Lavender essence microcapsule finishing liquid

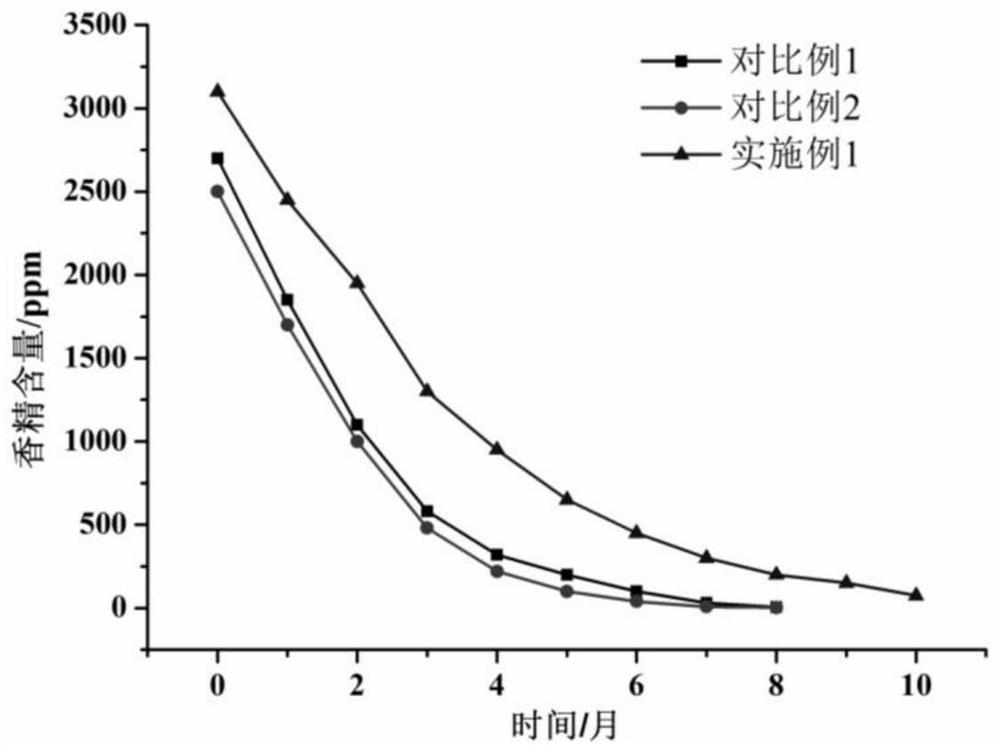

A fragrance microcapsule and lavender technology, applied in fiber treatment, biochemical fiber treatment, wear-resistant fiber, etc., can solve the problems of low affinity of fabric fibers, low mechanical strength of capsule wall, low fragrance wrapping rate, etc., to improve softness , Enhance the effect of health care, enhance the effect of health care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

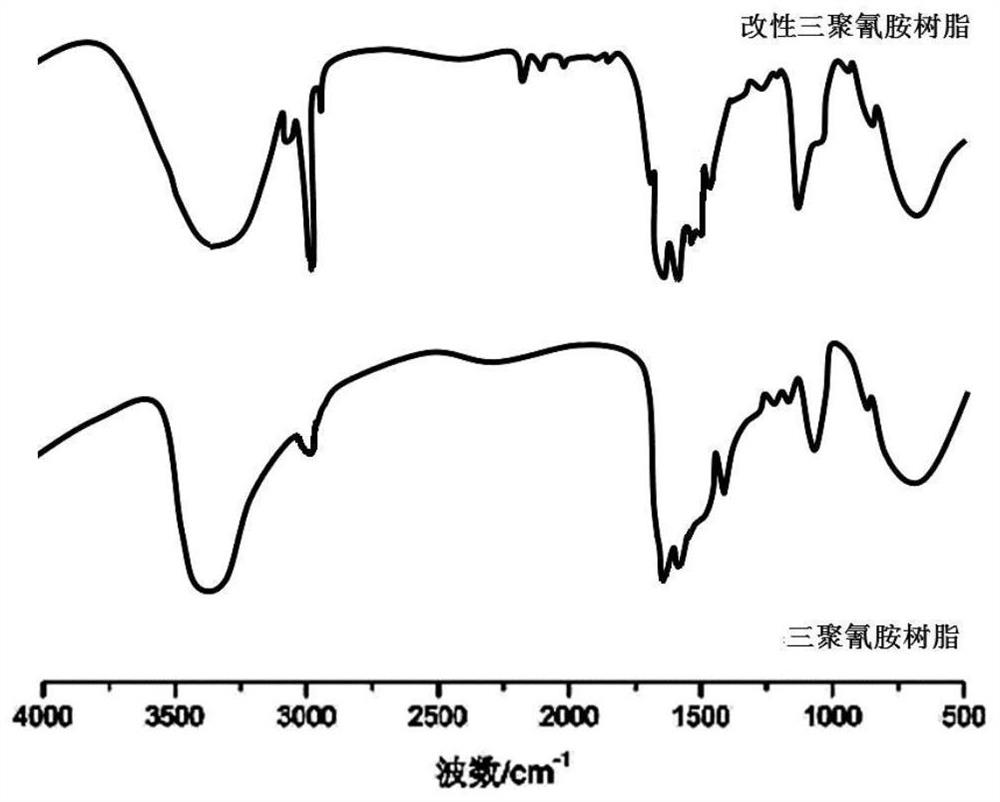

[0037] Preparation of modified melamine resin:

[0038] Weigh melamine resin and epresteramine (the mass ratio of melamine resin to epresteramine is 1:2.8) and dissolve them in DMF (the solid-to-liquid ratio of melamine resin to DMF is 1:17 g / mL). , slowly drop DMAP (the mass ratio of DMAP to melamine resin is 1.2:1), react for 10 minutes, then add EDC (the mass ratio of melamine resin to EDC is 1:1.1), naturally raise the temperature to 23°C, and react for 20 hours. Thin layer chromatography (TLC) was used to check whether the reaction was complete. The reactant was poured into water, extracted with ethyl acetate and washed with saturated brine respectively, the organic phase was dried overnight with anhydrous sodium sulfate, filtered, and separated by silica gel column chromatography (eluents were ethyl acetate and petroleum ether, the volume ratio was 1:2), vacuum-dried after vacuum distillation to obtain modified melamine resin.

[0039] Preparation of a lavender essence...

Embodiment 2

[0047] The difference between the preparation of modified melamine resin and Example 1 is that the mass ratio of melamine resin to epresteramine is 1:2.5, and other conditions are fine-tuned according to the actual situation of the reaction;

[0048] The difference between the preparation of a kind of lavender essence microcapsule and embodiment 1 is:

[0049] The core-to-wall ratio in the microcapsule structure is 1.1:1;

[0050] The amount of polymer emulsifier in step S1 is 14.1% of the total mass of lavender essence; the emulsification time is 12min; the stirring speed is 14500r / min;

[0051] In step S2, the pH value of the emulsion is adjusted to 4.5 with acetic acid; the constant temperature is 60° C., and the temperature is kept for 1 hour.

[0052] The average particle size of the prepared microcapsules is 3.0 μm, and the particle size distribution is 1.0-3.5 μm.

[0053] The finishing solution is: 0.5% of lavender essence microcapsules (calculated by water weight), ...

Embodiment 3

[0057] The difference between the preparation of modified melamine resin and Example 1 is that the mass ratio of melamine resin to epresteramine is 1:2.6, and other conditions are fine-tuned according to the actual situation of the reaction;

[0058] The difference between the preparation of a kind of lavender essence microcapsule and embodiment 1 is:

[0059] The core-to-wall ratio in the microcapsule structure is 1.4:1;

[0060] The amount of polymer emulsifier in step S1 is 14.7% of the total mass of lavender essence; the emulsification time is 10min; the stirring speed is 14000r / min;

[0061] In step S2, the pH value of the emulsion is adjusted to 5.0 with acetic acid; the constant temperature is 63° C., and the temperature is kept for 1.5 hours.

[0062] The average particle size of the prepared microcapsules is 2.5 μm, and the particle size distribution is 0.5-3.0 μm.

[0063] The finishing solution is: 0.6% of lavender essence microcapsules (calculated by water weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com