High-fiber steamed bun preparation equipment and preparation process thereof

A preparation process and steamed bread technology, which are applied in the field of high-fiber steamed bread preparation equipment and the preparation process thereof, can solve the problems of low steam utilization rate, huge equipment volume, etc., and achieve the effects of reducing time, absorbing gastrointestinal toxins, and controlling blood lipid and blood sugar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

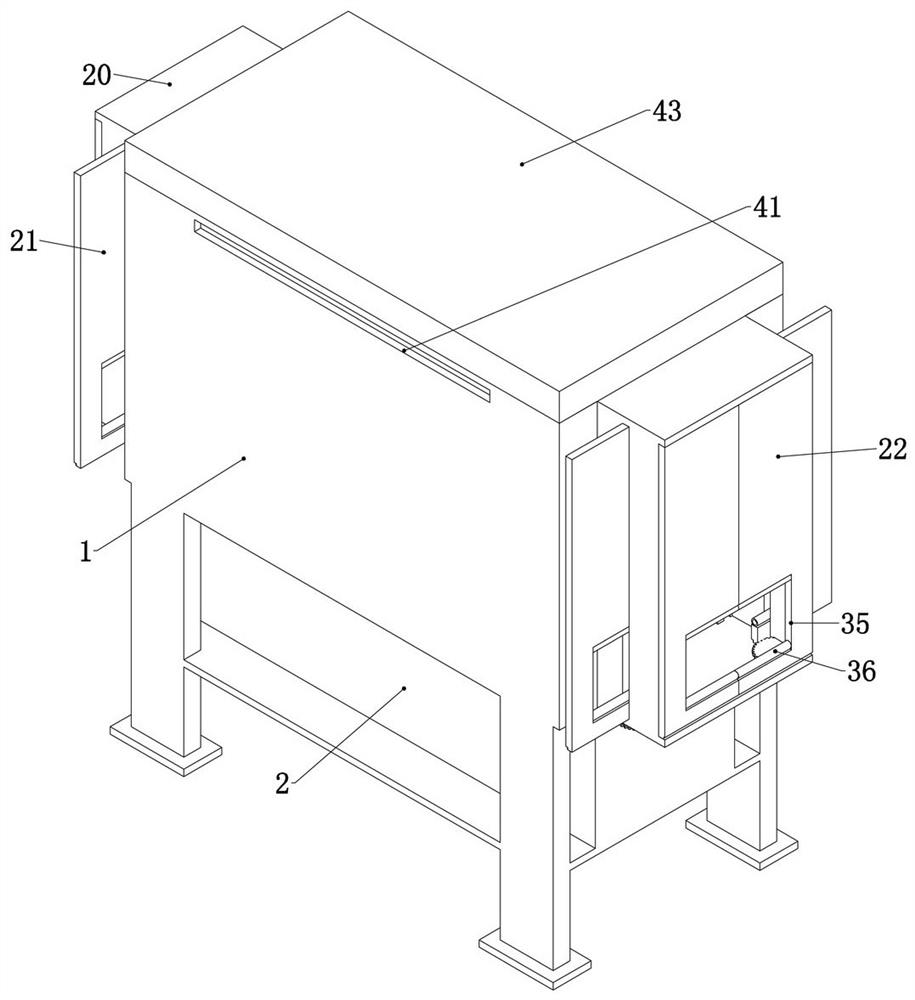

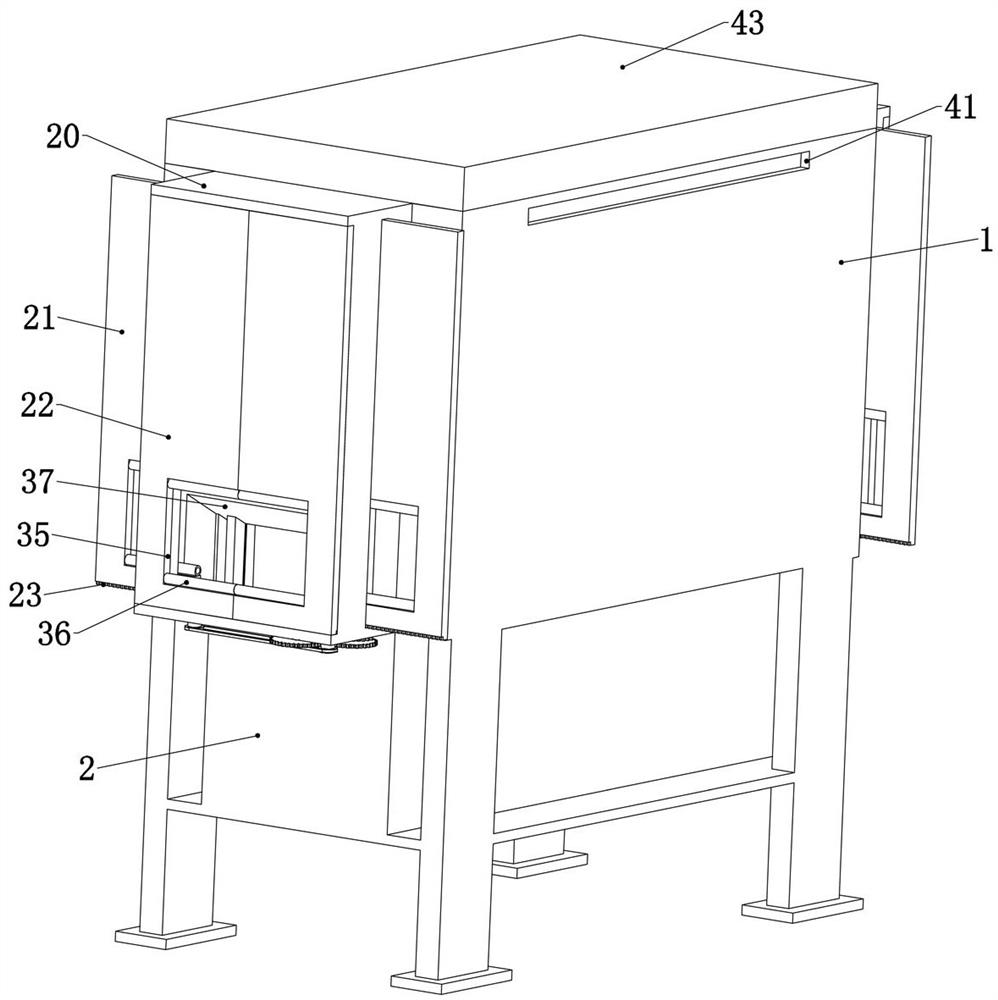

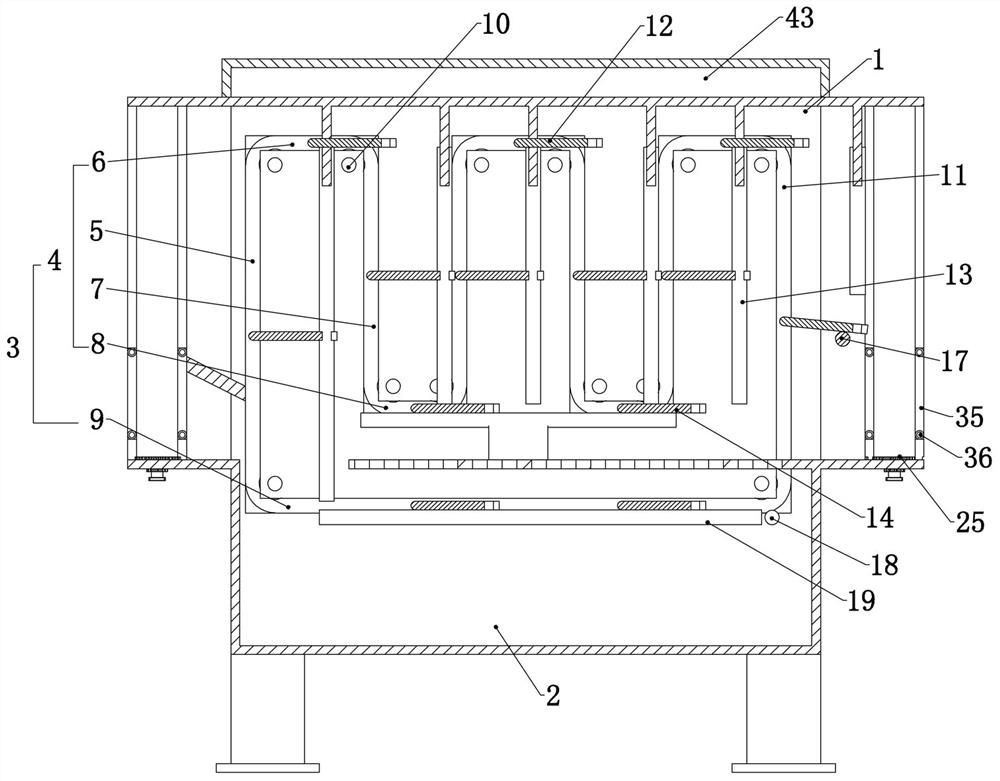

[0054]EXAMPLIN, the present invention is a high fiber steamed steamed bun preparing device and a preparation process thereof, including a case 1, which is a hollow casing 1, and the left and right ends are connected to the conveying device, referenceimage 3 The conveying device enters the box 1 from the left side from the left side, and the processed surface is delivered from the right side to the next step, the lower end of the box 1 fixed communication with steam generation equipment 2, box The lower end fixation of the body 1 has an equipment bin. The steam generating apparatus 2 is placed in the equipment bar, and the steam generating device 2 is a common steam generator, which can steam the surface of the casing 1, characterized in that the box is There is a closed loop slide rail 3 in the inner two sides of the body, including a plurality of S-shaped slide rails 4, and the S-shaped rail 4 of each set includes a front vertical track 5 that communicates with each other. The tran...

Embodiment 2

[0060]Embodiment 2, on the basis of the first example, referenceimage 3 ,Figure 4 The last side of the back vertical rail 7 is provided with a horizontal axis 17 fixed to the casing 1, which is located below the last vertical axis 13, and it is important to note that the last vertical The lower end surface of the shaft 13 is higher than the lower end surface of the remaining vertical shaft 13, which allows the pallet 12 to move downwardly to a certain time along the last, and the positioning ring 16 and the corresponding vertical shaft 13 are detached. When the pallet 12 still does not move to the bottom end of the rear vertical rail 7, at which time the pallet 12 is turned down and the lower surface of the pallet 12 and the horizontal shaft 17 are in contact, the pallet 12 is inclined, the surface is slid along the pallet 12. By the subsequent conveying device, as the rotating shaft 15 continues to move with the conveyor belt 11, the pallet 12 is gradually discharged until the pall...

Embodiment 3

[0061]Example 3. On the basis of the first example, both ends of the casing 1 are fixedly coupled with a middle transfer case 20, and the two middle transfer cases 20 are disposed at the inlet and outlet of the casing 1, two of the two The middle transfer box 20 and the casing 1 are in communication with two inner door 21, and the two inner door 21 are close to each other and in contact, and the middle transfer case 20 can be closed, and the middle transfer case 20 is part of the outside. Sliding has two outer door 22, and the two external door 22 are close to each other and the middle transfer box 20 can also be closed;

[0062]Each of the lower ends of the inner door 21 is fixedly coupled to the inner door rack 23, and each of the outer door 22 is fixedly connected to the outer gate 24, and the adjacent interior door 21 and the outer door 22 are provided. The drive gear 25 is rotatably coupled to the bottom surface of the middle transfer case 20, the drive gear 25, and the outer door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com