Double-sided arc additive manufacturing device and method based on numerical simulation and stress monitoring

An additive manufacturing and numerical simulation technology, applied in the field of additive manufacturing, can solve the problems of uneven expansion and contraction of space and time, residual tensile stress, large formed parts, etc., to reduce the waiting time between layers and optimize additive manufacturing. Process, the effect of suppressing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

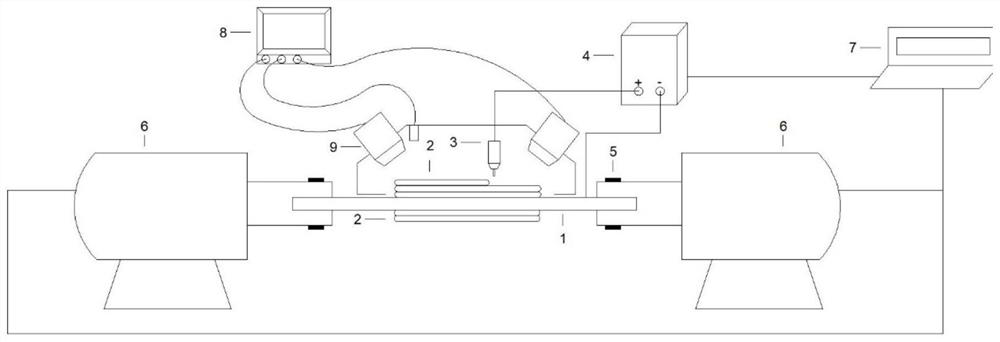

[0050] Example 1: Manufacture of mild steel components using double-sided additives

[0051] The finite element analysis method was used to simulate the initial conditions of the additive manufacturing of 1 layer, 2 layers, and 4 layers, and then obtained the residual stress distribution and stress value of the arc additive manufacturing structural parts and the optimal flipping time. The stress of the final component is minimized by flipping after 2 layers of additive manufacturing.

[0052] Grind the substrate clean with an angle grinder and remove oil stains.

[0053] Install and debug the device, connect the base plate to the side with the rotary positioner through the clamp. The torch strikes the arc on the upper surface of the substrate. The type of welding torch is MAG, the arc current of the welding torch is 180A, the arc voltage is 20V; the diameter of the welding wire is φ1.0mm; the shielding gas of the welding torch is a mixture of argon and carbon dioxide, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com