Positive sample micropore processing method and application thereof

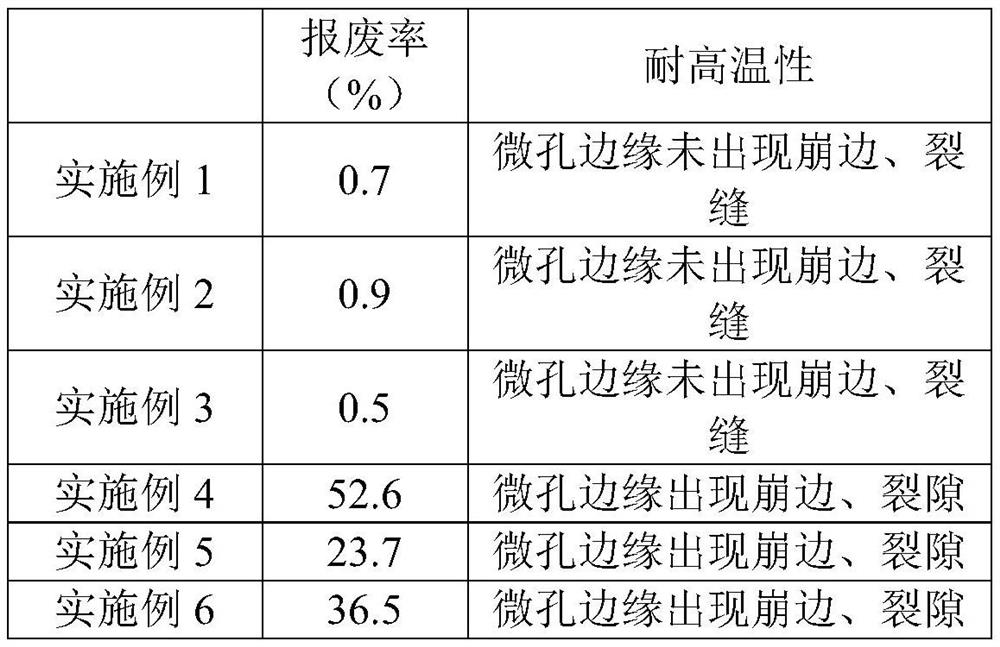

A positive sample, micro-hole processing technology, applied in the direction of metal processing equipment, test sample preparation, sampling, etc., can solve the problems of high labor cost, time-consuming and laborious, high scrap rate, etc., to achieve reduced scrap rate, accurate analysis, avoid harsh effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 of the present invention provides a kind of positive sample micropore processing method, specifically as follows:

[0064] (1) Scanning electron microscope-X-ray energy spectrometer to measure the composition of soda-lime glass, and apply ultrasonic coupling agent to the area to be measured, and use a thickness gauge to analyze the thickness of soda-lime glass;

[0065] (2) Use a laser microhole processing instrument to process microholes in the region where the relative content difference of each element of the soda lime glass is 0-2wt% and the thickness difference is 0-0.02mm.

[0066] The linear thermal expansion coefficient of the soda lime glass at 20-300°C is 8×10 -6 K -1 .

[0067] The parameter conditions for the scanning electron microscope-X-ray energy spectrometer to determine the composition of the soda lime glass are: voltage 15KV, count rate 15cps, scanning time 2min.

[0068] The ultrasonic coupling agent is purchased from Jinnuote Medical...

Embodiment 2

[0070] Embodiment 2 of the present invention provides a kind of positive sample micropore processing method, specifically as follows:

[0071] (1) Scanning electron microscope-X-ray energy spectrometer to measure the composition of soda-lime glass, and apply ultrasonic coupling agent to the area to be measured, and use a thickness gauge to analyze the thickness of soda-lime glass;

[0072] (2) Use a laser microhole processing instrument to process microholes in the region where the relative content difference of each element of the soda lime glass is 2-4wt% and the thickness difference is 0-0.03mm.

[0073] The linear thermal expansion coefficient of the soda lime glass at 20-300°C is 8×10 -6 K -1 .

[0074] The parameter conditions for the scanning electron microscope-X-ray energy spectrometer to determine the composition of the soda lime glass are: voltage 15KV, count rate 15cps, scanning time 4min.

[0075] The ultrasonic coupling agent is purchased from Jinnuote Medical...

Embodiment 3

[0077] Embodiment 3 of the present invention provides a kind of positive sample micropore processing method, specifically as follows:

[0078] (1) Scanning electron microscope-X-ray energy spectrometer to measure the composition of soda-lime glass, and apply ultrasonic coupling agent to the area to be measured, and use a thickness gauge to analyze the thickness of soda-lime glass;

[0079] (2) Use a laser microhole processing instrument to process microholes in the region where the relative content difference of each element of the soda lime glass is 0-1wt% and the thickness difference is 0-0.01mm.

[0080] The linear thermal expansion coefficient of the soda lime glass at 20-300°C is 8×10 -6 K -1 .

[0081] The parameter conditions for the scanning electron microscope-X-ray energy spectrometer to determine the composition of the soda lime glass are: voltage 15KV, count rate 15cps, scanning time 3min.

[0082] The ultrasonic coupling agent is purchased from Jinnuote Medical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com