Organic phase change heat storage material and preparation method thereof

A heat storage material and organic phase technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as oxidation thermal conductivity, etc., and achieve the effects of improving cycle stability, solving stratification, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

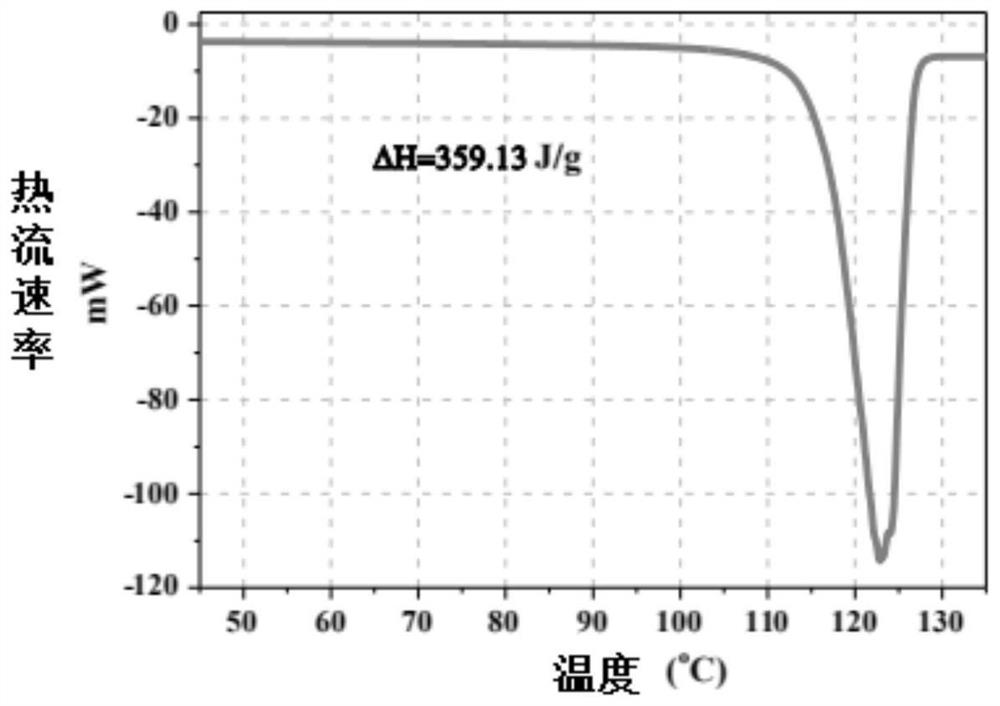

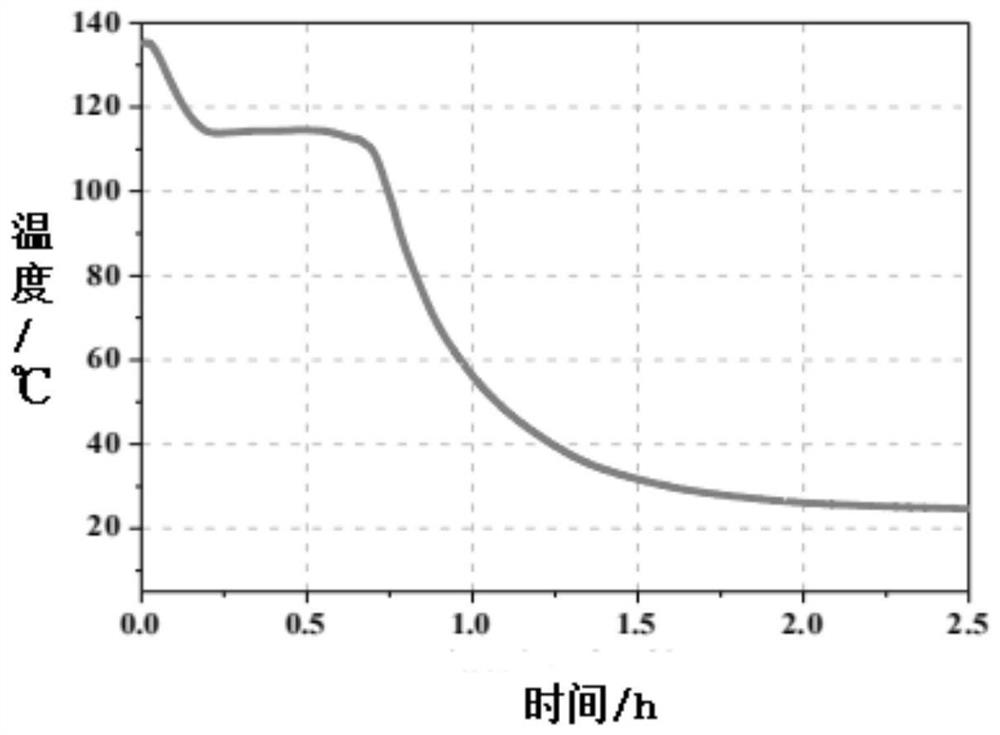

[0042] An organic phase-change heat storage material, which comprises the following components in parts by weight: an organic phase-change material (92g of erythritol), an oxidation inhibitor (1g of ethylenediaminetetraacetic acid di Sodium), thickener (1g of konjac flour, 1g of guar gum), nucleating agent (1g of calcium fluoride, 1g of calcium phosphate), enhanced thermal conductivity material (3g of nano-alumina).

[0043] A method for preparing the above-mentioned organic phase change heat storage material, comprising the steps of:

[0044] Step 1. After heating, stirring and melting the organic phase change material according to the above weight ratio, the heating temperature is 135°C, then adding an oxidation inhibitor and stirring evenly, then adding a thickener and stirring evenly, and the stirring rate is 1000r / min, to obtain The viscous mixture is ready for use;

[0045] Step 2: Add a nucleating agent and an enhanced heat-conducting material to the viscous mixture, sti...

Embodiment 2

[0050] An organic phase-change heat storage material, which comprises the following components in parts by weight: an organic phase-change material (92g of erythritol), an oxidation inhibitor (2g of ethylenediaminetetraacetic acid di Sodium), thickener (1g of konjac flour, 1g of guar gum), nucleating agent (1g of calcium fluoride), enhanced thermal conductivity material (3g of nano-alumina).

[0051] A method for preparing the above-mentioned organic phase change heat storage material, comprising the steps of:

[0052] Step 1. After heating, stirring and melting the organic phase change material according to the above weight ratio, the heating temperature is 135°C, then adding an oxidation inhibitor and stirring evenly, then adding a thickener and stirring evenly, and the stirring rate is 1000r / min, to obtain The viscous mixture is ready for use;

[0053] Step 2: Add a nucleating agent and an enhanced heat-conducting material to the viscous mixture, stir and mix evenly at a s...

Embodiment 3

[0058] An organic phase-change heat storage material, which comprises the following components in parts by weight: an organic phase-change material (92g of xylitol), an oxidation inhibitor (2g of butyl hydroxyanisole), Thickener (1g of konjac flour, 1g of guar gum), nucleating agent (1g of calcium fluoride), enhanced thermal conductivity material (3g of expanded graphite).

[0059] A method for preparing the above-mentioned organic phase change heat storage material, comprising the steps of:

[0060] Step 1. After heating, stirring and melting the organic phase change material according to the above weight ratio, the heating temperature is 135°C, then adding an oxidation inhibitor and stirring evenly, then adding a thickener and stirring evenly, and the stirring rate is 1000r / min, to obtain The viscous mixture is ready for use;

[0061] Step 2: Add a nucleating agent and an enhanced heat-conducting material to the viscous mixture, stir and mix evenly at a stirring rate of 250...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com