In-situ photocuring antibacterial bone defect repair gel and preparation method thereof

A light-curing, bacterial-bone technology, used in medical science, prosthesis, tissue regeneration, etc., to promote proliferation and osteogenic differentiation, and prevent infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

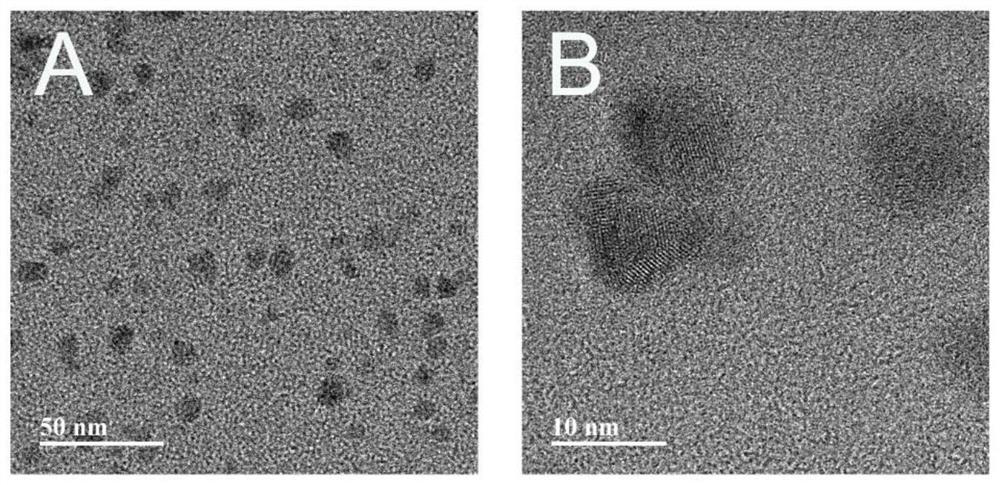

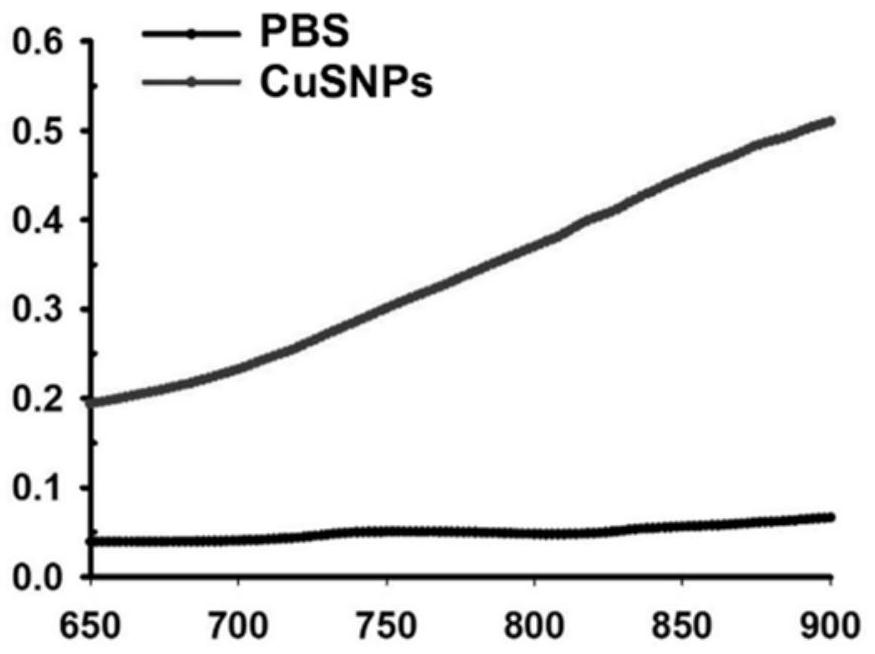

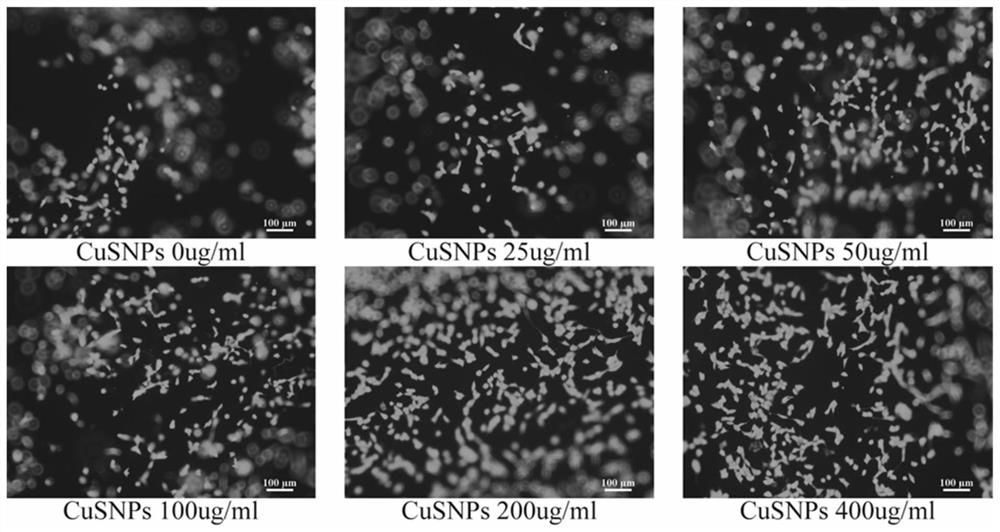

[0026] An in situ photocurable antibacterial bone defect repair gel, including copper sulfide nanoparticles (CuSNPs), 10% (w / w) GelMA photocurable hydrogel.

[0027] The preparation method of the above-mentioned bone defect repair gel comprises the following steps:

[0028] S1: Put copper acetate and chitosan (molecular weight 50,000-190,000Da, 75-85% deacetylation) in a three-necked flask, add 50mL dilute acetic acid solution, and stir vigorously for 24 hours under nitrogen protection;

[0029] S2: Weigh sodium sulfide, dissolve it in 1mL deionized water, add it dropwise to the flask, and continue stirring for 30 minutes;

[0030] S3: Connect the condenser, keep stirring, heat up to the crystal growth temperature at a rate of 5°C per minute, and keep warm for 30 minutes, then dialyze the solution in deionized water for 3-5 days to obtain CuSNPs;

[0031] S4: Take 100mL of CuSNPs (1.8mg / mL) and add it into a glass flask after sonication, and add 3mL of methacrylic anhydride d...

Embodiment 2

[0040] An in situ photocurable antibacterial bone defect repair gel, including methacrylylated modified CuSNPs, 5% (w / w) GelMA photocurable hydrogel.

[0041] The preparation method of the above-mentioned bone defect repair gel comprises the following steps:

[0042] S1: Put copper acetate and chitosan (molecular weight 50,000-190,000Da, 75-85% deacetylation) in a three-necked flask, add 50mL dilute acetic acid solution, and stir vigorously for 24 hours under nitrogen protection;

[0043] S2: Weigh sodium sulfide, dissolve it in 1mL deionized water, add it dropwise to the flask, and continue stirring for 30 minutes;

[0044] S3: Connect the condenser, keep stirring, heat up to the crystal growth temperature at a rate of 5°C per minute, and keep warm for 30 minutes, then dialyze the solution in deionized water for 3-5 days to obtain CuSNPs;

[0045] S4: Take 100mL of CuSNPs (1.8mg / mL) and add it into a glass flask after sonication, and add 3mL of methacrylic anhydride dropwise...

Embodiment 3

[0052] An in situ photocurable antibacterial bone defect repair gel, including methacrylylated modified CuSNPs, 7% (w / w) GelMA photocurable hydrogel.

[0053] The preparation method of the above-mentioned bone defect repair gel comprises the following steps:

[0054] S1: Put copper acetate and chitosan (molecular weight 50,000-190,000Da, 75-85% deacetylation) in a three-necked flask, add 50mL dilute acetic acid solution, and stir vigorously for 24 hours under nitrogen protection;

[0055] S2: Weigh sodium sulfide, dissolve it in 1mL deionized water, add it dropwise to the flask, and continue stirring for 30 minutes;

[0056] S3: Connect the condenser, keep stirring, heat up to the crystal growth temperature at a rate of 5°C per minute, and keep warm for 120 minutes, then dialyze the solution in deionized water for 3-5 days to obtain CuSNPs;

[0057] S4: Take 100mL of CuSNPs (1.5mg / mL) and add it into a glass flask after sonication, and add 3mL of methacrylic anhydride dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com