Adsorbent for industrial sewage treatment and preparation method thereof

A technology of industrial sewage and adsorbent, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of difficult water treatment to meet the reuse requirements, limited ammonia nitrogen adsorption effect, and activated carbon regeneration Low efficiency and other problems, to achieve good adsorption and sedimentation effect, excellent adsorption treatment effect, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

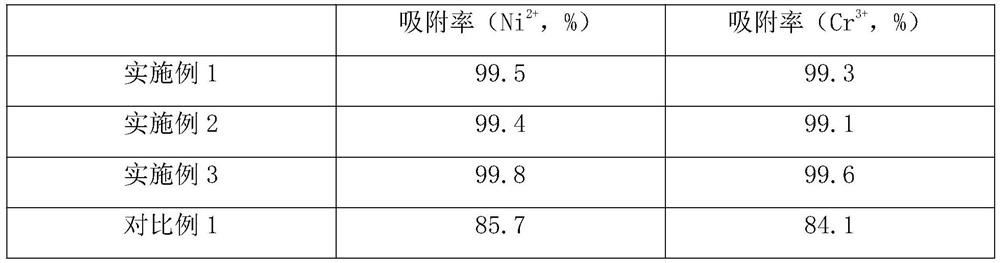

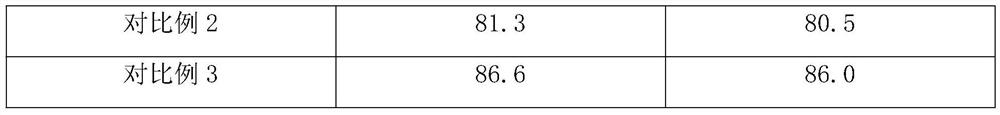

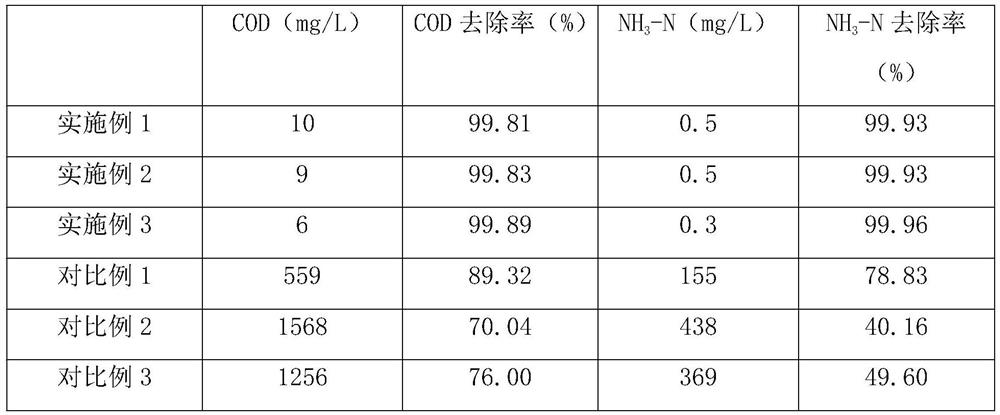

Examples

Embodiment 1

[0026] A method for preparing an adsorbent for industrial sewage treatment. Firstly, compound halloysite nanotubes are modified with N-(β-aminoethyl)-γ-aminopropyltriethoxysilane to obtain modified Å Halloysite nanotubes; then modify the edible fungus residues with epichlorohydrin to obtain epoxidized bacteria residues; then mix the modified halloysite nanotubes with epoxidized bacteria residues, and use starch to branch, to obtain an intermediate product; finally, the intermediate product is mixed with vinylidene fluoride and 2-acrylamide-2-methylpropanesulfonic acid and polymerized to obtain the aforementioned adsorbent for industrial sewage treatment; wherein, the The composite halloysite nanotube is obtained by compounding the halloysite nanotube and zirconium nitrate solution as raw materials.

[0027] The preparation method of the modified halloysite nanotube is as follows: first, 1kg N-(β-aminoethyl)-γ-aminopropyltriethoxysilane is ultrasonically dispersed in 5kg toluen...

Embodiment 2

[0037] A method for preparing an adsorbent for industrial sewage treatment. Firstly, compound halloysite nanotubes are modified with N-(β-aminoethyl)-γ-aminopropyltriethoxysilane to obtain modified Å Halloysite nanotubes; then modify the edible fungus residues with epichlorohydrin to obtain epoxidized bacteria residues; then mix the modified halloysite nanotubes with epoxidized bacteria residues, and use starch to branch, to obtain an intermediate product; finally, the intermediate product is mixed with vinylidene fluoride and 2-acrylamide-2-methylpropanesulfonic acid and polymerized to obtain the aforementioned adsorbent for industrial sewage treatment; wherein, the The composite halloysite nanotube is obtained by compounding the halloysite nanotube and zirconium nitrate solution as raw materials.

[0038] The preparation method of the modified halloysite nanotube is as follows: first, 1kg N-(β-aminoethyl)-γ-aminopropyltriethoxysilane is ultrasonically dispersed in 7kg toluen...

Embodiment 3

[0048] A method for preparing an adsorbent for industrial sewage treatment. Firstly, compound halloysite nanotubes are modified with N-(β-aminoethyl)-γ-aminopropyltriethoxysilane to obtain modified Å Halloysite nanotubes; then modify the edible fungus residues with epichlorohydrin to obtain epoxidized bacteria residues; then mix the modified halloysite nanotubes with epoxidized bacteria residues, and use starch to branch, to obtain an intermediate product; finally, the intermediate product is mixed with vinylidene fluoride and 2-acrylamide-2-methylpropanesulfonic acid and polymerized to obtain the aforementioned adsorbent for industrial sewage treatment; wherein, the The composite halloysite nanotube is obtained by compounding the halloysite nanotube and zirconium nitrate solution as raw materials.

[0049] The preparation method of the modified halloysite nanotube is as follows: first, 1kg N-(β-aminoethyl)-γ-aminopropyltriethoxysilane is ultrasonically dispersed in 6kg toluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com