Disposable PVC glove and production process thereof

A production process, one-time technology, applied in gloves, clothing, protective clothing, etc., can solve the problems of PVC gloves with large thickness, low tensile strength and easy deformation, low elongation rate and easy damage, etc., to achieve good color performance and durability. The effect of heat resistance, low production cost and fast defoaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

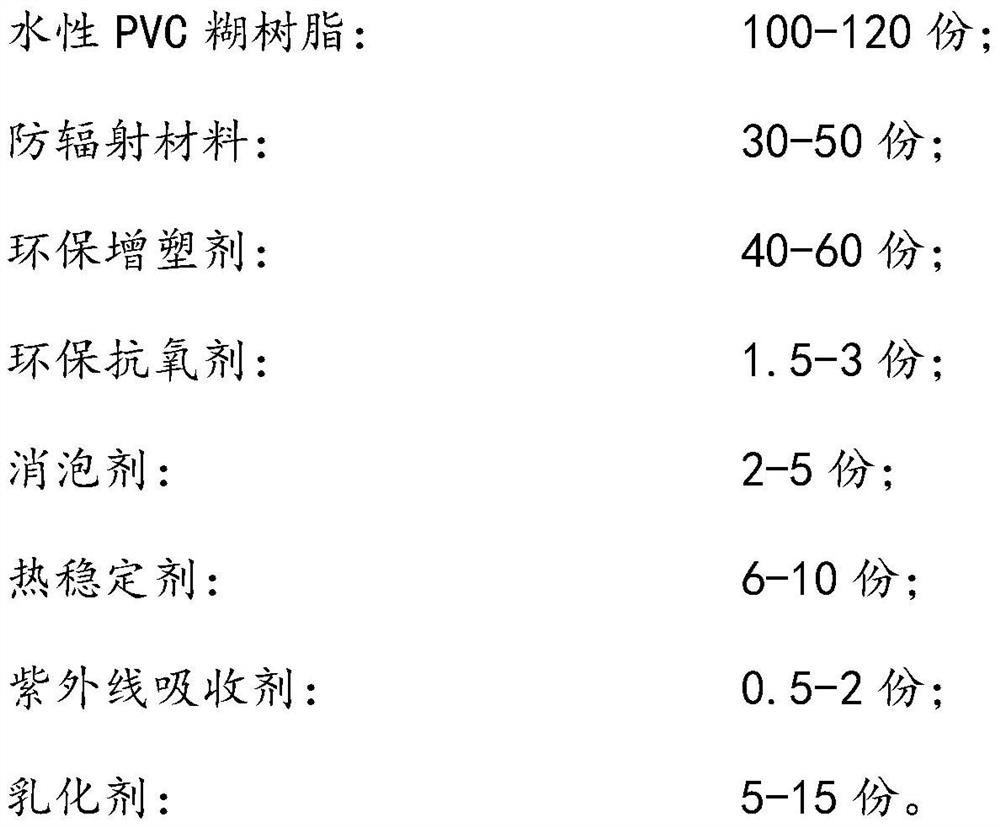

[0028] In a preferred embodiment of the present invention, disposable PVC gloves comprise the raw material of following weight fraction:

[0029]

[0030] It is worth noting that the water content of the water-based PVC paste resin in this embodiment is 40%.

[0031] Further, the anti-radiation material in this embodiment is a mixture of lead oxide and bismuth oxide.

[0032] Specifically, in this embodiment, the environmentally friendly plasticizer is epoxidized soybean oil; the environmentally friendly antioxidant is 2,6-di-tert-butyl-4-methylphenol.

[0033] It should be noted that in this embodiment, GPE type defoamer is used as defoamer; liquid calcium zinc stabilizer is used as heat stabilizer.

[0034] In addition, in this embodiment, the ultraviolet absorber is specifically 2,2-dihydroxy-4-methoxybenzophenone, and the emulsifier is sodium dodecylbenzenesulfonate.

[0035] The production technology of disposable PVC gloves in the present embodiment, comprises the f...

Embodiment 2

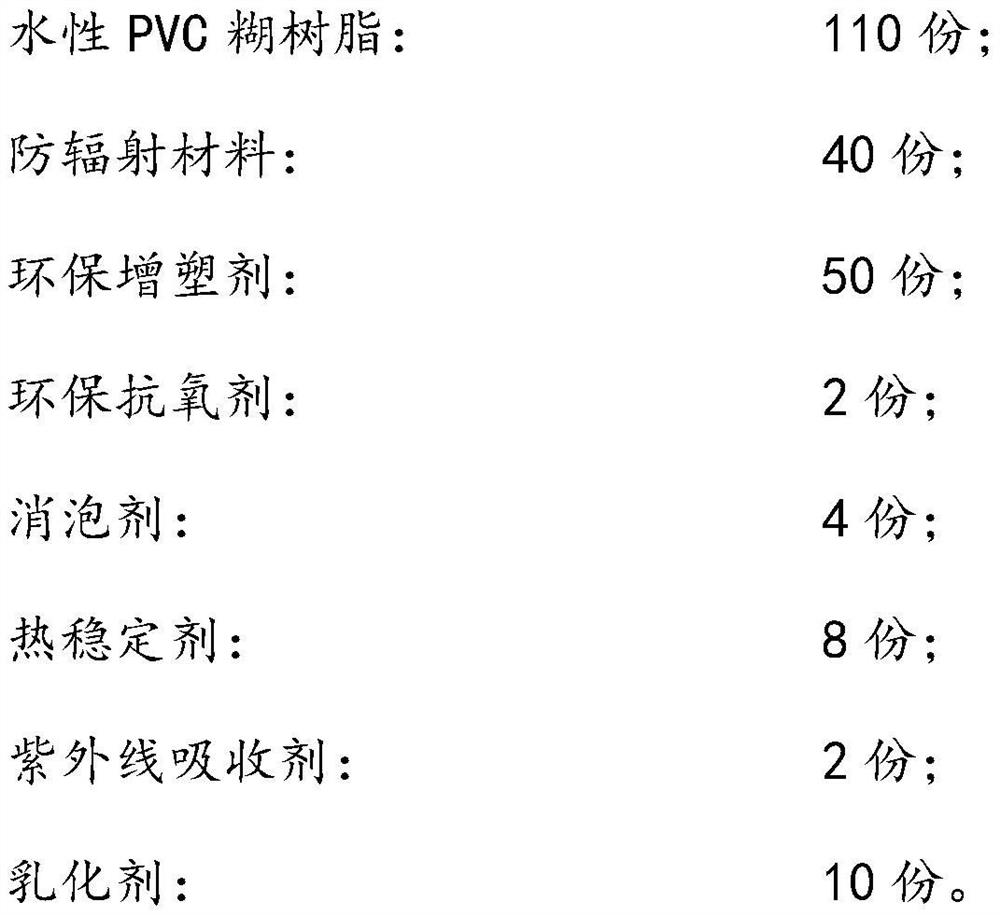

[0045] In a preferred embodiment, disposable PVC gloves comprise the raw material of following weight fraction:

[0046]

[0047]

[0048] It is worth noting that the water content of the water-based PVC paste resin is 35%.

[0049] Further, the anti-radiation material is any one or a mixture of more than one of lead oxide, bismuth oxide, antimony pentasulfide and tungsten disulfide.

[0050] Specifically, the environmentally friendly plasticizer is a mixture of DOP, DINP, DOTP, and DINCH; the environmentally friendly antioxidant is 1,1,3-tris(2-methyl-4-hydroxyl-5-tert-butylphenyl)butane Antioxidant.

[0051] It is worth noting that the defoamer uses phenylethyl alcohol oleate; the heat stabilizer uses an organotin stabilizer.

[0052] In addition, the ultraviolet absorber is specifically 2-2'-hydroxy-3',5'-dipentylphenyl-benzotriazole, and the emulsifier is betaine.

[0053] The production technology of disposable PVC gloves in the present embodiment, comprises the ...

Embodiment 3

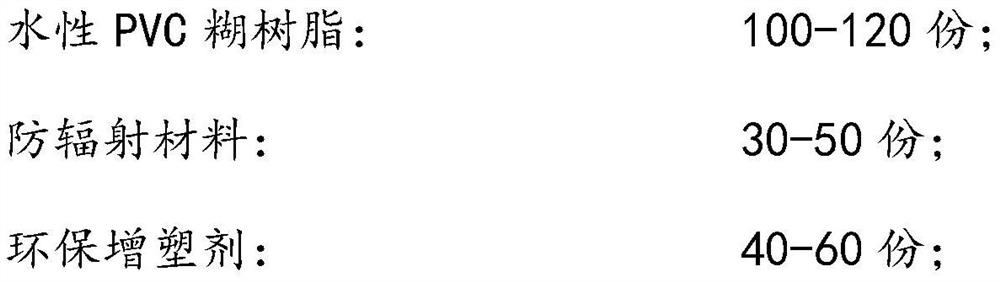

[0063] In a preferred embodiment, disposable PVC gloves comprise the raw material of following weight fraction:

[0064]

[0065] It is worth noting that the water content of the water-based PVC paste resin is 30-60%.

[0066] Further, the anti-radiation material is any one or a mixture of more than one of lead oxide, bismuth oxide, antimony pentasulfide and tungsten disulfide.

[0067] Specifically, the environmentally friendly plasticizer is one or more mixtures of DOP, DINP, DOTP, DINCH, epoxy soybean oil, and chlorine-containing plasticizers; the environmentally friendly antioxidant is 2,6-di-tert-butyl-4 - methylphenol or 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane antioxidant.

[0068] It is worth noting that the defoamer adopts GPE type defoamer, phenylethyl alcohol oleate or lauryl phenylacetate; the heat stabilizer adopts one or more of liquid calcium zinc stabilizer and organotin stabilizer.

[0069] Furthermore, the UV absorber is in particular 2,2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com