High-temperature-resistant ultraviolet curing adhesive and preparation method thereof

A UV light curing glue technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems that UV glue cannot be widely used, the molecular chain has less rigid functional groups, and the mechanical properties of materials have declined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

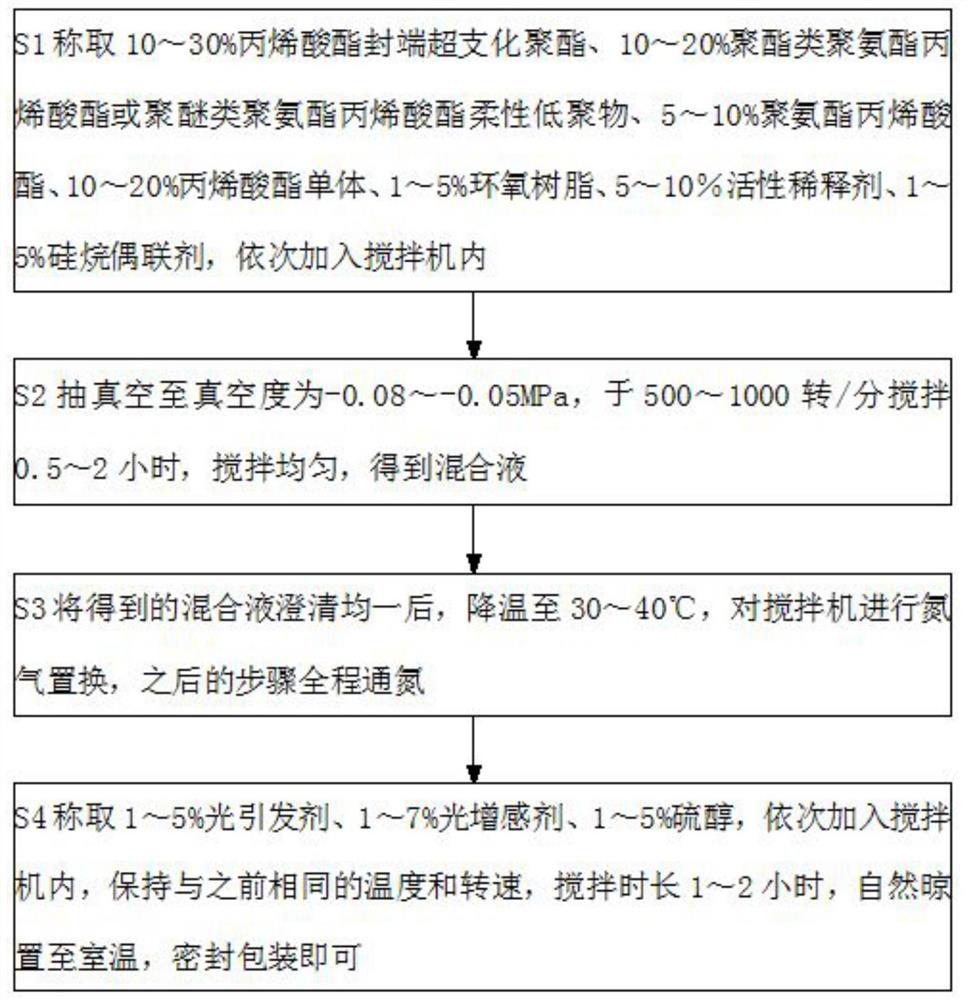

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] refer to figure 1 , a high-temperature UV-curable adhesive, which is composed of the following raw materials in weight percent: 10-30% of acrylate-terminated hyperbranched polyester, polyester urethane acrylate or polyether urethane acrylate flexible oligomer 10-30% 20%, polyurethane acrylate 5~10%, acrylate monomer 10~20%, epoxy resin 1~5%, reactive diluent 5~10%, silane coupling agent 1~5%, photoinitiator 1~ 5%, photosensitizer 1-10%, thiol 1-5%.

[0020] In the present invention, the acrylate-terminated hyperbranched polyester is obtained through a capping reaction between hyperbranched polyester and acrylic acid.

[0021] In the present invention, the ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com