Ni-NiO/C core-shell structure nano material electrocatalyst and preparation method thereof

A technology of electrocatalysts and nanomaterials, applied in the field of Ni-NiO/C core-shell structure nanomaterial electrocatalysts and their preparation, can solve the problems of low hydrogen evolution catalytic efficiency, achieve high catalytic activity, good product appearance, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A preparation method of the Ni-NiO / C core-shell structure nano material electrocatalyst, comprising the following steps:

[0049] (1) Dissolving nickel chloride hexahydrate in distilled water to form a first solution; every 10 mL of distilled water corresponds to 0.7-0.9 g of nickel chloride hexahydrate.

[0050] (2) aminoacetic acid and isopropanol are added in the above-mentioned first solution, form the second solution; Every 30mL isopropanol solution corresponds to 0.3-0.5g aminoacetic acid; The volume ratio of isopropanol solution and the distilled water of step 1 is 2-2.2:1.

[0051] (3) Stir the above second solution magnetically for 10-20min to form a suspension, transfer the suspension into a container, cool to room temperature after gradient heating reaction, and obtain a light green precipitate; gradient heating includes: the first heating stage, The reaction temperature is 100-160°C, and the reaction time is 2-2.5 hours; the second heating stage is 180-200°...

Embodiment 1

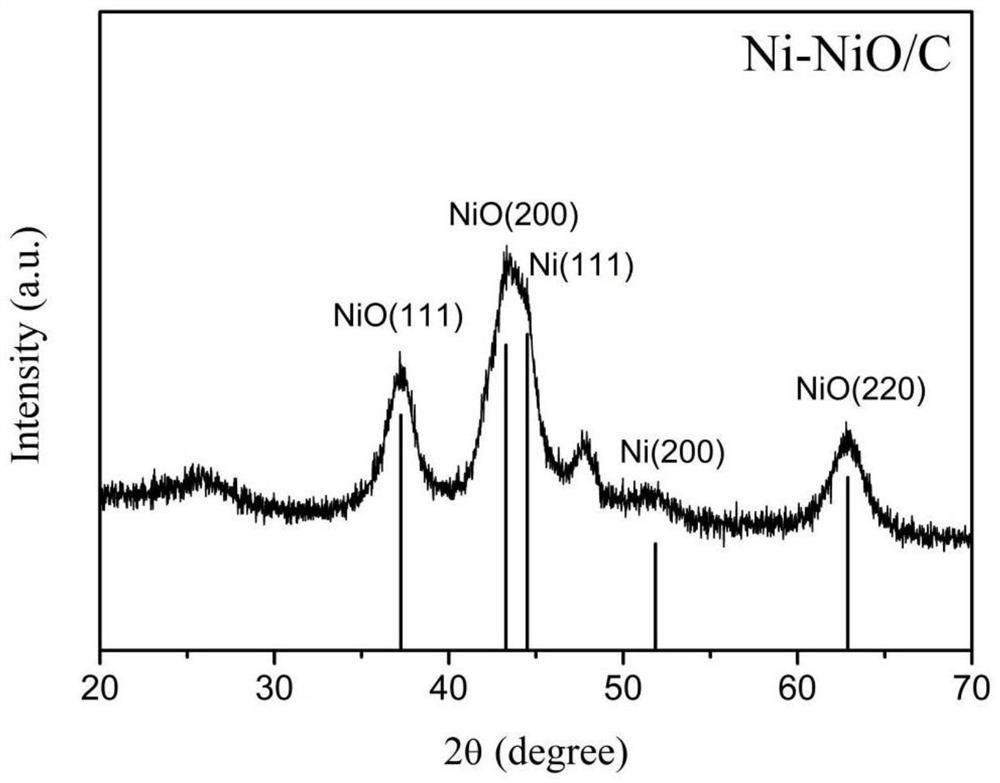

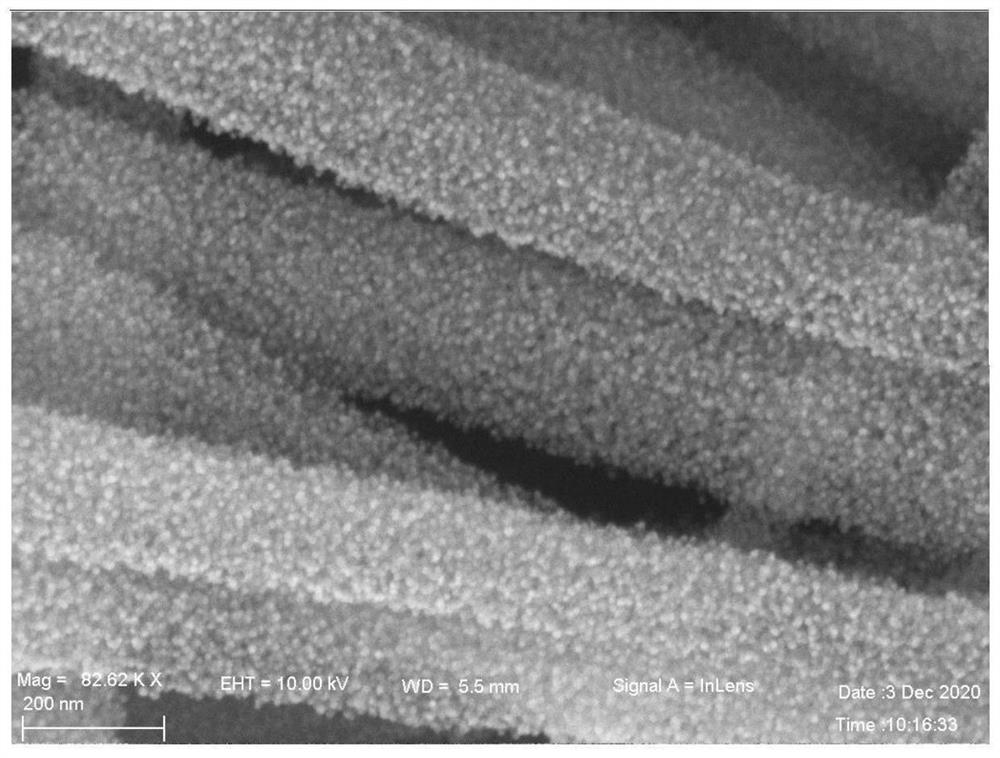

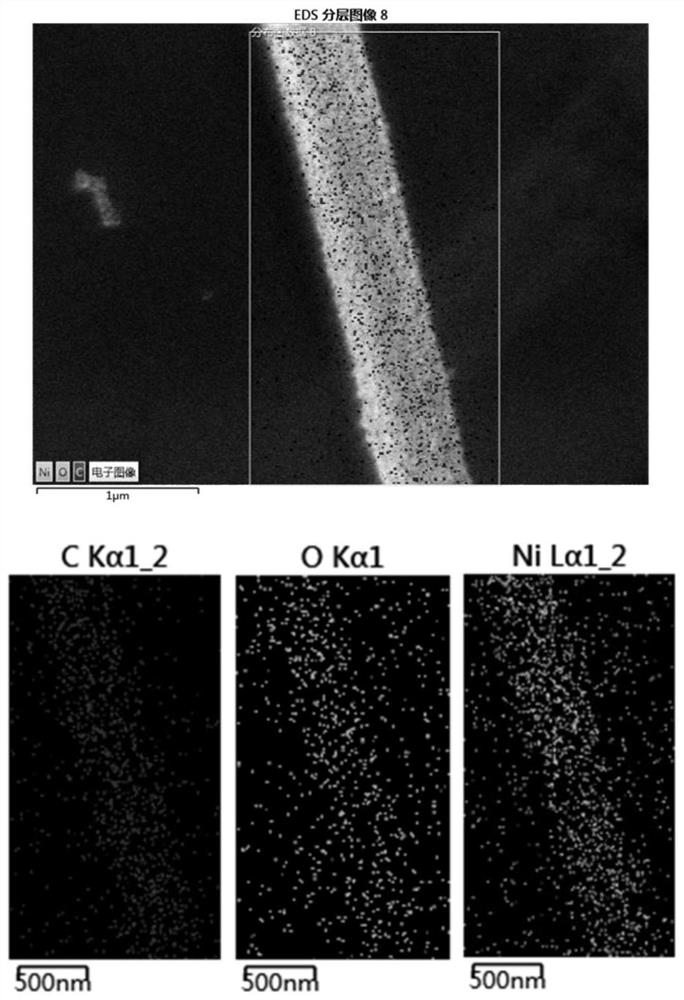

[0056] A Ni-NiO / C core-shell nanomaterial electrocatalyst, the electrocatalyst is a core-shell structure obtained by compounding and calcining nickel chloride hexahydrate and ammonia acetic acid.

[0057] A preparation method of the Ni-NiO / C core-shell structure nano material electrocatalyst, comprising the following steps:

[0058] (1) Dissolving nickel chloride hexahydrate in distilled water to form a first solution; every 10 mL of distilled water corresponds to 0.8 g of nickel chloride hexahydrate.

[0059] (2) Add aminoacetic acid and isopropanol to the above-mentioned first solution to form a second solution; every 30 mL of isopropanol solution corresponds to 0.4 g of aminoacetic acid; the volume ratio of the isopropanol solution to the distilled water in step 1 is 2.1: 1.

[0060] (3) Stir the above second solution magnetically for 10-20min to form a suspension, transfer the suspension into a container, cool to room temperature after gradient heating reaction, and obtai...

Embodiment 2

[0065] A Ni-NiO / C core-shell nanomaterial electrocatalyst, the electrocatalyst is a core-shell structure obtained by compounding and calcining nickel chloride hexahydrate and ammonia acetic acid.

[0066] A preparation method of the Ni-NiO / C core-shell structure nano material electrocatalyst, comprising the following steps:

[0067] (1) Dissolving nickel chloride hexahydrate in distilled water to form a first solution; every 10 mL of distilled water corresponds to 0.7 g of nickel chloride hexahydrate.

[0068] (2) Add aminoacetic acid and isopropanol to the above-mentioned first solution to form a second solution; every 30mL isopropanol solution corresponds to 0.3g aminoacetic acid; the volume ratio of the isopropanol solution to the distilled water in step 1 is 2: 1.

[0069] (3) Magnetically stir the above-mentioned second solution for 20 minutes to form a suspension, transfer the suspension to a container, cool to room temperature after the gradient heating reaction, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com