Touch panel and manufacturing method thereof

A technology for touch panels and manufacturing methods, applied in ion implantation plating, coatings, instruments, etc., can solve problems such as metal reflection and color incongruity, and achieve the effect of reducing reflectivity and improving incongruity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

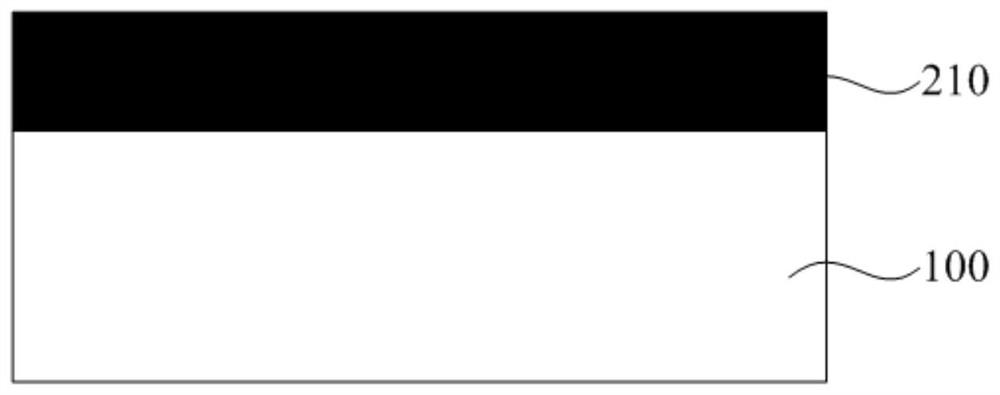

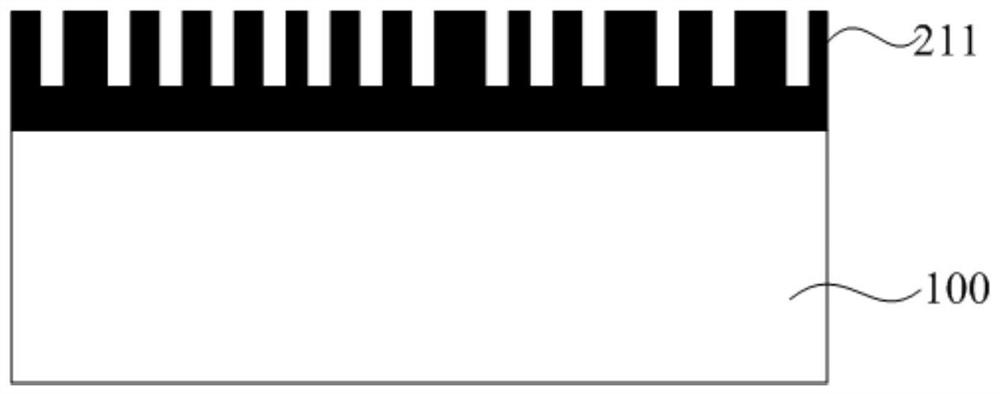

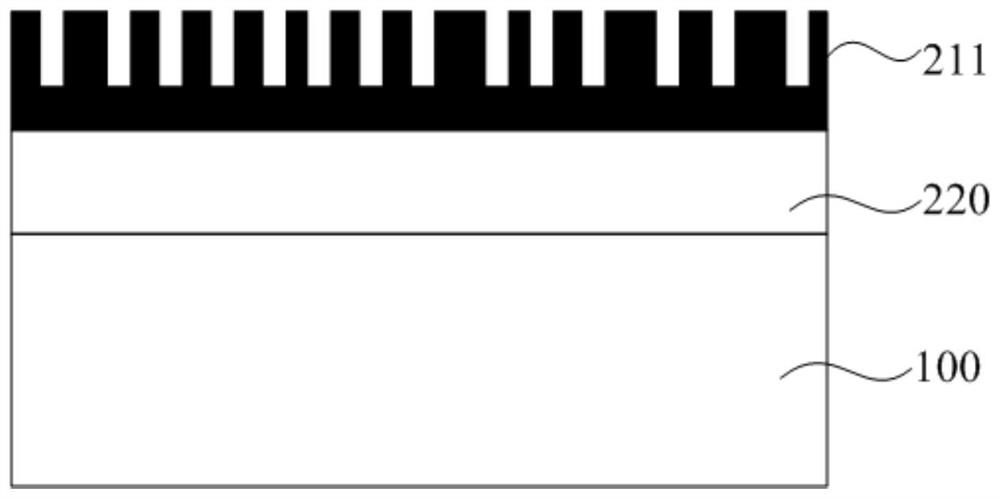

Image

Examples

Embodiment 1

[0079] Example 1: First, a blackened copper alloy layer is plated on a transparent substrate by vacuum evaporation, wherein the coating atmosphere is a mixture of oxygen and argon; then, the blackened copper alloy is treated with roughening and / or anti-oxidation potions On the surface of the copper alloy layer, a roughened layer is formed on the surface of the blackened metal copper grid layer. Wherein, the coarsening and / or anti-oxidation potion includes 15% formic acid, 15% copper formate, 2% phenyltriazole, 0.5% guanidine hydrochloride and 0.5% monoethanolamine, and the rest is pure water.

Embodiment 2

[0080] Embodiment 2: First, a pure copper layer is plated on a transparent substrate by vacuum evaporation, wherein the coating atmosphere is pure argon with a purity of more than 99%; then, a copper layer is plated on a transparent substrate by vacuum evaporation. Cover the blackened copper alloy layer, wherein the plating atmosphere is a mixture of oxygen and argon; then, use roughening and / or anti-oxidation potions to treat the surface of the blackened copper alloy layer, so that the surface of the blackened metal copper grid layer A roughened layer is formed. Wherein, the coarsening and / or anti-oxidation potion includes 15% formic acid, 15% copper formate, 2% phenyltriazole, 0.5% guanidine hydrochloride and 0.5% monoethanolamine, and the rest is pure water.

[0081] The specific test method of roughness and reflectivity: use surface roughness tester (or atomic force microscope) to test the roughness of above-mentioned embodiment and comparative example touch panel; Use vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com