Preparation method of epitaxial growth lanthanum nickelate and lanthanum strontium manganese oxide film

A thin-film and epitaxy technology, used in oxide conductors, non-metallic conductors, liquid chemical plating, etc., can solve problems such as difficult to control metal salt hydrolysis, harsh conditions, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

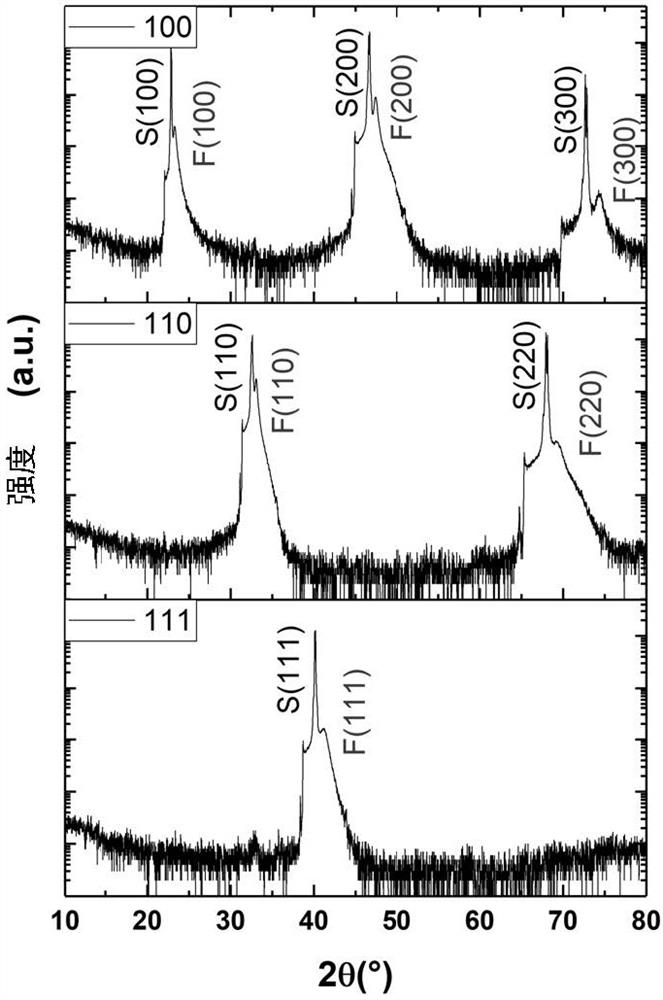

[0056] NeO 3 / SrTiO 3 (100) Film preparation

[0057] Specifically include the following steps:

[0058] (1) Weigh 0.584g of polyethyleneimine and 0.584g of ethylenediaminetetraacetic acid and dissolve them in 20mL of deionized water, and stir evenly;

[0059] (2) Add 0.316g of lanthanum acetate and 0.249g of nickel acetate and stir to dissolve in the above solution, and continue to stir for 10h at room temperature to obtain a precursor solution;

[0060] (3) Spin the precursor solution on SrTiO at a spin-coating speed of 5000r / min 3 (100) Spin the glue on the single crystal substrate for 30s to form a wet film;

[0061] (4) After the spin coating is completed, place the sample in the corundum ark, heat it slowly at a rate of 1°C / min in an air atmosphere, raise the temperature to 510°C, keep it for 2 hours, and then heat it up to 700°C at a rate of 5°C / min for rapid sintering 2h, cooled with the furnace, and finally produced LaNiO 3 / SrTiO 3 (100) film.

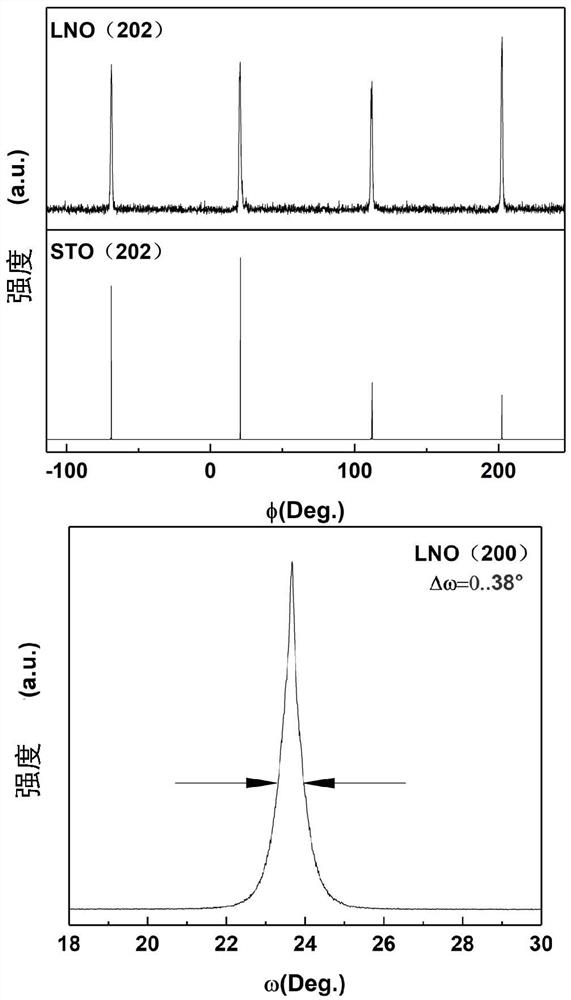

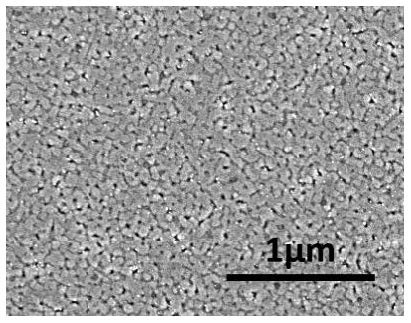

[0062] The ob...

Embodiment 2

[0070] Compared with Example 1, the difference is that in step (3), the single crystal substrate is (110) oriented SrTiO 3 , the structure of its XRD detection is as figure 1 , it can be seen that it grows with the substrate orientation. The resistivity change curve with temperature is as follows: Figure 4 .

Embodiment 3

[0072] Compared with Example 1, the difference is that in step (3), the single crystal substrate is (111) oriented SrTiO 3 , the structure of its XRD detection is as figure 1 , it can be seen that it grows with the substrate orientation. The resistivity change curve with temperature is as follows: Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com