Pt-Cu/ZnO plasma photocatalyst as well as preparation method and application thereof

A technology of plasma and photocatalyst, which is applied in the field of ionic photocatalyst and its preparation, can solve the problems of limited photoresponse range and light utilization rate of simple noble metals, and achieve easy control of the preparation process, light utilization rate, and particle distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

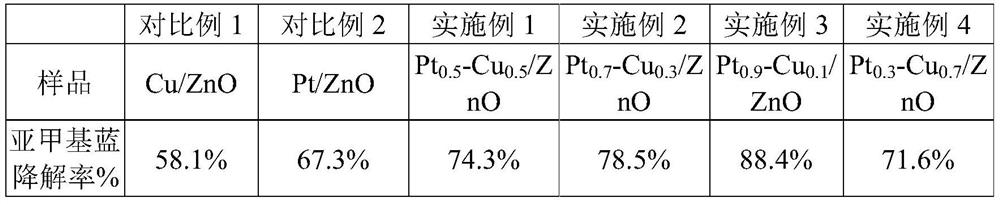

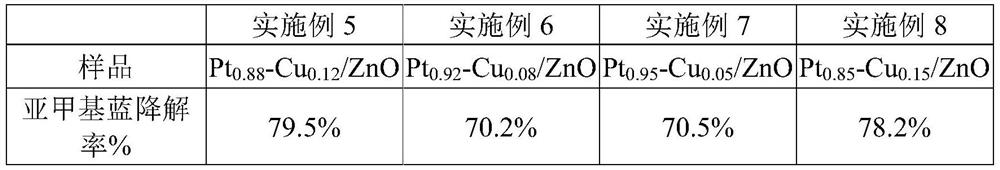

Embodiment 1

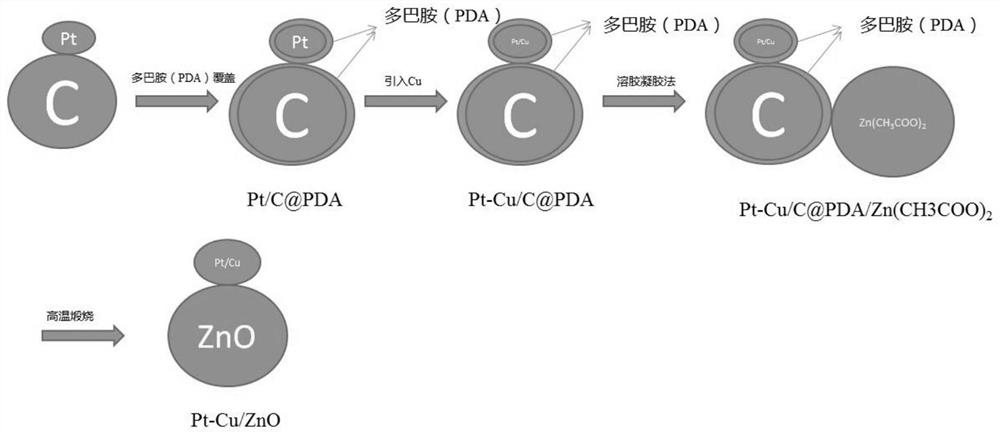

[0027] 1. Preparation of Pt-Cu alloy: Add 49mg of Pt / C (10wt% Pt) catalyst (Aladdin) to ethanol aqueous solution with a volume fraction of 75%, ultrasonically stir at room temperature for 1 hour until uniformly dispersed, then add 40mg of dopamine (PDA) , stirred at room temperature for 4h, added 10ml of 5wt% polyvinylpyrrolidone aqueous solution (PVP-K30), 6ml of acetonitrile, 4ml of 0.1mol / L ascorbic acid aqueous solution, and added dropwise 2.5ml of 0.01mol / LCuCl 2 aqueous solution, after reacting for 1 h, the solid was obtained by filtration, and centrifuged and washed three times with deionized water to obtain Cu 0.5 -Pt 0.5 / C@PDA.

[0028] 2. Preparation of sol-gel: Add 1.8g of zinc acetate into 50ml of 75% ethanol aqueous solution by volume fraction, add 30ml of ethyl acetate solution, heat and stir to raise the temperature to 70°C, stir for 0.5h, and add the obtained product in step (1) All of the Cu / Pt / C@PDA was stirred at a constant temperature of 70°C to 20mL sol...

Embodiment 2

[0032] 1. Preparation of Pt-Cu alloy: Add 69mg of Pt / C (10wt% Pt) catalyst (Aladdin) to 75% volume fraction ethanol aqueous solution, ultrasonically stir at room temperature for 1h until uniformly dispersed, then add 40mg of dopamine (PDA) , stirred at room temperature for 5h, added 12ml of 3wt% polyvinylpyrrolidone aqueous solution (PVP-K30), 8ml of acetonitrile, 1ml of 0.1mol / L ascorbic acid aqueous solution, and added dropwise 1.5ml of 0.01mol / LCuCl 2 Aqueous solution, after reacting for 2 hours, filtered to obtain solid, centrifuged and washed three times with deionized water to obtain Cu 0.3 -Pt 0.7 / C@PDA.

[0033] 2. Preparation of sol-gel: Add 1.8g of zinc acetate into 50ml of 75% ethanol aqueous solution by volume fraction, add 30ml of ethyl acetate solution, heat and stir to raise the temperature to 75°C, stir for 0.5h, and add the obtained product in step (1) All Cu / Pt / C@PDA was stirred at a constant temperature of 70°C to 20ml sol state, and dried in a drying oven...

Embodiment 3

[0036] 1. Preparation of Pt-Cu alloy: Add 88mg of Pt / C (10wt% Pt) catalyst (Aladdin) to an aqueous ethanol solution with a volume fraction of 75%, ultrasonically stir at room temperature for 2 hours until uniformly dispersed, then add 40mg of dopamine (PDA) , stirred at room temperature for 5h, added 10ml 8wt% polyvinylpyrrolidone aqueous solution (PVP-K30), 10ml acetonitrile, 1ml 0.1mol / L ascorbic acid aqueous solution, and added dropwise 0.5ml 0.01mol / LCuCl 2 Solution, after reacting for 2h, filtered to obtain the solid, centrifuged and washed three times with deionized water to obtain Cu 0.1 -Pt 0.9 / C@PDA.

[0037] 2. Preparation of sol-gel: Add 1.8g of zinc acetate into 50ml of 75% ethanol aqueous solution by volume fraction, add 30ml of ethyl acetate solution, heat and stir to raise the temperature to 80°C, stir for 0.5h, and add the obtained product in step (1) All Cu / Pt / C@PDA was stirred at 80°C to 20ml sol state, and dried in a drying oven at 100°C for 12h.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com