Method for preparing mineral wool through ardealite high-temperature melting and mineral wool

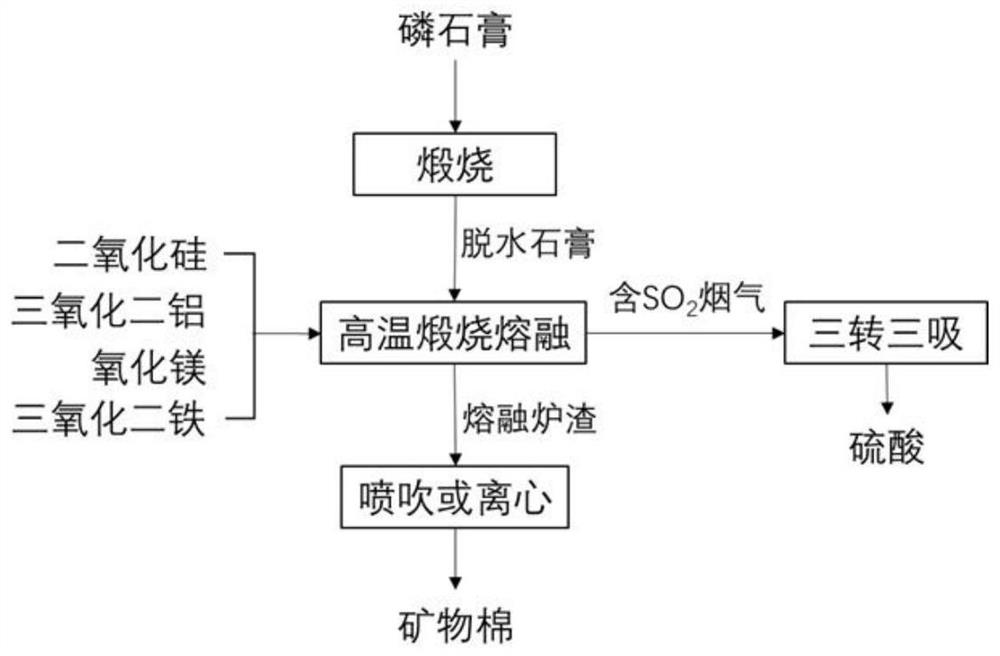

A high-temperature melting, phosphogypsum technology, applied in the field of phosphogypsum resource utilization, can solve the problems of glass phase structure, comprehensive utilization and disposal rate of less than 40%, and difficult utilization of phosphogypsum, so as to solve ecological and environmental problems and achieve benign health. The effect of developing and alleviating external dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) 6500 g of dehydrated phosphogypsum and 1800 g of silicon dioxide, 900 g of aluminum oxide, 300 g of magnesium oxide, 100 g of ferric oxide are mixed to obtain a mixture (in parts by weight, 65 parts of dehydrated phosphogypsum, 18 parts of silica parts, 9 parts of aluminum oxide, 3 parts of magnesium oxide, and 1 part of ferric oxide); wherein the preparation of dehydrated phosphogypsum is: placing the dihydrate gypsum in a Luoyang Juxing kiln at 250 °C for 10 min;

[0049] (2) send the mixture obtained in step (1) into Xingding kiln, then be heated to 1600 ℃ with a heating rate of 25 ℃ / min for 40min and carry out high temperature melting to obtain slag; the gained contains SO 2 The flue gas obtained by the three-turn three-suction process produces sulfuric acid;

[0050] (3) After the molten slag obtained in step (2) flows out from the bottom of the furnace, it is transported to the roller head of a four-roll centrifuge (SG~200*75, Nanjing Yalong) through a diversi...

Embodiment 2

[0053] (1) 5700 g of dehydrated phosphogypsum and 1350 g of silicon dioxide, 1000 g of aluminum oxide, 600 g of magnesium oxide, 60 g of ferric oxide were mixed to obtain a mixture (in parts by weight, 57 parts of dehydrated phosphogypsum, 13.5 parts of silica parts, 10 parts of aluminum oxide, 6 parts of magnesium oxide, and 0.6 parts of iron oxide); wherein the preparation of dehydrated phosphogypsum is: placing the dihydrate gypsum in a GWL-LB box furnace at 200°C for 20min calcination;

[0054] (2) send the mixture obtained in step (1) into XD~10L stirring frit furnace, then be heated to 1450 ℃ heat preservation treatment 100min with the heating rate of 20 ℃ / min and carry out high temperature melting, obtain slag; the gained contains SO 2 The flue gas obtained by the three-turn three-suction process produces sulfuric acid;

[0055] (3) the slag obtained in step (2) flows out from the bottom of the furnace to obtain mineral wool with an average diameter of 3.7 μm through hi...

Embodiment 3

[0057] (1) mix 6000 g of dehydrated phosphogypsum and 1000 g of silicon dioxide, 1200 g of aluminum oxide, 600 g of magnesium oxide, 60 g of ferric oxide to obtain a mixture (in parts by weight, 60 parts of dehydrated phosphogypsum, 10 parts of silica parts, 12 parts of aluminum oxide, 6 parts of magnesium oxide, and 0.6 parts of iron oxide); wherein, the preparation of dehydrated phosphogypsum is as follows: gypsum dihydrate is placed in a GWL-LB box furnace for calcination at 190° C. for 10 min;

[0058] (2) the mixture obtained in step (1) is sent into XD~10L stirring frit furnace, then the temperature is raised to 1500°C for 90min with a heating rate of 30°C / min to carry out high temperature melting to obtain slag; the gained contains SO 2 The flue gas obtained by the three-turn three-suction process produces sulfuric acid;

[0059] (3) After the molten slag obtained in step (2) flows out from the bottom of the melting furnace, it is transported to the roller head of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com