Feed for improving protein efficiency of tilapia mossambica

A tilapia and protein technology, which is applied in feed, animal feed, animal feed, etc., can solve the problems of reducing the production efficiency of feed pellet machines, affecting the integrated operation of pellet machines, and inconvenient for collection and transportation of feed pellets, so as to achieve integration The effect of operation, scientific ratio is rich, easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A feed for improving the protein efficiency of tilapia, comprising the following raw materials in parts by weight: 17 parts of fish meal, 46 parts of soybean meal, 15 parts of peanut cake, 4 parts of corn gluten meal, 9 parts of cassava flour, 11 parts of chicken liver meal, seaweed 4 parts of soybean powder, 3 parts of soybean lecithin oil, 5 parts of dried brewer's grains, 0.3 parts of astaxanthin, 0.2 parts of choline chloride, 0.8 parts of sodium humate, 0.3 parts of vitamin E, 0.2 parts of vitamin C acetate and compound mineral 0.7 parts of the substance, the composite minerals are formed by mixing magnesium sulfate, ferrous citrate, manganese sulfate, potassium chloride and yeast selenium in a weight ratio of 2.5:2:1:1:0.3.

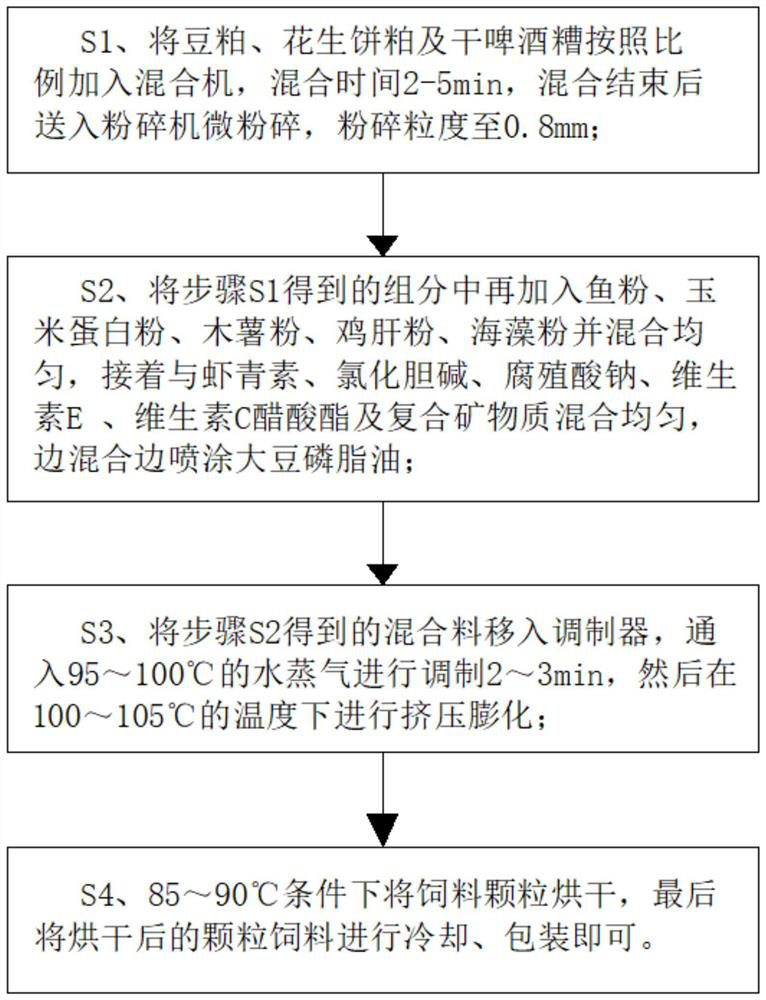

[0050] A feed preparation process to improve tilapia protein efficiency, such as figure 1 shown, including the following steps:

[0051] S1. Add soybean meal, peanut cake and dried brewer's grains into the mixer according to the proportion, ...

Embodiment 2

[0071] On the basis of Example 1, such as Figure 11 As shown, the bottom edge of one end face of the collecting trolley 3 is provided with a feeding port 32, and the peripheral edge of the feeding port 32 is provided with a clamping groove 33, and the central inner surface of the clamping groove 33 is provided with a third threaded hole 31, and the lower The top edge of the feed port 32 is rotated to install a limit sealing plate 34, and the side, bottom, and center of the limit sealing plate 34 are screw-connected with a third fastening screw 30.

[0072] When this embodiment is in use, when there are too many feed particles inside the aggregate trolley 3 and need to be removed, first separate the aggregate trolley 3 from one end of the support frame 11, and then push the handle 28 to drive the aggregate trolley 3 to move to the feeder. In the collection area, turn the third fastening screw 30 in the opposite direction to separate from the third threaded hole 31 in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com