Electrode material of lithium battery and preparation method of electrode material

An electrode material and lithium battery technology, applied in battery electrodes, electrode manufacturing, lithium batteries, etc., can solve problems such as cycle performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

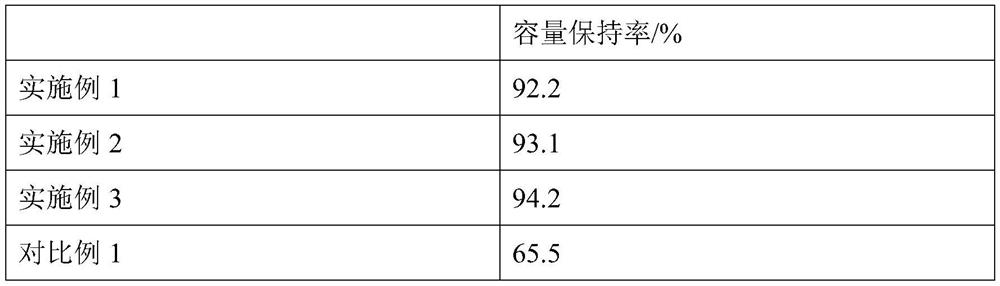

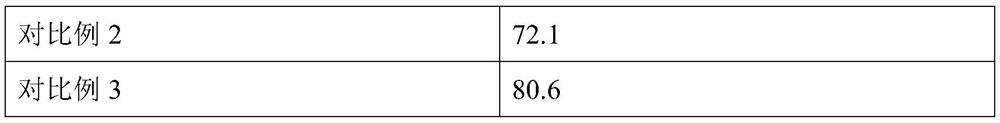

Examples

Embodiment 1

[0036] Mix the sulfur carrier and sulfur, the mass of the sulfur is 30% of the mass of the sulfur carrier, and then in the muffle furnace, under the condition of being isolated from the air, at a temperature of 155 ° C, keep warm for 12 hours, and cool with the furnace to Room temperature, discharge, and get the sulfur-loaded cathode material;

[0037] In parts by weight, take 80 parts of sulfur-loaded positive electrode material, 3 parts of conductive carbon black, 4 parts of water-based glue LA133, 20 parts of water, and 40 parts of isopropanol, and first stir and mix the sulfur-loaded positive electrode material and conductive carbon black to form Mix the dry powder, mix the water-based glue LA133, water and isopropanol to form a glue solution, then add the glue solution to the mixed dry powder in 3 batches, knead and stir for 6 hours, and discharge to obtain the positive electrode slurry;

[0038] Then apply the positive electrode slurry on the surface of the current colle...

Embodiment 2

[0043] Mix the sulfur carrier and sulfur, the mass of the sulfur is 35% of the mass of the sulfur carrier, and then in the muffle furnace, under the condition of being isolated from the air, at a temperature of 155 ° C, heat preservation and sulfurization for 14 hours, and cool with the furnace to Room temperature, discharge, get the sulfur-loaded cathode material;

[0044] In parts by weight, take 100 parts of sulfur-loaded positive electrode material, 4 parts of conductive carbon black, 5 parts of water-based glue LA133, 25 parts of water, and 45 parts of isopropanol, and first stir and mix the sulfur-loaded positive electrode material and conductive carbon black to form Mix the dry powder, and mix the water-based glue LA133, water and isopropanol to form a glue solution, then add the glue solution to the mixed dry powder in 3 batches, knead and stir for 7 hours, and discharge to obtain the positive electrode slurry;

[0045]Then apply the positive electrode slurry on the su...

Embodiment 3

[0050] Mix the sulfur carrier and sulfur, the mass of the sulfur is 40% of the mass of the sulfur carrier, and then in the muffle furnace, under the condition of being isolated from the air, at a temperature of 155 ° C, heat preservation and sulfurization for 16 hours, and cool with the furnace to Room temperature, discharge, and get the sulfur-loaded cathode material;

[0051] In parts by weight, take 120 parts of sulfur-loaded positive electrode material, 5 parts of conductive carbon black, 8 parts of water-based glue LA133, 30 parts of water, and 50 parts of isopropanol, and first stir and mix the sulfur-loaded positive electrode material and conductive carbon black to form Mix the dry powder, mix the water-based glue LA133, water and isopropanol to form a glue solution, then add the glue solution to the mixed dry powder in 3 batches, knead and stir for 8 hours, and discharge to obtain the positive electrode slurry;

[0052] Then apply the positive electrode slurry on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com