Multifunctional vegetable oil-based acrylate as well as preparation method and application thereof

An oil-based acrylate and multi-functionality technology, which is applied in the fields of sulfide preparation, organic chemistry, coating, etc., can solve the problems of petroleum-based UV curing coatings that are not easy to degrade, environmental pollution, ecological environment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of polyfunctional castor oil-based acrylate, comprising the steps of:

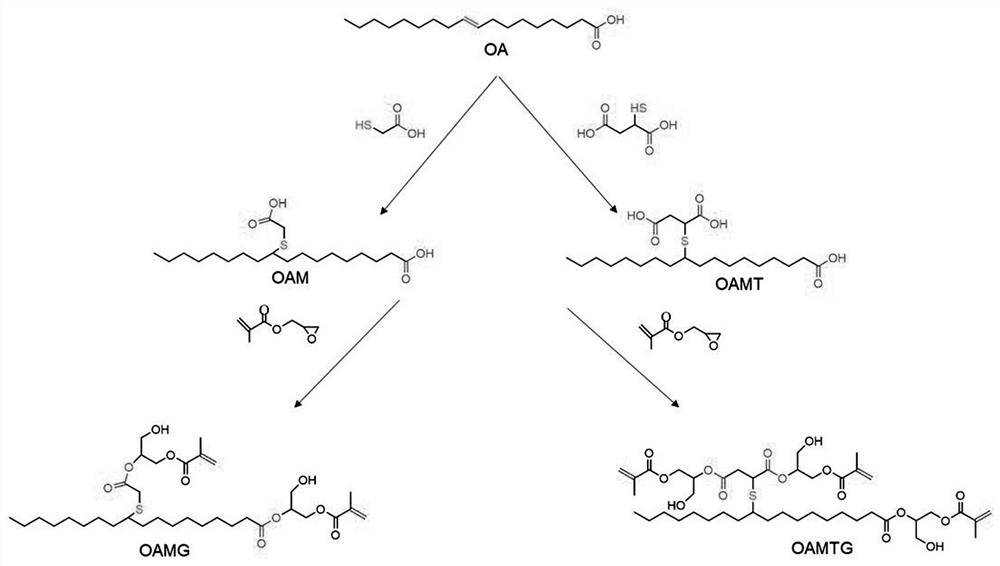

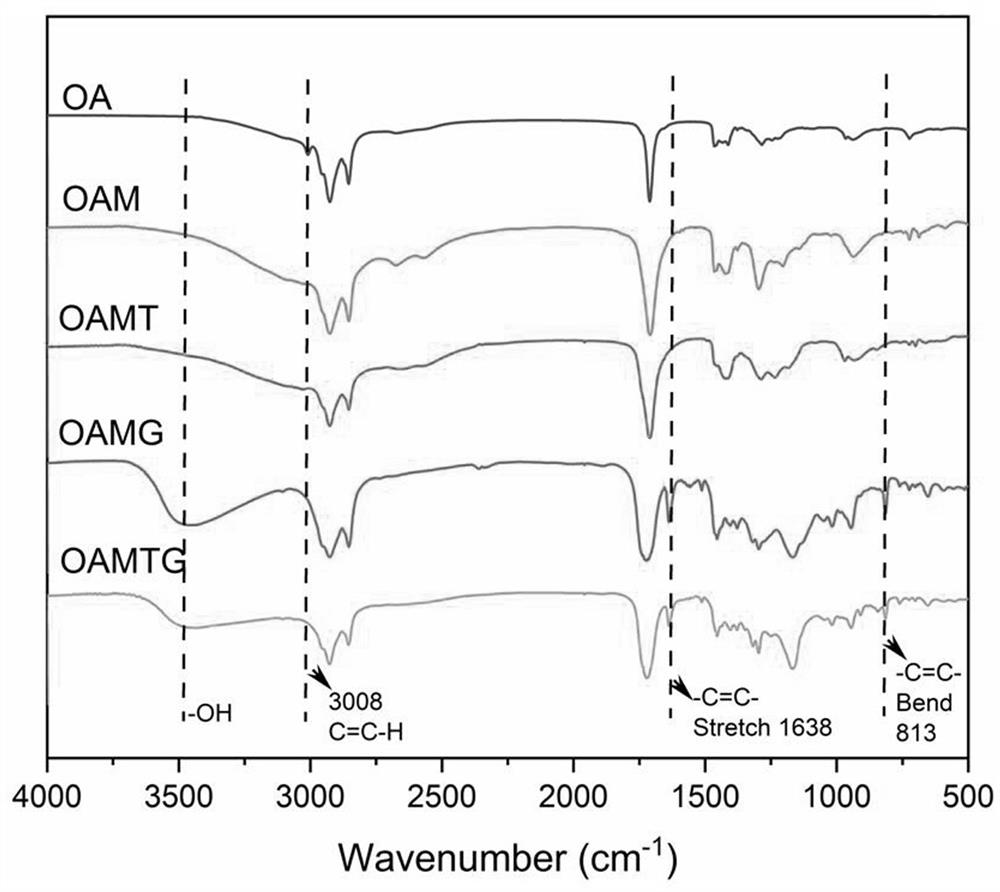

[0049] (1) Add oleic acid (10.00g), thioglycolic acid (3.80g, purity 90%) and 5% photoinitiator (2-hydroxy-2-methanol) in a quartz test tube with a magnetic rotor Propiophenone 0.69g), placed in a photochemical reaction apparatus, and irradiated with ultraviolet light with a wavelength of 365nm at room temperature for 6h to obtain oleic acid-based dicarboxylic acid. The molar ratio of oleic acid to thioglycolic acid is 1:1.05.

[0050] (2) Add oleic acid (10.00g), thiomalic acid (5.70g, purity 98%) and photoinitiator (2-hydroxy-2 - methyl propiophenone 0.79g), placed in a photochemical reaction apparatus, and irradiated with ultraviolet light with a wavelength of 365nm at room temperature for 6h to obtain oleic acid-based tricarboxylic acid. The molar ratio of oleic acid to thioglycolic acid is 1:1.05.

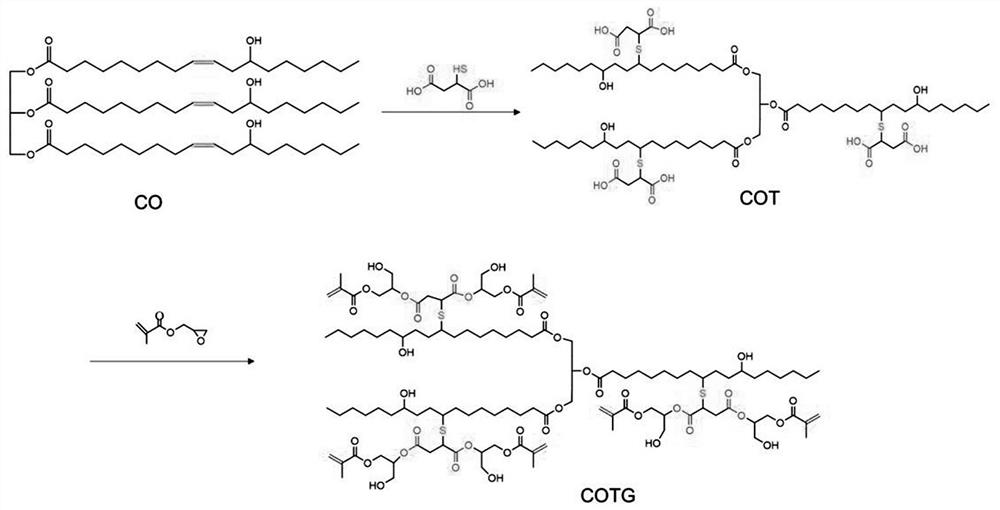

[0051] (3) Add castor oil (10.00g), thiomalic acid (5.01g, purity 98%) a...

Embodiment 2

[0057] A preparation method of multifunctional castor oil-based acrylate, which is the same as Example 1 except for the following steps: castor oil-based hexavalent acrylate (9.00g), oleic acid-based dibasic acrylate (1.00g) and photoinitiated The prepolymer (0.30g) was placed in a 20mL glass bottle with a magnetic rotor and stirred evenly, and then the prepolymer was spread on a glass plate with a 500μm applicator, and irradiated for 30s under a UV-LED light source with a wavelength of 365nm to obtain Light curing film. The mass ratio of the castor oil-based six-basic acrylate and oleic acid-based tribasic acrylate is 9:1, and the content of the photoinitiator is the total amount of castor oil-based hexa-basic acrylate and oleic acid-based dibasic acrylate 3wt%.

Embodiment 3

[0059] A preparation method of multifunctional castor oil-based acrylate is the same as Example 2 except for the following steps: the mass ratio of the castor oil-based hexavalent acrylate to oleic acid-based diacrylate is 8:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com