Polyurethane waterproof coating and application thereof

A polyurethane waterproof, polyurethane prepolymer technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as flow, and achieve the effects of mild reaction, good thixotropy, and regular and dense molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

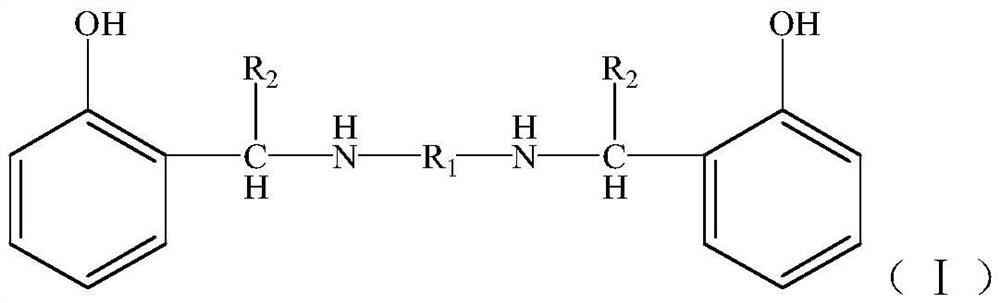

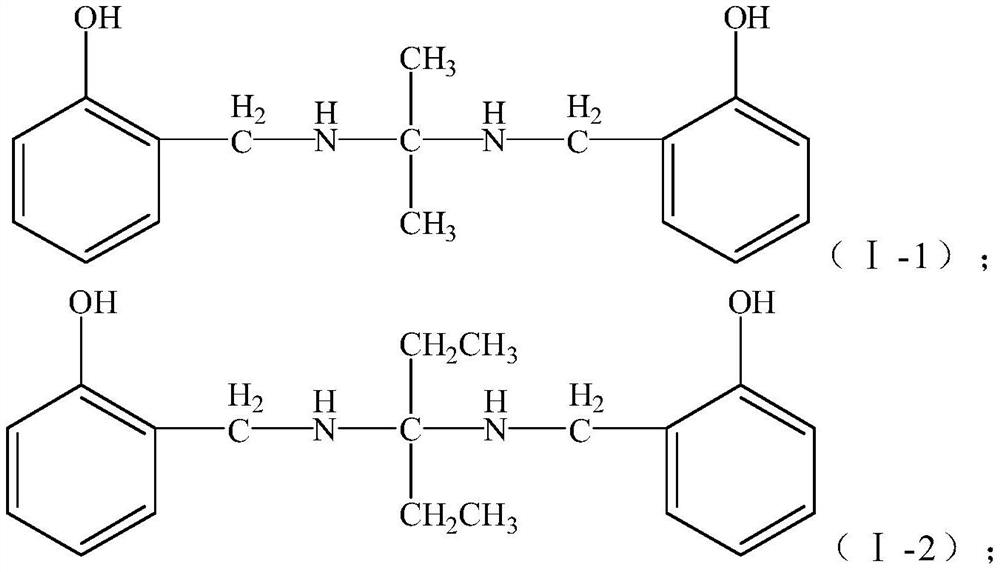

[0058] This example provides the secondary amine compound of structure shown in a kind of formula (I-1):

[0059]

[0060] Its preparation method comprises the following steps:

[0061] (a) make phenol (1mol), mass fraction be that 37% formaldehyde aqueous solution (containing formaldehyde 2mol), alkaline earth metal magnesium type catalyst 0.05mol (being made of magnesium hydroxide and magnesium oxide that feed molar ratio is 1: 1) mixes, Raise the temperature to 60°C and react for 1h;

[0062] (b) in the reaction solution after step (a) reaction, add the isopropyl diamine (H) to be reacted 2 N-C(CH 3 ) 2 -NH 2 , 0.5mol), mixed, heated up to 120°C, reacted for 4h, then vacuum dehydrated, controlled moisture content below 500ppm, until a transparent viscous liquid product was obtained, and the compound shown in the formula (I-1) was prepared.

Embodiment 2

[0064] This example provides the secondary amine compound of structure shown in a kind of formula (I-2):

[0065]

[0066] Its preparation method comprises the following steps:

[0067] (a) make phenol (1mol), mass fraction be that 37% formaldehyde aqueous solution (containing formaldehyde 2mol), alkaline earth metal magnesium type catalyst 0.05mol (being made of magnesium hydroxide and magnesium oxide that feed molar ratio is 1: 1) mixes, Raise the temperature to 60°C and react for 1h;

[0068] (b) add 3-diaminopentane (H) to be reacted in the reaction solution after step (a) reaction 2 N-C (CH 2 CH 3 ) 2 -NH 2 , 0.5mol), mixed, heated up to 120°C, reacted for 4 hours, then vacuum dehydrated to control the water content below 500ppm until a transparent viscous liquid product was obtained, and the compound represented by the formula (I-1) was prepared.

Embodiment 3

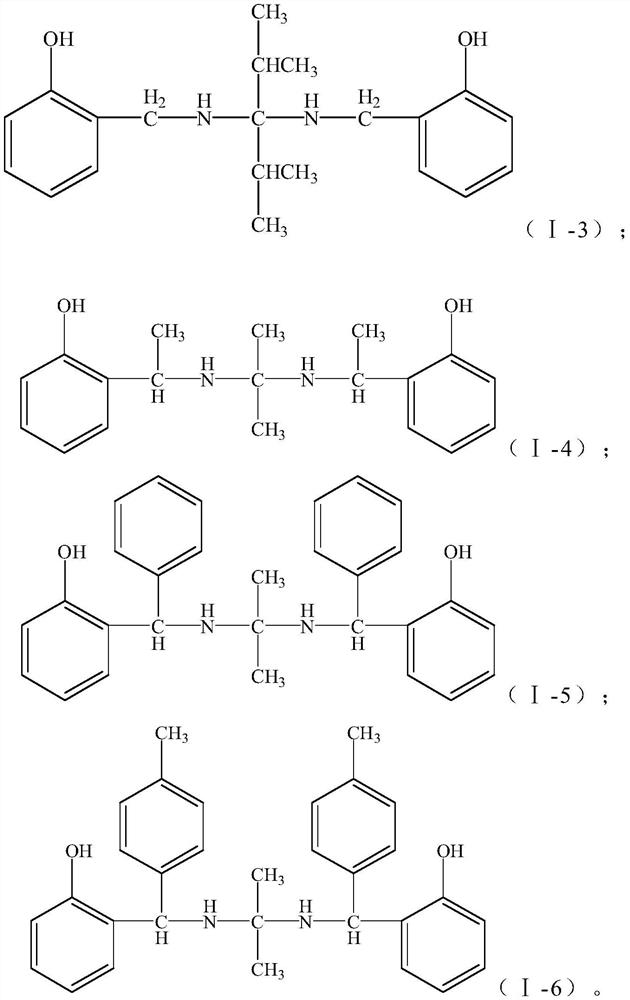

[0070] This example provides the secondary amine compound of structure shown in a kind of formula (I-5):

[0071]

[0072] Its preparation method comprises the following steps:

[0073] (a) Mix phenol (1mol), benzaldehyde (2mol), and 0.05mol of an alkaline earth metal magnesium catalyst (consisting of magnesium hydroxide and magnesium oxide with a feed molar ratio of 1:1), heat up to 80°C, and react for 1h;

[0074] (b) in the reaction solution after step (a) reaction, add the isopropyl diamine (H) to be reacted 2 N-C(CH 3 ) 2 -NH 2 , 0.5mol), mixed, heated up to 120°C, reacted for 4h, then vacuum dehydrated, controlled moisture content below 500ppm, until a transparent viscous liquid product was obtained, and the compound shown in the formula (I-5) was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com