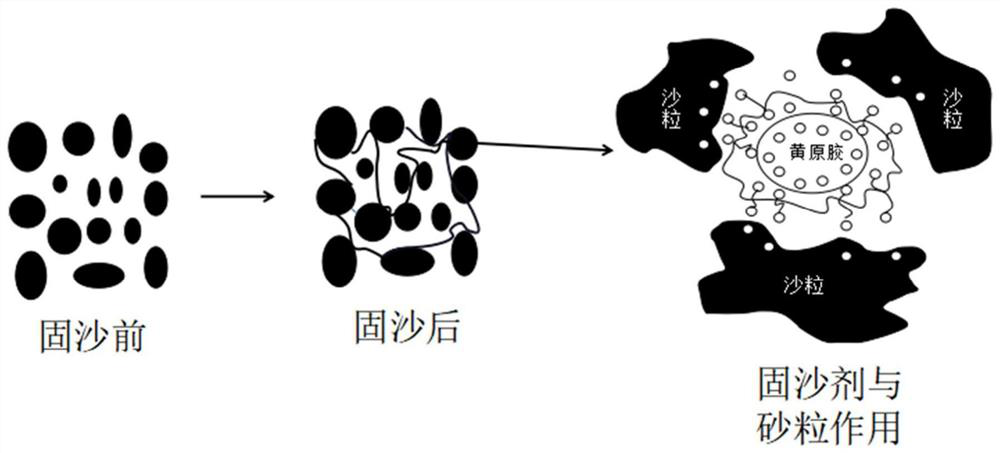

Sand solidification agent prepared from xanthan gum in fracturing flow-back fluid of oil and gas field as well as preparation method and application of sand solidification agent

A fracturing flowback fluid, oil and gas field technology, applied in application, chemical instruments and methods, other chemical processes, etc., can solve the problems of intractable fracturing flowback fluid, achieve wide applicability and innovation, and solve land desertification , the effect of large promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take oil and gas field fracturing flowback fluid into a three-necked flask, add 0.5wt% demulsification flocculant, stir for 15 minutes, and filter after standing for 2 hours, in which polyaluminum chloride and polymethacryloyloxyethyl trimethyl chloride The mass ratio of ammonium is 1:2. Then add 2wt% of 30% hydrogen peroxide aqueous solution and ferrous phosphate with 0.4 times the mass of hydrogen peroxide, stir and react for 3 hours to obtain pretreated oil and gas field fracturing flowback fluid. The sand-fixing agent is obtained by adding 3wt% of humic acid and 2wt% of xanthan gum to the pretreated oil and gas field fracturing flowback fluid.

Embodiment 2

[0026] Take oil and gas field fracturing flowback fluid into a three-necked flask, add 1.0wt% demulsification flocculant, stir for 25 minutes, and filter after standing for 3 hours, in which polyaluminum chloride and polymethacryloyloxyethyl trimethyl chloride The mass ratio of ammonium is 1:3. Then add 4wt% 30% hydrogen peroxide aqueous solution and ferrous phosphate 0.8 times the mass of hydrogen peroxide, and stir for 4 hours to obtain pretreated oil and gas field fracturing flowback fluid. The sand-fixing agent is obtained by adding 3wt% of humic acid and 2wt% of xanthan gum to the pretreated oil and gas field fracturing flowback fluid.

Embodiment 3

[0028] Take oil and gas field fracturing flowback fluid into a three-necked flask, add 0.8wt% demulsification flocculant, stir for 20 minutes, and filter after standing for 2.5 hours, in which polyaluminum chloride and polymethacryloyloxyethyl trimethyl chloride The mass ratio of ammonium chloride is 1:3. Then add 3wt% 30% hydrogen peroxide aqueous solution and ferrous phosphate with 0.6 times the mass of hydrogen peroxide, stir and react for 3 hours to obtain pretreated oil and gas field fracturing flowback fluid. The sand-fixing agent is obtained by adding 2.5wt% humic acid and 0.7wt% xanthan gum to the pretreated oil and gas field fracturing flowback fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com