Preparation method for controlling thickness of colloidal crystal film by adjusting humidity

A film thickness and humidity control technology, which is applied to the device for coating liquid on the surface, silicon dioxide, silicon oxide, etc., can solve the problems of different environmental humidity and lack of film materials, and achieve a large humidity range and convenient observation , thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

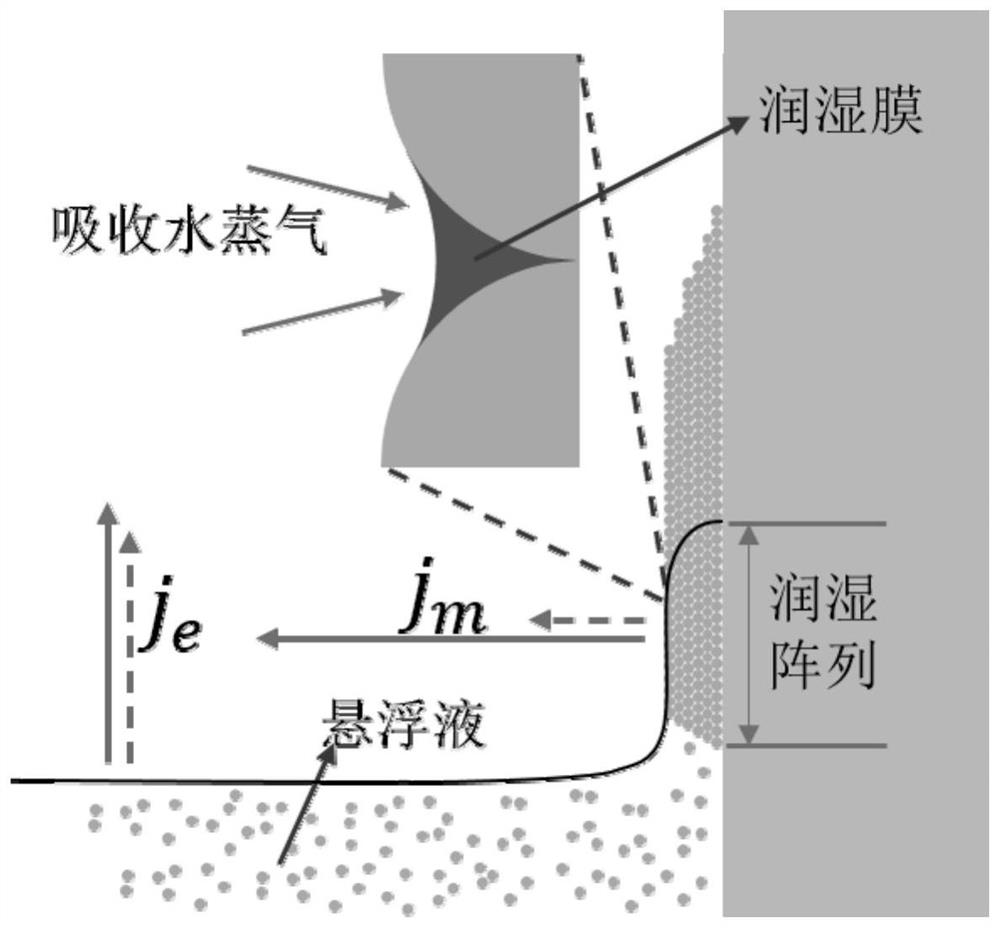

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of low-thickness silicon dioxide colloidal crystal thin film on single crystal silicon wafer

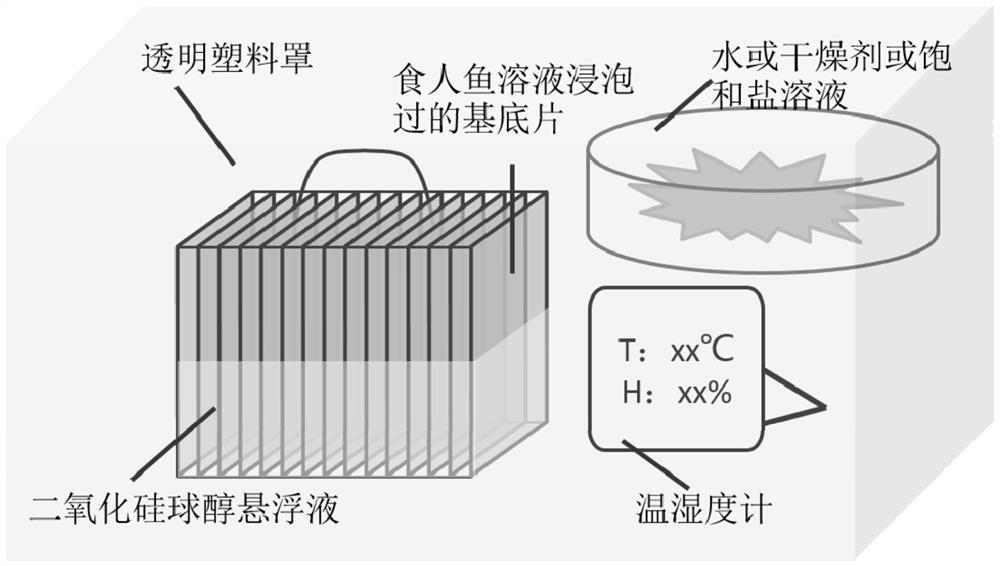

[0026] The growth device for preparing silica colloidal crystal thin films is as follows: figure 2 As shown, (1) Add 300mL pure water to the beaker, place the beaker filled with water in a closed transparent plastic box, and a hygrometer is installed in the plastic box, cover the lid, and observe the hygrometer in the plastic box after about 12 hours. The relative humidity in the plastic box reaches 99%.

[0027] (2) Use ethanol as a solvent to configure a 190nm silicon dioxide alcohol suspension with a mass concentration of 5g / L and put it into a dyeing vat, and use the monocrystalline silicon wafer soaked in piranha solution as a substrate, and insert it vertically into the container. In a staining jar with an ethanol suspension of silica.

[0028] (3) Put the dyeing vat containing the silicon dioxide ethanol suspension into the transparent plastic b...

Embodiment 2

[0030] Example 2 Preparation of high-thickness silicon dioxide colloidal crystal thin film on glass sheet

[0031] (1) Add 400g of anhydrous calcium chloride to the beaker, place the beaker in an airtight transparent plastic box, a hygrometer is housed in the plastic box, cover the lid, and observe the hygrometer in the plastic box after about 24 hours. The relative humidity reaches 5%.

[0032] (2) take ethanol as the solvent configuration mass concentration and be that the 190nm silicon dioxide alcohol suspension of 15g / L is packed in the staining vat, handle the glass slide glass as the base sheet through soaking in piranha solution, insert it vertically into the Silica alcohol suspension in the staining jar.

[0033] (3) Put the staining vat equipped with the silica alcohol suspension into the transparent plastic box in step (1), and take out the glass slide after 7 days.

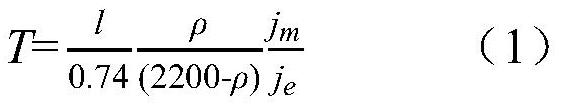

[0034] Measure the thickness of the glass sheet obtained in the above step (3) by "interferometry"...

Embodiment 3

[0035] Example 3 Preparation of high-thickness silica colloidal crystal thin film on glass sheet

[0036] (1) Add 400g of anhydrous calcium chloride to the beaker, place the beaker in an airtight transparent plastic box, a hygrometer is housed in the plastic box, cover the lid, and observe the hygrometer in the plastic box after about 24 hours. The relative humidity reaches 5%.

[0037] (2) Take ethanol as the solvent configuration mass concentration and be that the 100nm silicon dioxide alcohol suspension of 15g / L is packed in the staining vat, handle the glass slide as the substrate through soaking in the piranha solution, insert it vertically into the Silica alcohol suspension in the staining jar. After measuring the length of the colloidal crystal film and dividing it by the assembly time (7 days), the assembly speed can be calculated to be about 1.8mm / day.

[0038] (3) Put the staining vat equipped with the silica alcohol suspension into the transparent plastic box in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com