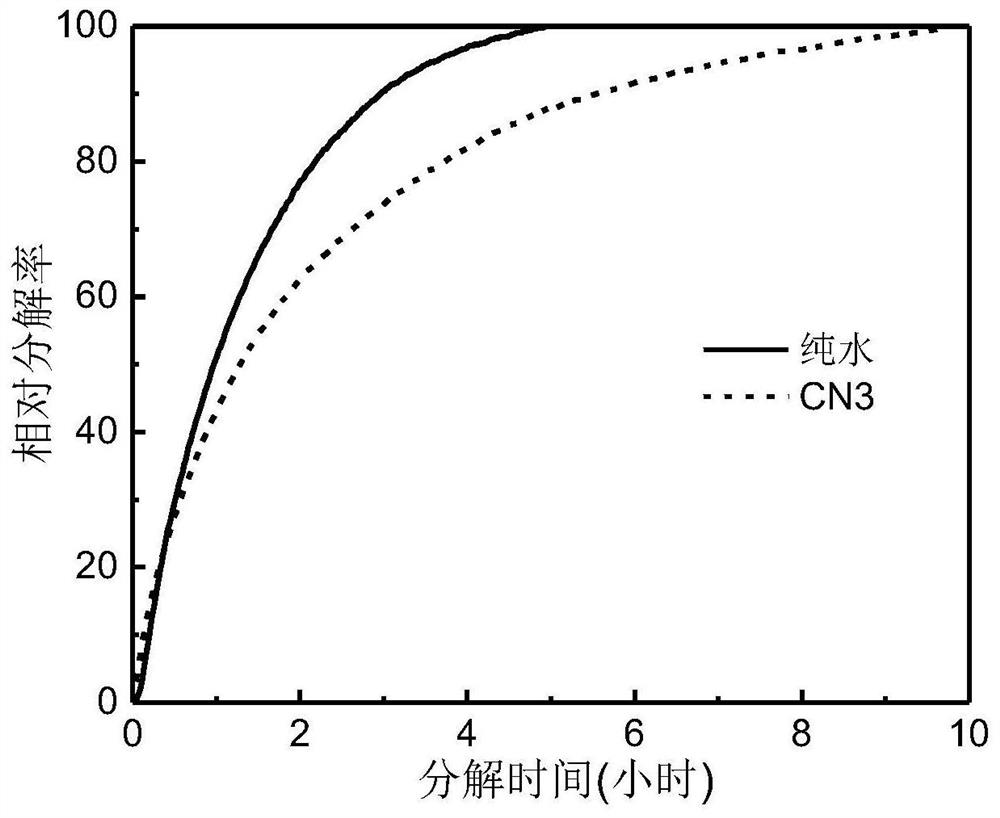

An environmentally friendly natural gas hydrate decomposition inhibitor and its preparation method and application

A technology for decomposing hydrate and natural gas, which is applied in drilling compositions, organic silicon compounds, chemical instruments and methods, etc., can solve the problems that the inhibitory effect needs to be improved, the preparation steps are cumbersome, and it is difficult to degrade. Excellent performance index, enhanced adsorption characteristics, and the effect of inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

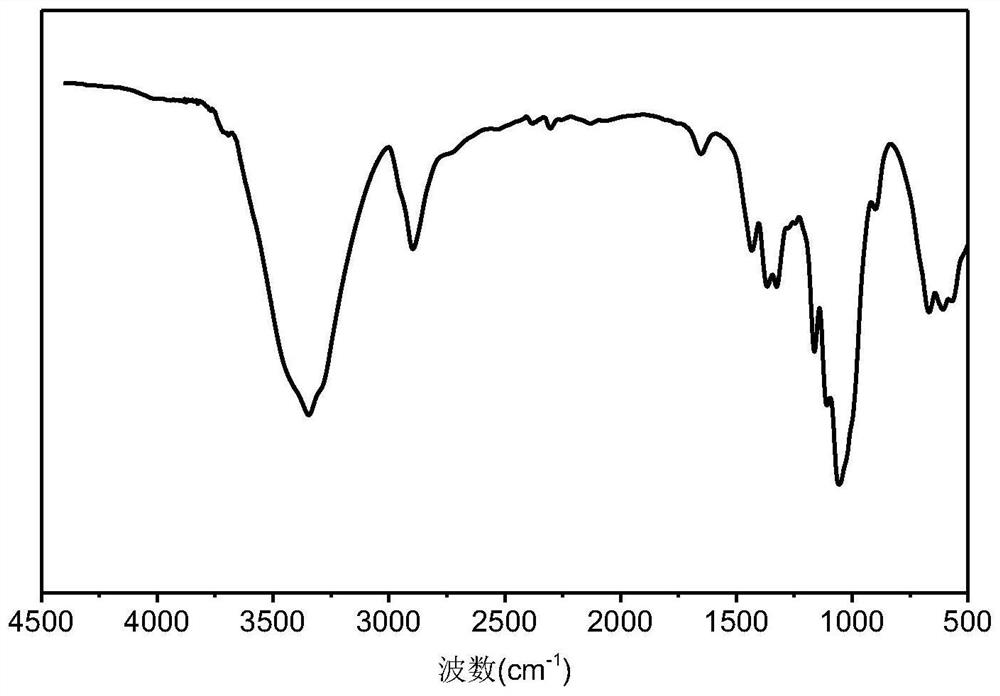

[0039] A preparation method of an environment-friendly natural gas hydrate decomposition inhibitor, comprising the following steps:

[0040] (1) 8g cellulose sample (the ratio of the amount of coupling agent to cellulose monosaccharide unit is 1:10) and 112g deionized water are uniformly mixed at 25°C under the condition that the stirring speed is 200r / min Under stirring for one hour, a cellulose solution was obtained.

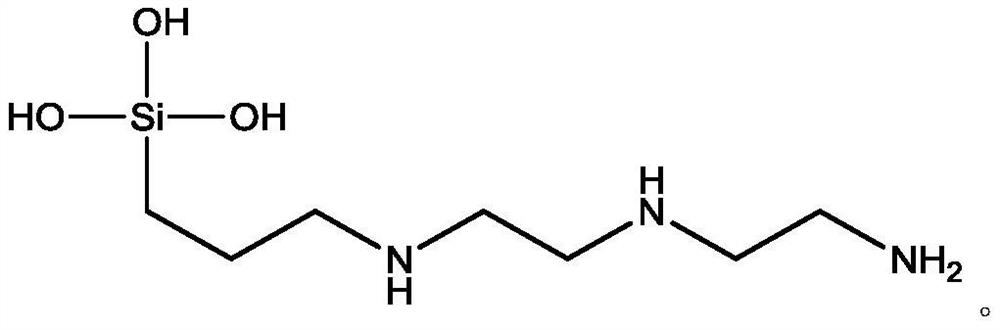

[0041] (2) 1.31g of 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane and 8.69g of deionized water were uniformly mixed at 25°C, and the stirring speed was 200r / min Under the condition of stirring for half an hour, a silane coupling agent solution was obtained.

[0042] (3) Add 10 g of the silane coupling agent solution obtained in step (2) to the cellulose solution obtained in step (1), stir and mix evenly.

[0043] (4) Glacial acetic acid (AR, purity ≥99.5%) was added dropwise at a rate of one drop every half minute, and the pH of the system was adj...

Embodiment 2

[0047] A preparation method of an environmentally friendly natural gas hydrate decomposition inhibitor, comprising the following steps:

[0048] (1) 4g cellulose sample (the ratio of the amount of coupling agent to cellulose monosaccharide unit is 1:10) and 116g deionized water are uniformly mixed at 25°C under the condition that the stirring speed is 200r / min Under stirring for two hours, a cellulose solution was obtained.

[0049] (2) 0.66g of 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane and 9.34g of deionized water were uniformly mixed at 25°C, and the stirring speed was 200r / min Under the condition of stirring for half an hour, a silane coupling agent solution was obtained.

[0050] (3) Add 10 g of the silane coupling agent solution obtained in step (2) to the cellulose solution obtained in step (1), stir and mix evenly.

[0051] (4) Glacial acetic acid (AR, purity ≥99.5%) was added dropwise at a rate of one drop every half minute, and the pH of the system ...

Embodiment 3

[0054] A preparation method of an environmentally friendly natural gas hydrate decomposition inhibitor, comprising the following steps:

[0055] (1) 8g cellulose sample (the ratio of the amount of coupling agent to cellulose monosaccharide unit is 1:10) and 112g deionized water are uniformly mixed at 15°C under the condition that the stirring speed is 300r / min Under stirring for one hour, a cellulose solution was obtained.

[0056] (2) 1.31g of 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane was uniformly mixed with 8.69g of deionized water at 25°C, and the stirring speed was 200r / min. The mixture was stirred for half an hour to obtain a silane coupling agent solution.

[0057] (3) Add 10 g of the silane coupling agent solution obtained in step (2) to the cellulose solution obtained in step (1), stir and mix evenly.

[0058] (4) Glacial acetic acid (AR, purity ≥99.5%) was added dropwise at a rate of one drop every half minute, and the pH of the system was adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com