Nano magnetic adsorbent with core-shell structure and preparation method of nano material absorbent

A nano-magnetic, core-shell structure technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of easy loss of magnetic materials, insufficient specific surface area, and unsatisfactory adsorbent effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

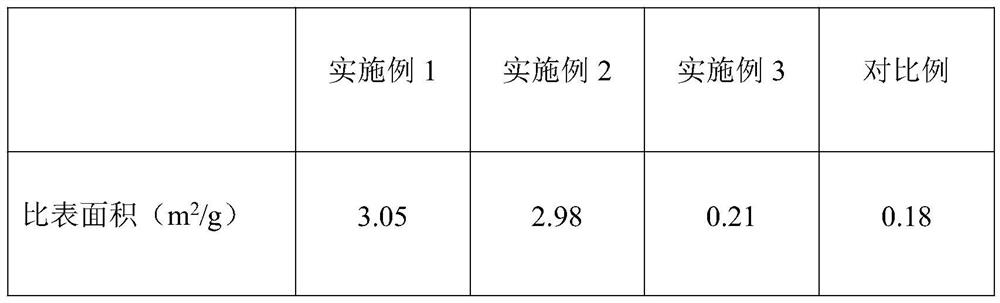

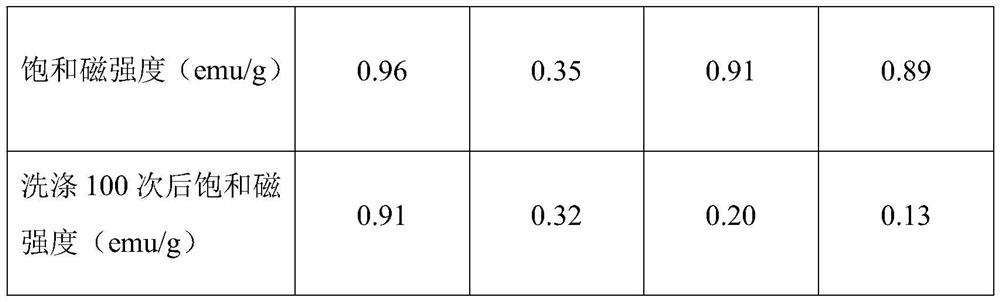

Embodiment 1

[0037] A nano-magnetic adsorbent with a core-shell structure, mainly comprising: 13 parts of carboxyl-modified magnetic particles, 10 parts of β-cyclodextrin, 65 parts of modified chitosan, 8 parts of epoxy chlorine propane and 4 parts formaldehyde.

[0038] A preparation method of a nano-magnetic adsorbent with a core-shell structure, the preparation method of the nano-magnetic adsorbent with a core-shell structure mainly includes the following preparation steps:

[0039] (1) Mix cholesterol and pyridine in a beaker at a mass ratio of 1:35, and add succinic anhydride that is 1 to 1.2 times the mass of cholesterol to the beaker, stir and react at a temperature of 72°C for 3 hours, then concentrate by rotary evaporation, To obtain the modified cholesterol base, mix the modified cholesterol base with 95% ethanol aqueous solution at a mass ratio of 1:10, and filter to obtain the modified cholesterol;

[0040] (2) Mix the modified cholesterol and chitosan solution obtained in ste...

Embodiment 2

[0049] A nano-magnetic adsorbent with a core-shell structure, mainly comprising: 13 parts of magnetic particles, 10 parts of β-cyclodextrin, 65 parts of modified chitosan, 8 parts of epichlorohydrin and 4 parts by weight. part formaldehyde.

[0050] A preparation method of a nano-magnetic adsorbent with a core-shell structure, the preparation method of the nano-magnetic adsorbent with a core-shell structure mainly includes the following preparation steps:

[0051] (1) Mix cholesterol and pyridine in a beaker at a mass ratio of 1:35, and add succinic anhydride that is 1 to 1.2 times the mass of cholesterol to the beaker, stir and react at a temperature of 72°C for 3 hours, then concentrate by rotary evaporation, To obtain the modified cholesterol base, mix the modified cholesterol base with 95% ethanol aqueous solution at a mass ratio of 1:10, and filter to obtain the modified cholesterol;

[0052] (2) Mix the modified cholesterol and chitosan solution obtained in step (1) in ...

Embodiment 3

[0061] A nano-magnetic adsorbent with a core-shell structure, mainly comprising: 13 parts of carboxyl-modified magnetic particles, 10 parts of β-cyclodextrin, 65 parts of chitosan, 8 parts of epichlorohydrin and 4 parts formaldehyde.

[0062] A preparation method of a nano-magnetic adsorbent with a core-shell structure, the preparation method of the nano-magnetic adsorbent with a core-shell structure mainly includes the following preparation steps:

[0063] (1) Chitosan and racemic polylactic acid are mixed in dimethyl sulfoxide which is 8 times the mass of polylactic acid at a mass ratio of 1:1. After mixing and dialysis, the dialysis product is freeze-dried to obtain pretreated microspheres;

[0064](2) Mix the pretreated microspheres obtained in step (1) with water at a mass ratio of 1:12, add epichlorohydrin 0.15 times the mass of the pretreated microspheres, and stir for 4 hours at a temperature of 50°C , and filtered to obtain microsphere blanks. Dry the microsphere bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com