Rotary stirrer (ASONE Company, Japan), Milli-Q ultrapure water machine (Millipore Company, USA), PL602-L electronic balance (Mettler-Toledo Company, Switzerland), ultrasonic cleaner (Kunshan Ultrasonic Instrument Co., Ltd., Jiangsu, China).

[0033] 191 kinds of pesticide standard substances: purity ≥ 95% (Tianjin Alta Company); acetonitrile is chromatographically pure (Honeywell Company, USA); adsorbent: ethylenediamine-N-propylsilane (PSA), octadecylsilane bonded Silica gel (C18) adsorbent (Tianjin Bonna-Agela Company); graphitized non-porous carbon (ENVI-Carb), carbon eighteen bonded zirconium glue (Z-Sep + ) (Supelco Company, U.S.); formic aci...

Embodiment 2

[0063] Using the method of the present invention to actually measure 20 batches of commercially available cassia bark, a total of 12 batches of pesticide residues were detected, and 17 kinds of pesticides were detected, of which the highest concentration of fenoxycarb was 49.3ug / kg, and the eighth batch of samples detected The maximum number of pesticides was 5, and acetochlor, paclobutrazol, benalaxyl, azoxystrobin and triazophos were detected respectively.

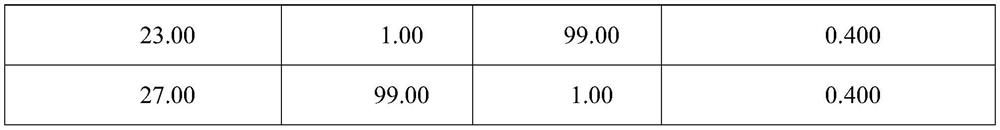

[0064] Table 5 Types and contents of pesticides in cinnamon measured samples

[0065]

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com