Preparation method of low-fat pumpkin crisp chips

A pumpkin chip, low-fat technology, applied in the functions of food ingredients, food ingredients as antioxidants, food heat treatment, etc., can solve the problem of less patent reports on pumpkin chips, air humidity sensitivity of chips, and greater influence of nutrients. To achieve the effect of enriching the flavor of the product, improving the crispness and gloss of the taste, and improving the nutritional functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a production method of vacuum-fried pumpkin chips, the specific steps are:

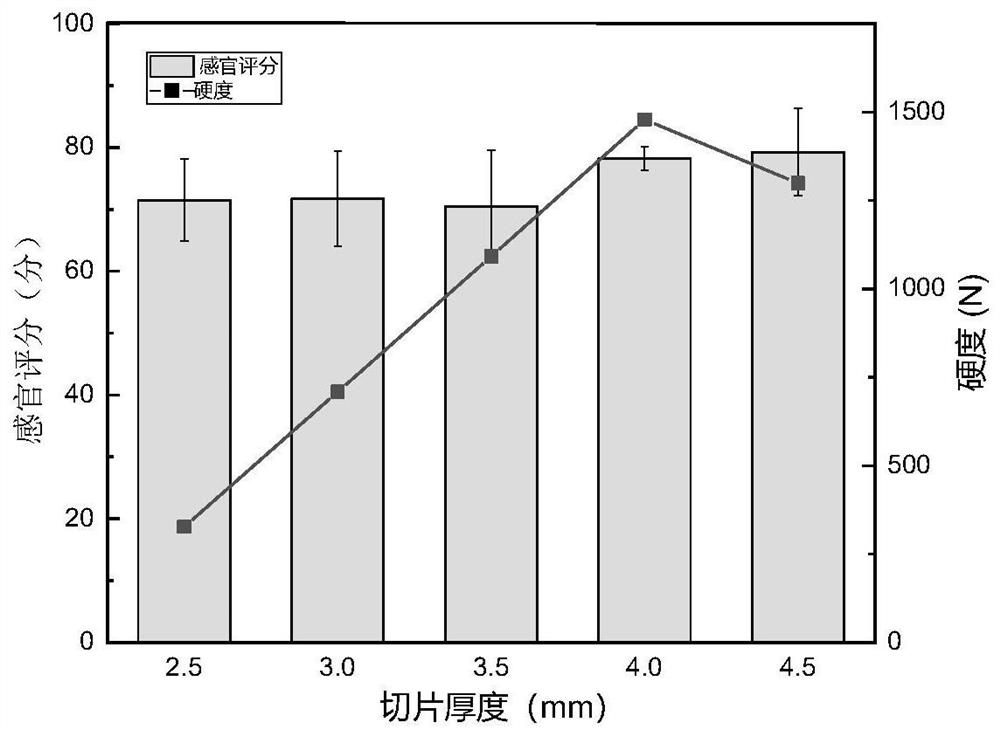

[0042] S1. Prefabricated slices: After the pumpkin is cleaned, remove the upper and lower stalks and the bad skin, then cross-cut to remove the whiskers and seeds, and cut into U-shaped pumpkin slices with a thickness of 4mm;

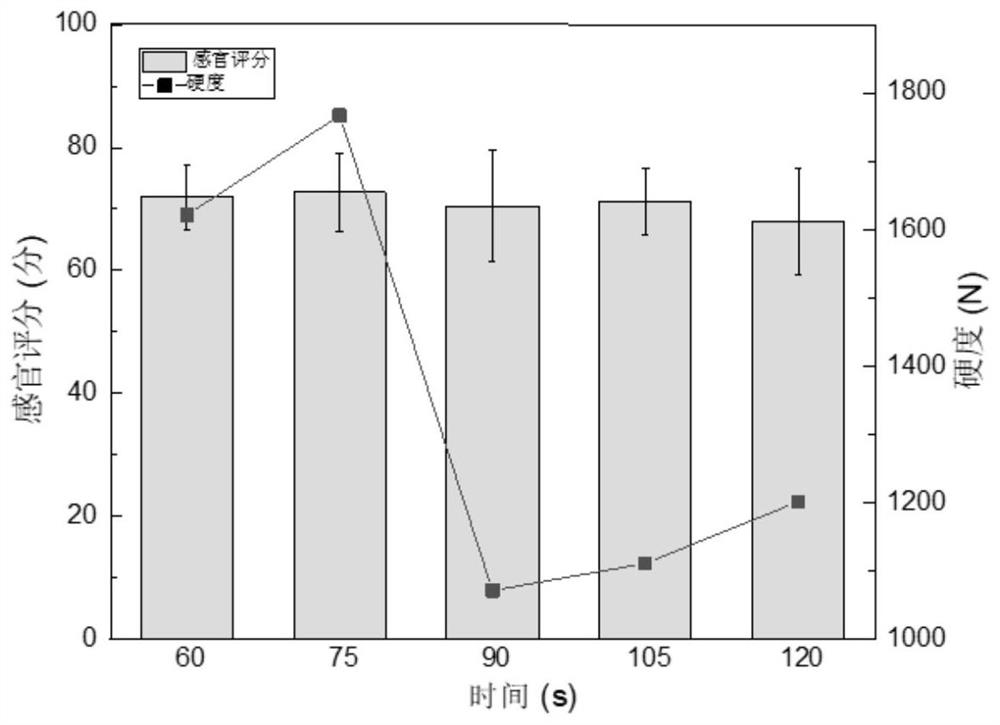

[0043] S2, color-protecting blanching: put the pumpkin slices obtained in step S1 into citric acid containing 0.1% mass concentration, 0.15% vitamin C, 1.0% NaCl and 0.1% CaCl 2 Soak in the solution for 20 minutes, blanched at 85°C for 90 seconds, and cooled to room temperature;

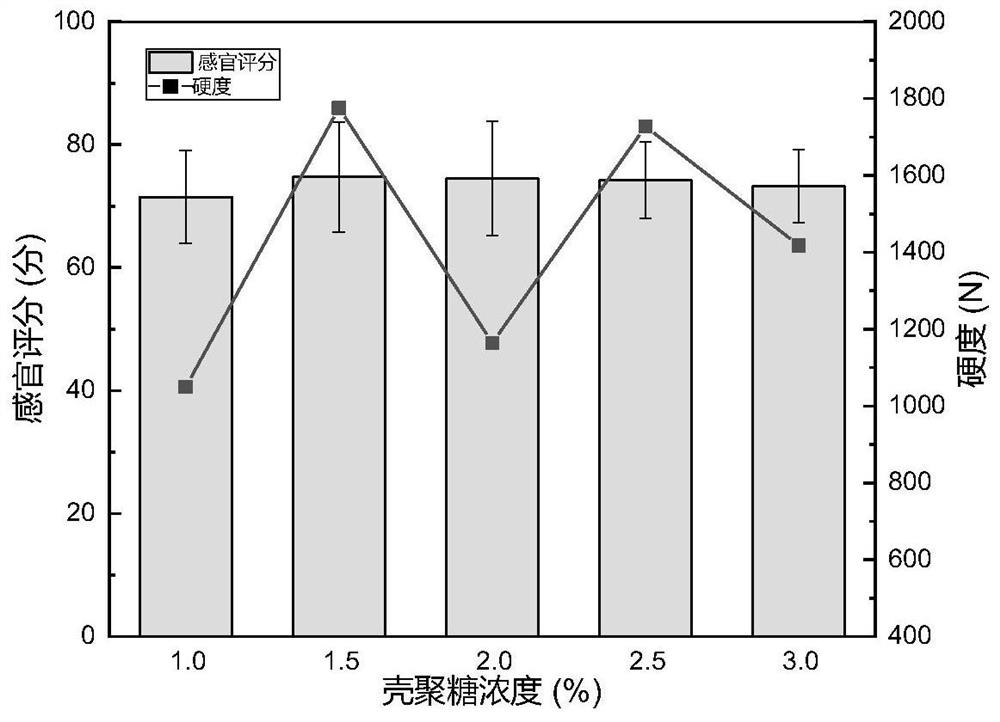

[0044]S3, coating treatment: put the pumpkin slices obtained in step S2 in a place containing 3% white granulated sugar, 10% trehalose, 3% maltitol, 1% chitosan, 0.5% whey protein , 3% soy protein isolate and 0.5% collagen peptide coating solution for 2 hours, soaked in the coating solution and then drained for 1 hour;

[0045] S4, freeze hardening: freeze the pumpkin...

Embodiment 2

[0050] In this embodiment, on the basis of embodiment 1, the thickness of the pumpkin slices in step S1 is changed to 4.5 mm. Other conditions and steps are all the same as in Example 1.

Embodiment 3

[0061] This embodiment provides a production method of vacuum-fried pumpkin chips, the specific steps are:

[0062] S1. Prefabricated slices: After the pumpkin is cleaned, remove the upper and lower stalks and the bad skin, then cross-cut to remove the whiskers and seeds, and cut into U-shaped pumpkin slices with a thickness of 4mm;

[0063] S2, color-protecting blanching: put the pumpkin slices obtained in step S1 into citric acid containing 0.1% mass concentration, 0.15% vitamin C, 1.0% NaCl and 0.1% CaCl 2 Soak in the solution for 20 minutes, blanched at 85°C for 60 seconds, and cooled to room temperature;

[0064] S3, coating treatment: put the pumpkin slices obtained in step S2 in a place containing 3% white granulated sugar, 10% trehalose, 3% maltitol, 1% chitosan, 0.5% whey protein , 3% soy protein isolate and 0.5% collagen peptide coating solution for 2 hours, soaked in the coating solution and then drained for 1 hour;

[0065] S4, freeze hardening: freeze the pumpki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com