Uranium mine wastewater treatment method

A treatment method and wastewater technology, which is applied in mining wastewater treatment, biological water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problem of inability to effectively remove various pollutants in uranium mine wastewater, and achieve low treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

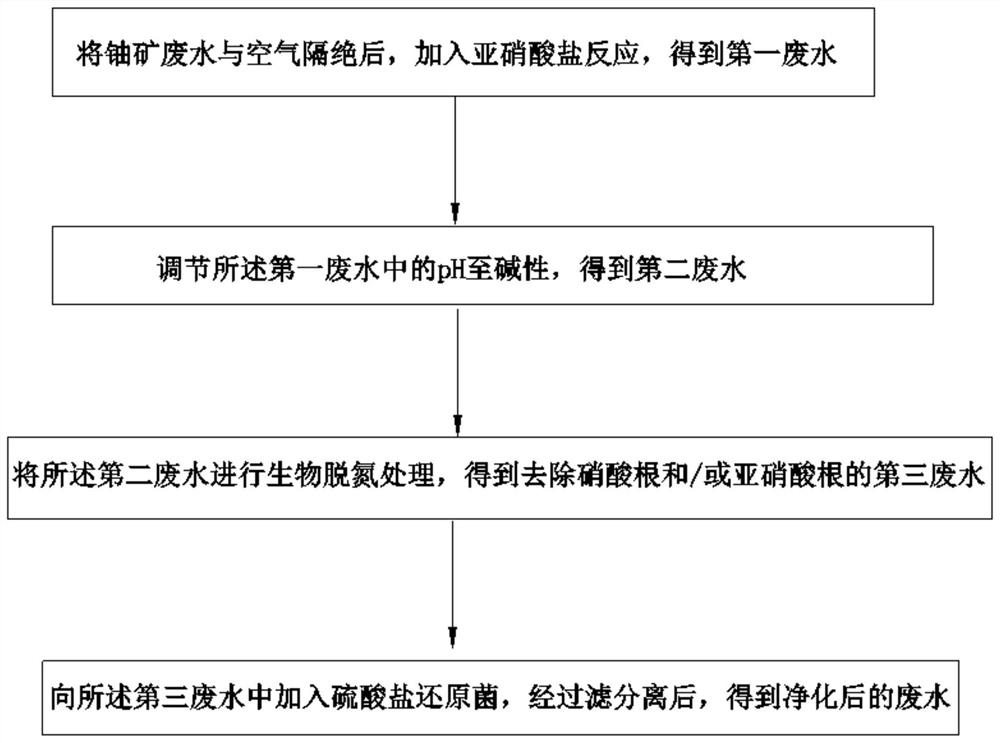

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a treatment method for uranium mine wastewater, wherein the concentration of dissolved oxygen in the wastewater is 5mg / L, 8mg / L Cu 2+ , 4mg / L Pb 2+ , 20mg / L UO 2 2+ , 10mg / L SO 4 2- , 8mg / L NO 3 - , the processing method includes the following steps:

[0052] 1) After isolating 10L of uranium mine wastewater from the air, add 3g of nitrite to react for 1 hour to obtain the first wastewater;

[0053] 2) adjusting the pH in the first wastewater to 7.0 by sodium hydroxide to obtain the second wastewater;

[0054] 3) The second wastewater is subjected to biological denitrification treatment, wherein 4 g of denitrifying bacteria are added for biological denitrification treatment, the temperature is 25° C., and the time is 2 hours, to obtain the third wastewater from which nitrate and nitrite are removed;

[0055] 4) Add 50 g of Desulfovibrio to the third wastewater, and after filtration and separation, purified wastewater is obtained.

[005...

Embodiment 2

[0058] This embodiment provides a treatment method for uranium mine wastewater, wherein the concentration of dissolved oxygen in the wastewater is 5mg / L, 8mg / L Cu 2+ , 4mg / L Pb 2+ , 20mg / L UO 2 2+ , 10mg / L SO 4 2- , 8mg / L NO 3 - , the processing method includes the following steps:

[0059] 1) After isolating 10L of uranium mine wastewater from the air, add 5g of nitrite to react for 1.5h to obtain the first wastewater;

[0060] 2) adjusting the pH in the first wastewater to 7.5 by sodium hydroxide to obtain the second wastewater;

[0061] 3) The second wastewater is subjected to biological denitrification treatment, wherein 5 g of denitrifying bacteria are added for biological denitrification treatment, the temperature is 35° C., and the time is 3 hours, to obtain the third wastewater from which nitrate and nitrite are removed;

[0062] 4) Add 80 g of Desulfovibrio to the third wastewater, and after filtration and separation, purified wastewater is obtained.

[0063]...

Embodiment 3

[0065] This embodiment provides a treatment method for uranium mine wastewater, wherein the concentration of dissolved oxygen in the wastewater is 5mg / L, 8mg / L Cu 2+ , 4mg / L Pb 2+ , 20mg / L UO 2 2+ , 10mg / L SO 4 2- , 8mg / L NO 3 - , the processing method includes the following steps:

[0066] 1) After isolating 10L of uranium mine wastewater from the air, add 10g of nitrite to react for 2 hours to obtain the first wastewater;

[0067] 2) adjusting the pH in the first wastewater to 8.0 by potassium hydroxide to obtain the second wastewater;

[0068] 3) The second wastewater is subjected to biological denitrification treatment, wherein 5 g of denitrifying bacteria are added for biological denitrification treatment, the temperature is 30° C., and the time is 6 hours, to obtain the third wastewater from which nitrate and nitrite are removed;

[0069] 4) Add 100 g of Desulfovibrio to the third wastewater, and after filtration and separation, purified wastewater is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com